Dry bonding medical adhesive tape and preparation method thereof

A technology of dry bonding and adhesive tape, which is applied in the medical field, can solve problems such as failure to integrate dry electrodes and dry bonding technology, increase manufacturing cost, and complicated manufacturing process, so as to achieve enhanced comfort and safety and low manufacturing cost , The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

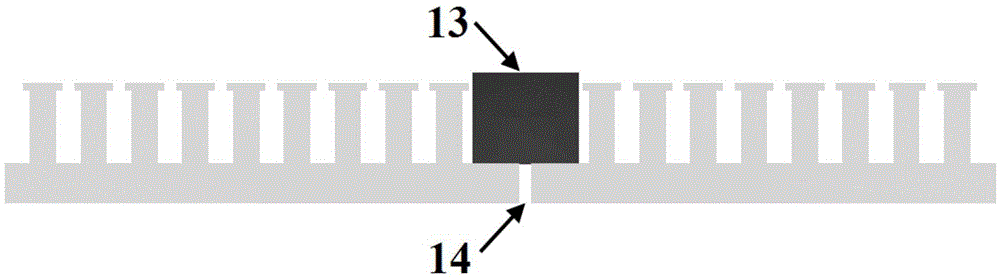

[0031] This embodiment relates to a kind of dry bonding medical adhesive tape, and described medical adhesive tape is the polymer film that has array structure micron scale mushroom-shaped column, and described polymer is polydimethylsiloxane, and wherein described polymer film is set There is an embedded part for integrating dry electrodes, the thickness of the polymer film is 10 um, and the diameter of the micron mushroom-shaped pillar is 2 um.

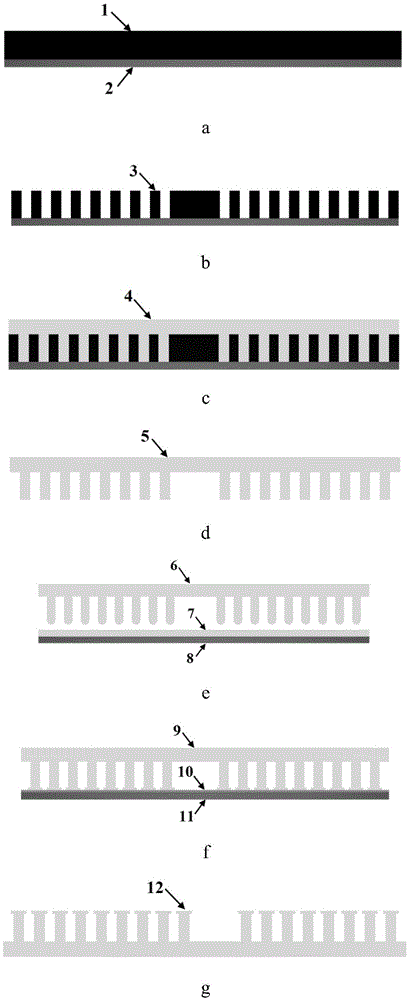

[0032] This embodiment also relates to the preparation method of the aforementioned dry bonding medical adhesive tape, the method comprising the following steps: figure 1 Shown:

[0033] Step 1: Spin-coat SU-8 negative resist with a thickness of 10um on the first silicon wafer, dry it at 60°C for 2 hours, expose and develop with UV light, and obtain an array hole structure with a pore size of 2um Template (SU-8 negative glue template);

[0034] Step 2, cast polydimethylsiloxane on the array hole structure template (SU-8 negative p...

Embodiment 2

[0038] This embodiment relates to a kind of dry bonding medical adhesive tape, and described medical adhesive tape is the polymer film that has array structure micron scale mushroom-shaped column, and described polymer is polydimethylsiloxane, and wherein described polymer film is set There is an embedded part for integrating dry electrodes, the thickness of the polymer film is 50um, and the diameter of the micron mushroom-shaped pillar is 10um.

[0039] This embodiment also relates to the preparation method of the aforementioned dry bonding medical adhesive tape, the method comprising the following steps: figure 1 Shown:

[0040] Step 1: Spin-coat SU-8 negative resist with a thickness of 50um on the first silicon wafer, dry it at 80°C for 4 hours, expose and develop with UV light, and obtain an array hole structure with a pore size of 10um Template (SU-8 negative glue template);

[0041]Step 2, cast polydimethylsiloxane on the array hole structure template (SU-8 negative gl...

Embodiment 3

[0045] This embodiment relates to a kind of dry bonding medical adhesive tape, and described medical adhesive tape is the polymer film that has array structure micron scale mushroom-shaped column, and described polymer is polydimethylsiloxane, and wherein described polymer film is set There is an embedded part for integrating dry electrodes, the thickness of the polymer film is 40um, and the diameter of the micron mushroom-shaped pillar is 8um.

[0046] This embodiment also relates to the preparation method of the aforementioned dry bonding medical adhesive tape, the method comprising the following steps: figure 1 Shown:

[0047] Step 1: Spin-coat SU-8 negative resist with a thickness of 30um on the first silicon wafer, dry it at 70°C for 3 hours, expose and develop with UV light, and obtain an array hole structure with a pore size of 8um Template (SU-8 negative glue template);

[0048] Step 2, cast polydimethylsiloxane on the array hole structure template (SU-8 negative glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com