Pneumatic manipulator

A technology of pneumatic manipulators and cylinders, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of low work efficiency and low yield of wax molds, achieve balanced strength, high yield, and eliminate potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

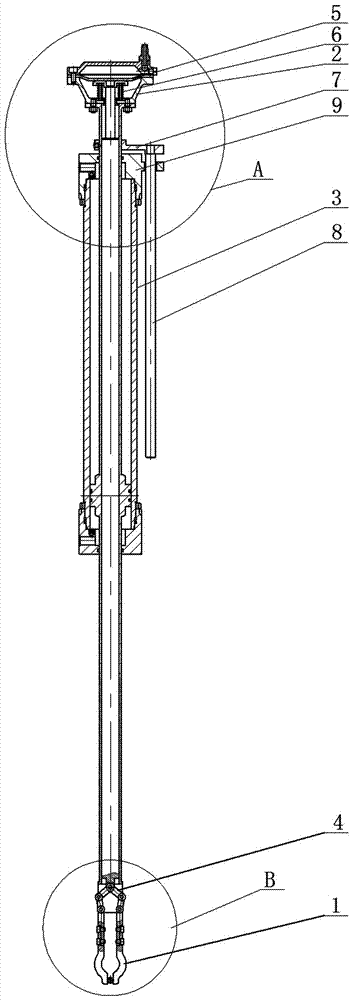

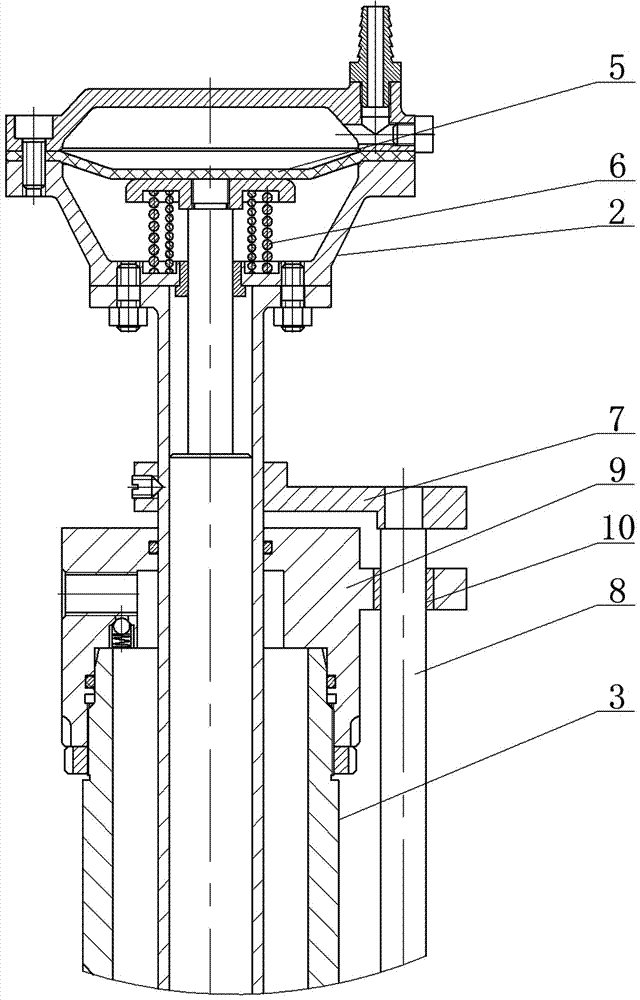

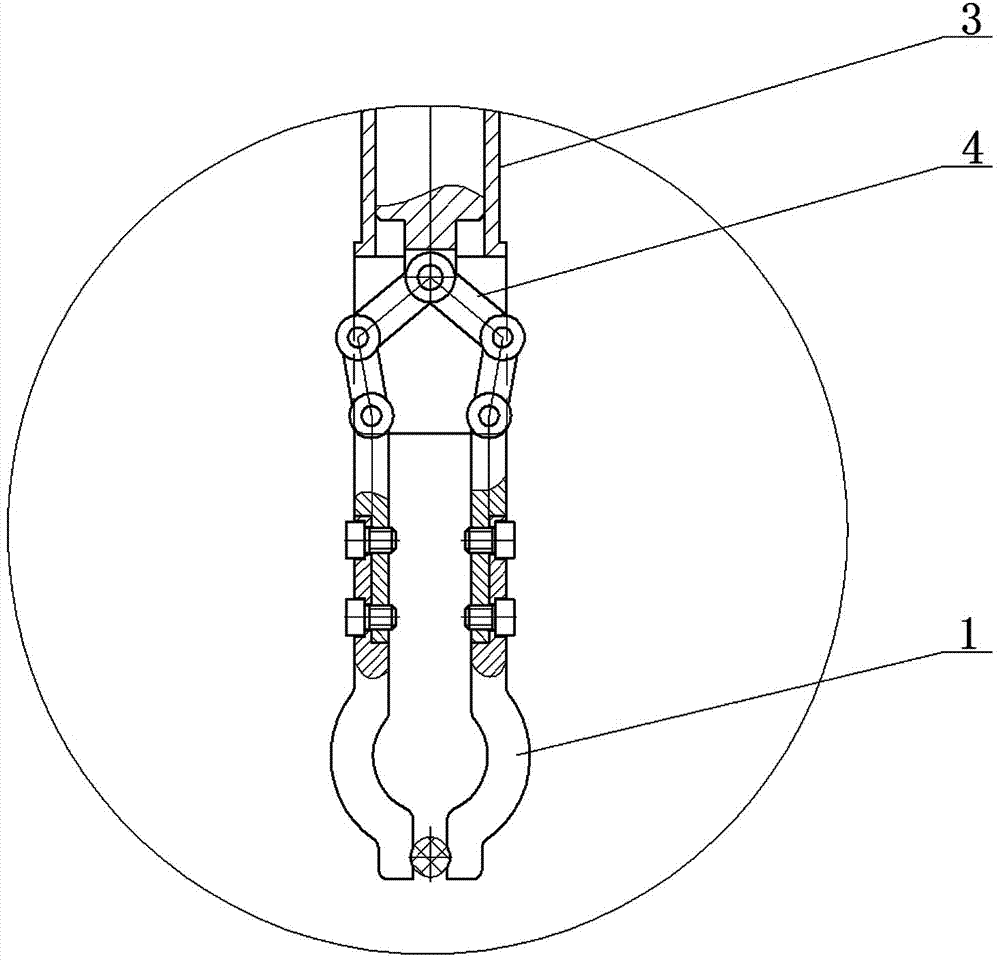

[0014] Depend on Figure 1 ~ Figure 4 As shown, a pneumatic manipulator includes two symmetrical clamps 1, clamp cylinder 2 and lifting cylinder 3, the piston rod of the lifting cylinder 3 is tubular, and the two clamps 1 are hinged on the lifting cylinder 3 The lower end of the piston rod, the upper ends of the two clamps 1 are respectively hinged with two connecting rods 4, the upper ends of the two connecting rods 4 are hinged with the lower end of the piston rod of the clamp cylinder 2, and the clamp cylinder 2 is fixed on the upper end of the piston rod of the lifting cylinder 3 And the piston rod of the clamp cylinder 2 is located in the piston rod of the lifting cylinder 3 and runs through the piston rod of the lifting cylinder 3. The clamp cylinder 2 is a diaphragm type single-acting cylinder, and the clamp cylinder 2 includes a diaphragm 5, and the diaphragm 5 is b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com