Dry friction external control four-gear transmission

A dry friction, transmission technology, applied in the direction of vehicle gearbox, gear transmission, transmission components, etc., can solve the problems of low shift success rate, large shift impact, and high failure probability, achieve high mechanical efficiency, reduce friction and heat generation , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0049] Its design concept is to divide the transmission into a clutch part and a gearbox part. The clutch part is the dry part, which is characterized by no lubricating oil; the gearbox part is the wet part, which is characterized by lubricating oil; Department, and shift actuators and brake components are arranged in the stem.

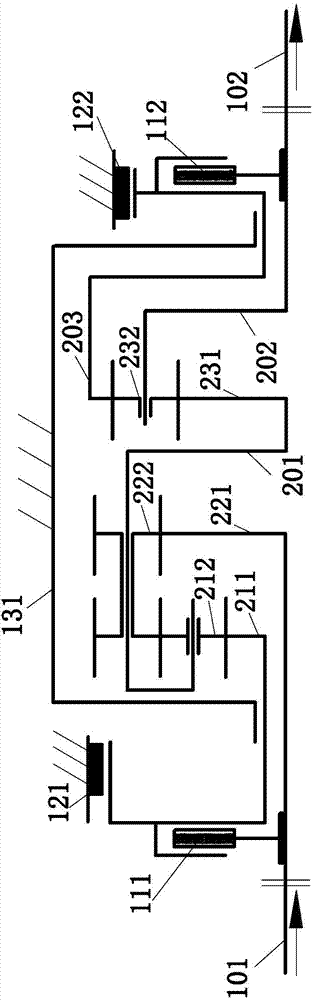

[0050] Please also refer to figure 1 ,Such as figure 1 It can be seen that a preferred embodiment of the present invention is a dry friction externally controlled four-speed transmission, including a shift control element outside the box and a planetary gear transmission, and the planetary gear transmission includes a first gear group, second gear set, third gear set, first planet carrier, second planet carrier,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com