Coating with high solid content and high fluorine content and preparation process thereof

A technology with solid content and high solid content, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of low fluorine content, low solid content, and environmental pollution, and achieve high fluorine content, low pollution, and low VOC Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: formula and preparation method

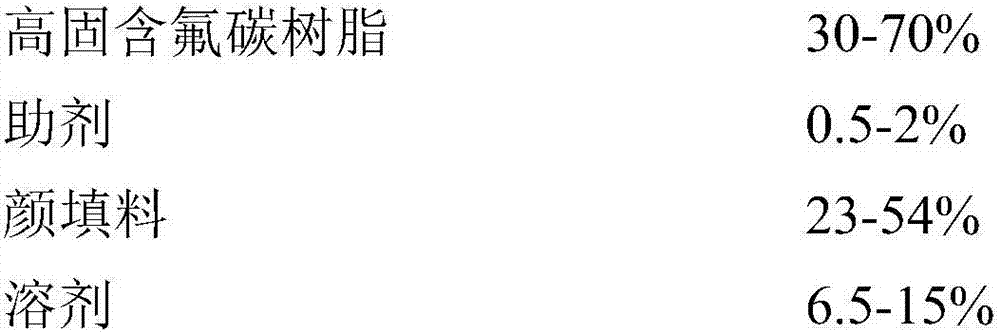

[0025] formula:

[0026] component one finished product

[0027]

[0028] Component Second Finished Product

[0029] Hardener 17%

[0030] Craftsmanship:

[0031] Take 50% of the high-solid fluorocarbon resin in the formula, add solvents and some additives, disperse for 10-30 minutes, add pigments and fillers and disperse for 10-30 minutes, then start grinding, grind to 10-20 microns, add the remaining high-solid fluorine Carbon resin and additives, dispersed for 15-30 minutes, filtered and packaged into component one finished product.

[0032] The curing agent is packaged separately as a second-component finished product.

[0033] In this embodiment, the solid content of the fluorocarbon resin is 75%, the solid content of component one finished product is 75%, the fluorine content of the fluorocarbon resin is 29.5%, and the solid content of the curing agent is 75%.

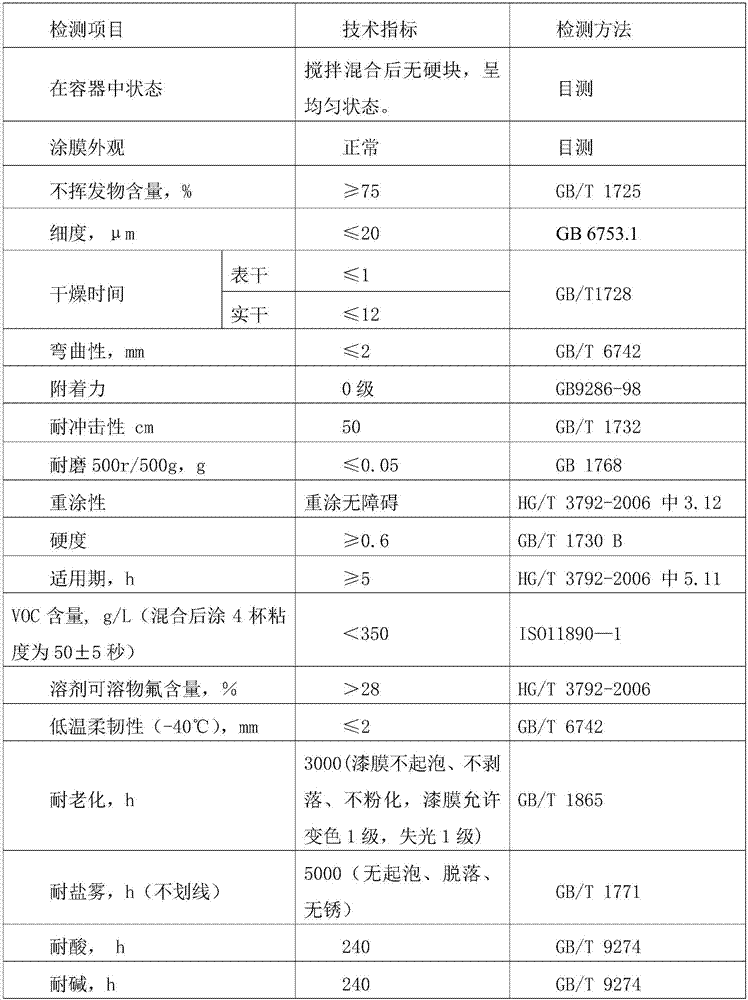

[0034] The typical performance characteristics ...

Embodiment 2

[0038] Embodiment 2: formula and preparation method

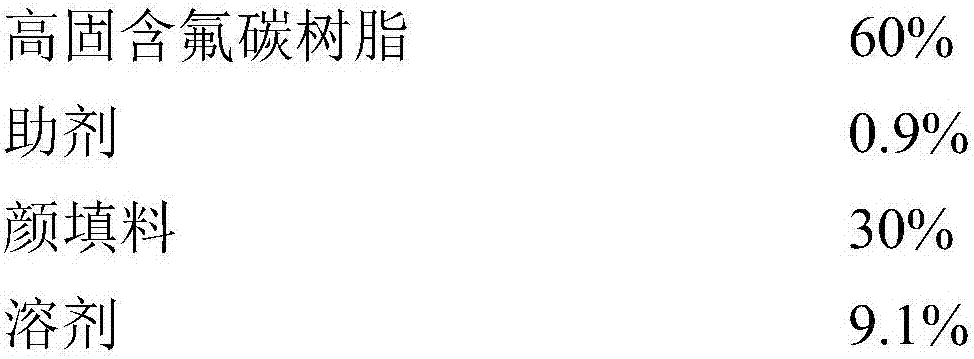

[0039] formula:

[0040] component one finished product

[0041]

[0042] Component Second Finished Product

[0043] Hardener 10%

[0044] Craftsmanship:

[0045] Take 50% of the high-solid fluorocarbon resin in the formula, add solvents and some additives, disperse for 10-30 minutes, add pigments and fillers and disperse for 10-30 minutes, then start grinding, grind to 10-20 microns, add the remaining high-solid fluorine Carbon resin and additives, dispersed for 15-30 minutes, filtered and packaged into component one finished product.

[0046] The curing agent is packaged separately as a second-component finished product.

[0047] In this embodiment, the solid content of the fluorocarbon resin is 72%, the solid content of component one finished product is 75.6%, the fluorine content of the fluorocarbon resin is 28%, and the solid content of the curing agent is 100%.

[0048] Compared with Table 1 in Example 1, the...

Embodiment 3

[0049] Embodiment 3: formula and preparation method

[0050] formula:

[0051] component one finished product

[0052]

[0053] Component Second Finished Product

[0054] Hardener 20%

[0055] Craftsmanship:

[0056] Take 50% of the high-solid fluorocarbon resin in the formula, add solvents and some additives, disperse for 10-30 minutes, add pigments and fillers and disperse for 10-30 minutes, then start grinding, grind to 10-20 microns, add the remaining high-solid fluorine Carbon resin and additives, dispersed for 15-30 minutes, filtered and packaged into component one finished product.

[0057] The curing agent is packaged separately as a second-component finished product.

[0058] In this embodiment, the solid content of the fluorocarbon resin is 77%, the solid content of component one finished product is 76.9%, the fluorine content of the fluorocarbon resin is 31%, and the solid content of the curing agent is 87.5%.

[0059] Compared with Table 1 in Example 1, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com