Processing method for reducing methanol content in fruit fermented wine with high pectin content

A processing method and methanol content technology, applied in the field of fruit fermented wine processing, can solve the problem of low added value and achieve the effect of increasing ethanol content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

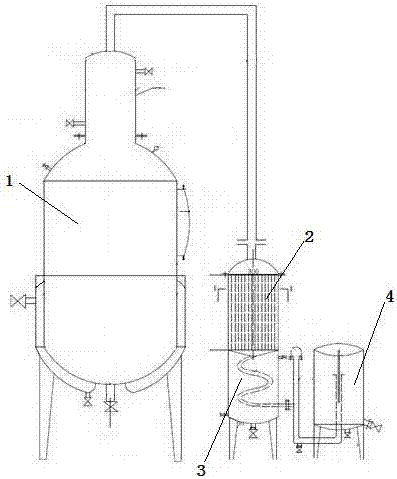

[0016] Such as figure 1 Shown, the present invention is realized like this, and its method step is:

[0017] 1. Improve the ethanol content of mash before distillation Processing method:

[0018] (1) Selection of raw materials: choose fresh fruits as raw materials, which require high sugar content, strong aroma, nine-percent maturity, no pests, and no moldy and rotten fruits;

[0019] (2) Raw material processing: extract juice or pulp manually or mechanically;

[0020] (3) Adjust the sugar content: add the separated pulp or fruit juice into warm water, adjust the sugar content to 25% with white sugar, and then carry out conventional constant temperature fermentation;

[0021] (4) Increase the ethanol content of the fermented mash to above 16%vol;

[0022] (5) Distillation: The fermented mash is distilled by a special multi-stage temperature-controlled distillation device, the temperature of the mash is raised to the boiling point of methanol, and the temperature is 64.7°C-8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com