Step-by-step lifting free-dividing cotton topping machine

A topping machine and stepping motor technology, applied in agricultural machinery and implements, cutting tools, cutting equipment, etc., can solve problems such as unsatisfactory field work effects, complicated control of the lifting system, and insufficient adjustment accuracy, so as to simplify the power source , Reduce labor intensity, reduce the effect of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

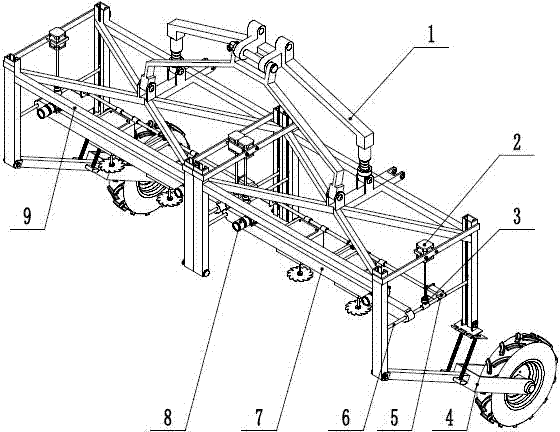

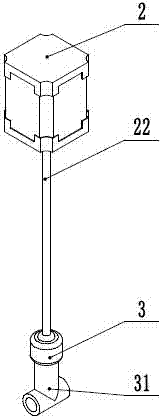

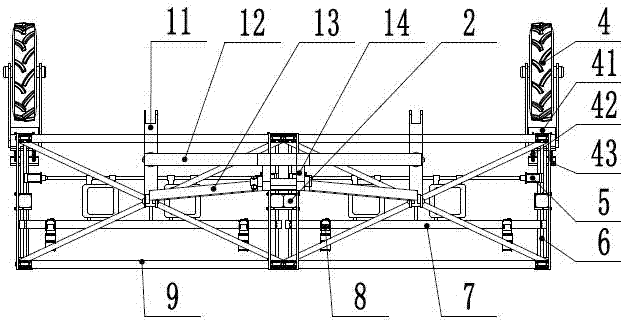

[0030] Example: refer to Attached picture 1 ~ 6 , the present invention is made of frame 9, suspension device, step-by-step lifting device, walking device, free-separation grain sliding topping device and industrial camera 8; Shock suspension frame 12 is located at the front portion of frame 9, and cable stay 13 is located at the rear portion of shock absorption suspension frame 12; 6 structure, the linear stepper motor 2 is arranged inside the frame 9, the roller bearing 3 is arranged at the lower part of the linear stepper motor 2, the lifting ring 31 is arranged at the lower part of the roller bearing 3, the roller bearing 3 is connected with the linear stepping motor 2 and the lifting ring 31 links to each other, and pulley bar 6 is engaged with suspension ring 31; Described running device is made of rotating plate 41, spring 42, ground wheel 4, walking frame 43, and rotating plate 41 is located at frame 9 bottoms, and spring 42 is located at rotating plate 41 Bottom,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com