Steel wire on-line processing production line

A production line and steel wire technology, applied in metal extrusion cleaning equipment, metal extrusion, grinding machines, etc., can solve the problems of reduced production line processing efficiency, pollution of pickling phosphating liquid, unfavorable process processing, etc., to improve quality, Extend phosphating time and increase the effect of washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

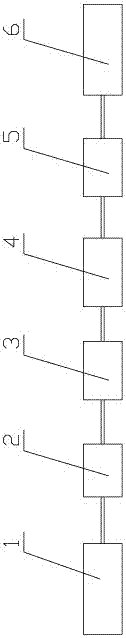

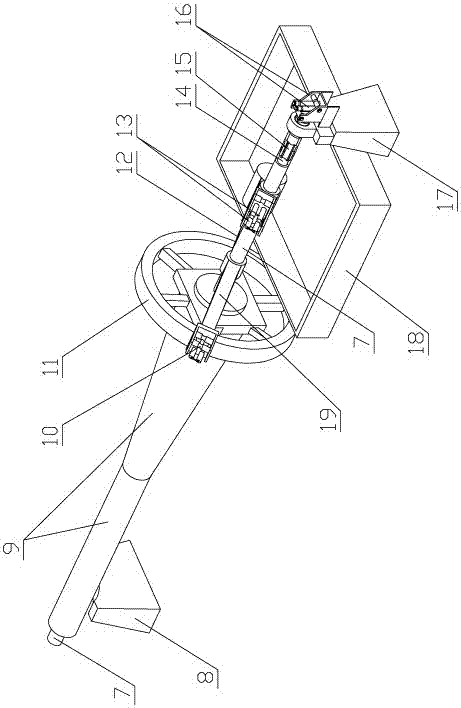

[0045] see Figure 1-Figure 16 , the present invention is an online steel wire processing production line, which sequentially includes an automatic wire management device 1, a peeling device 2, a rust removal device 3, a rapid phosphating device 4, a steel wire surface treatment device 5 and a steel wire drawing machine 6, Steel wire 24 passes through above-mentioned device successively, wherein:

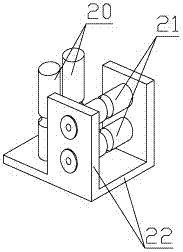

[0046] The automatic wire management device has front and rear two bases 8 and 17, and a steel wire coil shelf and a steel wire straightening device are successively erected between the front and rear two bases, and the steel wire coil rack includes The stop plate 11 and the steel wire rest tube 9, one end of the steel wire rest tube is placed on the front base, and the other end of the steel wire rest tube is fixedly connected with the stop disc; the steel wire straightening device has a rotating shaft tube 7, One end of the rotating shaft tube is installed on the rear base throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com