A double-roller machine and a method for recycling blocks by using the roller machine

A block and roller technology, which is applied in the field of double roller machines and the use of roller machines to recover blocks, can solve the problems of difficulty in ensuring that blocks are prepared into fine particles, difficult to recycle, and block cracks, and can solve the problem of motor blockage. , The effect of fast processing speed and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] In the method for recovering blocks using a roller machine in the present invention, the processed blocks are screened, and the cracked or damaged blocks are first broken into fragments of about 5 cm by using a jaw crusher, and then passed through double rollers. The machine makes the fragments into powdered blocks with a size less than 1 cm, and finally replaces the sand with the powdered materials, mixes lime and water, and processes them into new blocks.

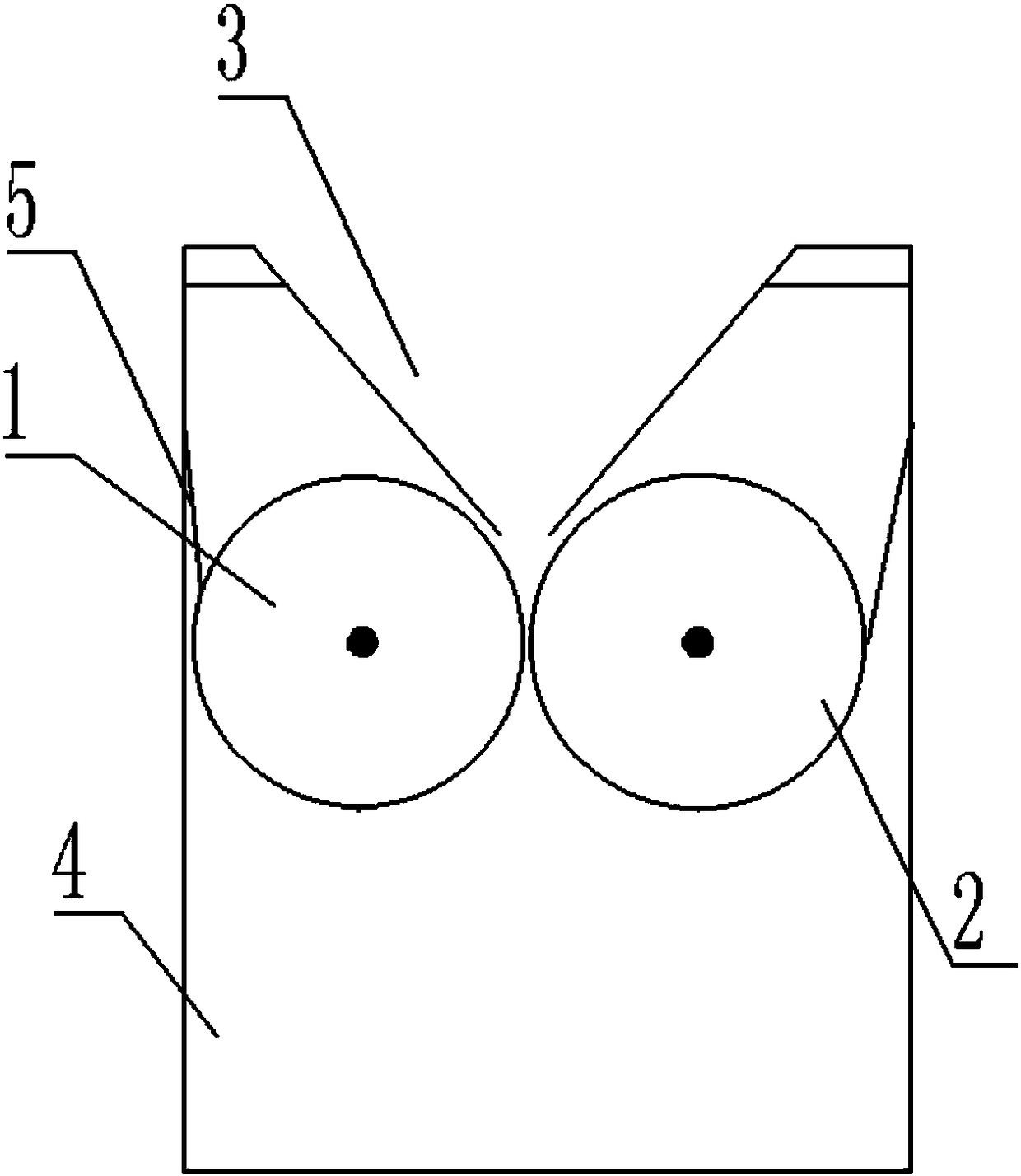

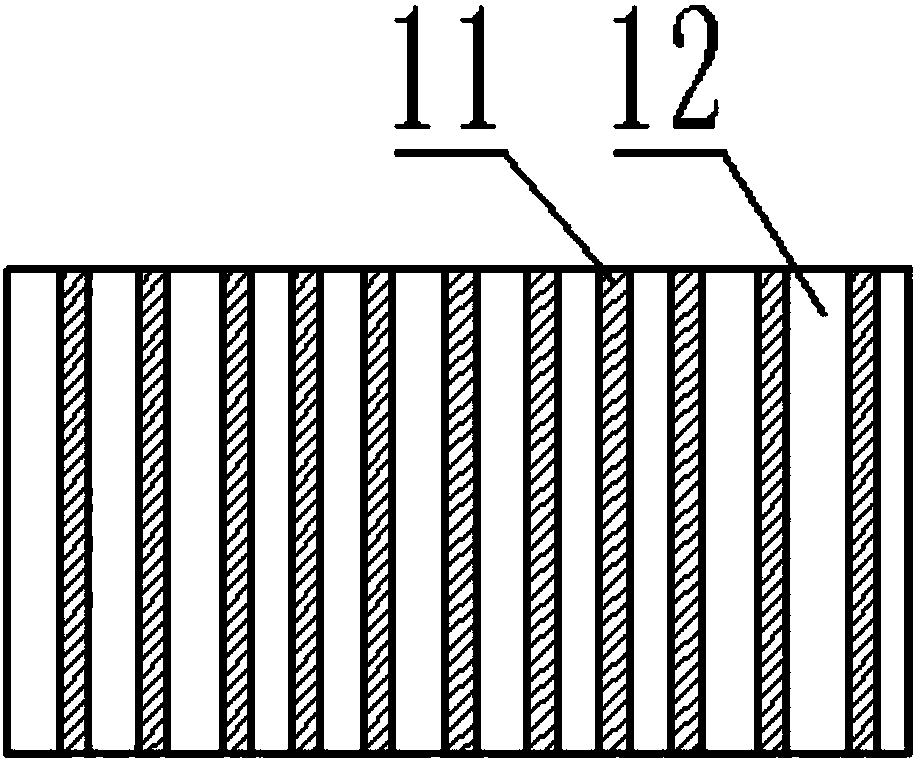

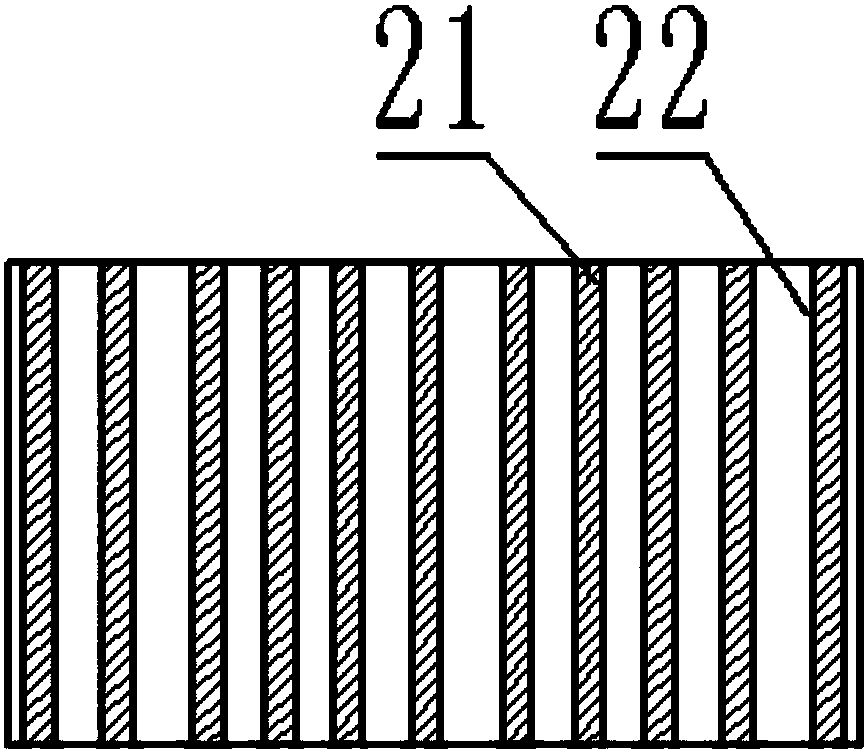

[0022] The double roller machine of the present invention comprises a first roller 1, a second roller 2, a feed hopper 3, a collection box 4, a scraper 5, and the bottom of the feed hopper 3 is arranged between the first roller 1 and the second roller 2 rollers, The collection box 4 is located at the bottom of the first roller 1 and the second roller 2 . The distance between the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com