Construction method of underground heat transfer pipe of ground source heat pump system

A technology of ground source heat pumps and construction methods, applied in heat pumps, pipe laying and maintenance, lighting and heating equipment, etc., can solve problems such as water leakage, heat transfer tubes that cannot be placed vertically, and loose joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

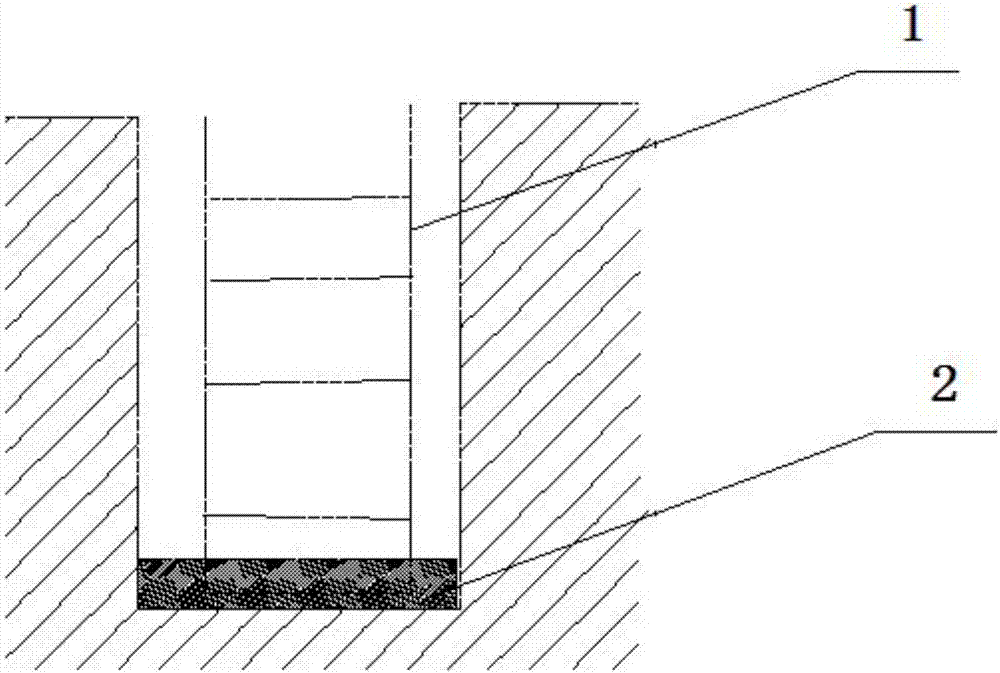

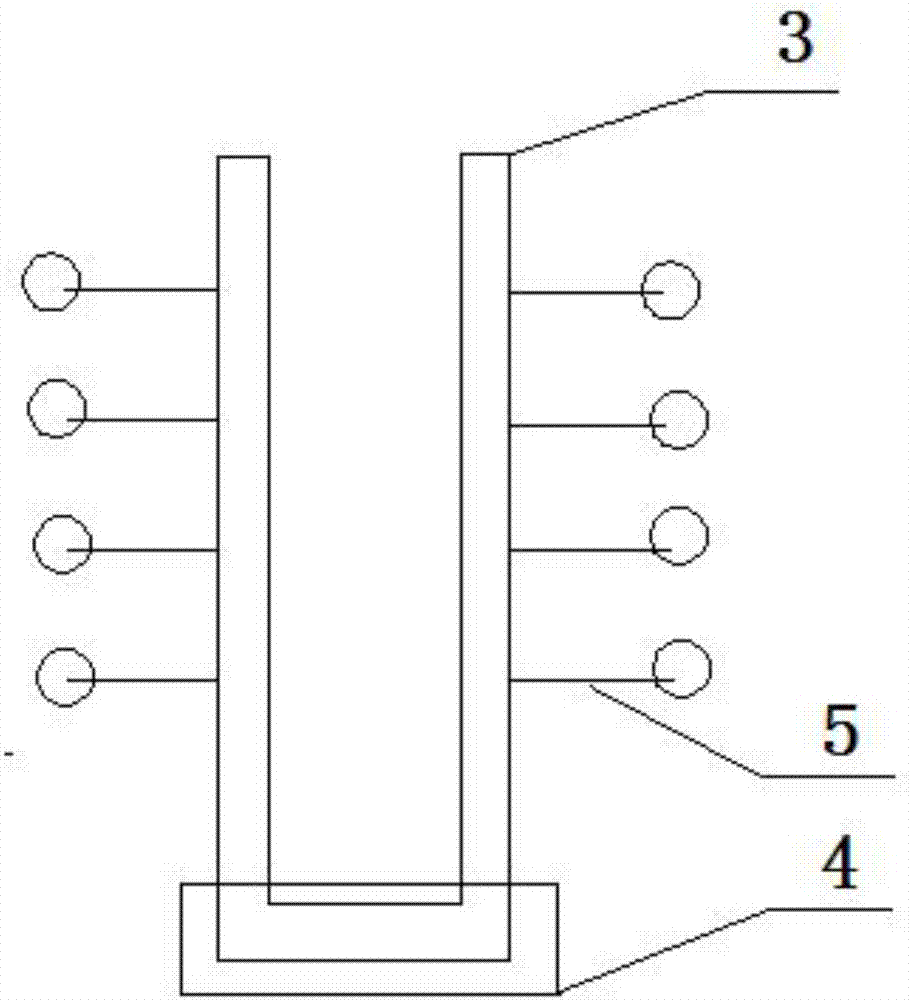

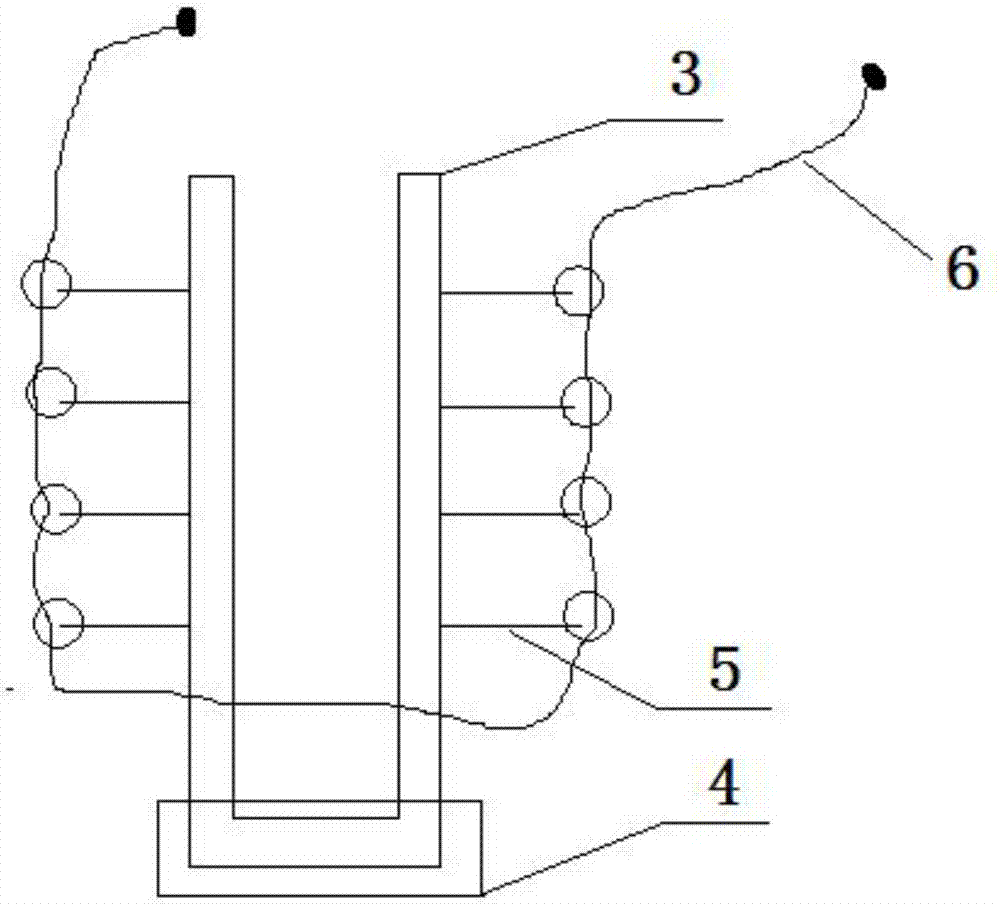

[0023] Embodiment: A construction method for underground heat transfer pipes of a ground source heat pump system, characterized in that it includes a ground source heat pump unit, an indoor exhaust device, and an underground heat transfer unit; the underground heat transfer unit includes heat transfer pipes, connecting head, a plurality of elastic fixing units; the connecting head is used to connect the bottom port of each heat transfer tube; the elastic fixing unit includes a spring and a ring, and one end of the spring is fixed on the tube wall of the heat transfer tube, The other end is provided with a ring; the outer wall of the heat transfer tube is provided with a plurality of elastic fixing units at equal intervals, and the elastic fixing units are perpendicular to the axial direction of the heat transfer tube;

[0024] Specific construction method:

[0025] Step 1), prepare a rope, one end of the rope does not move, and the other end of the rope passes through the ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com