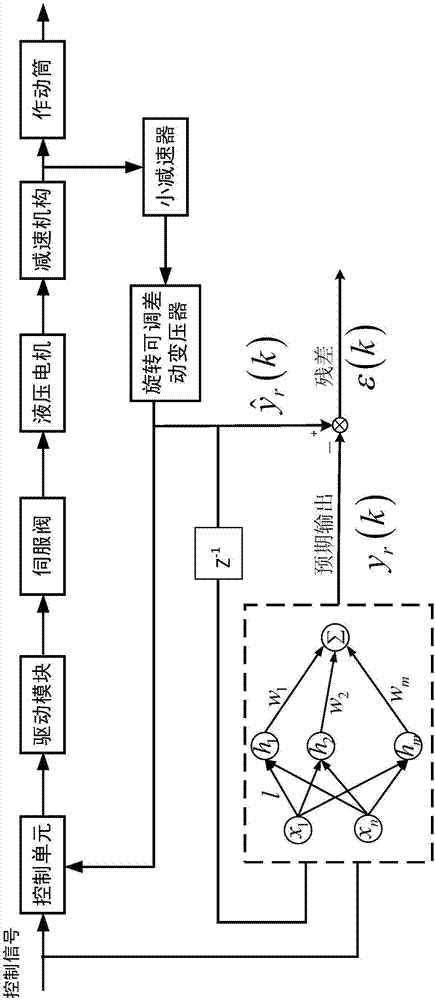

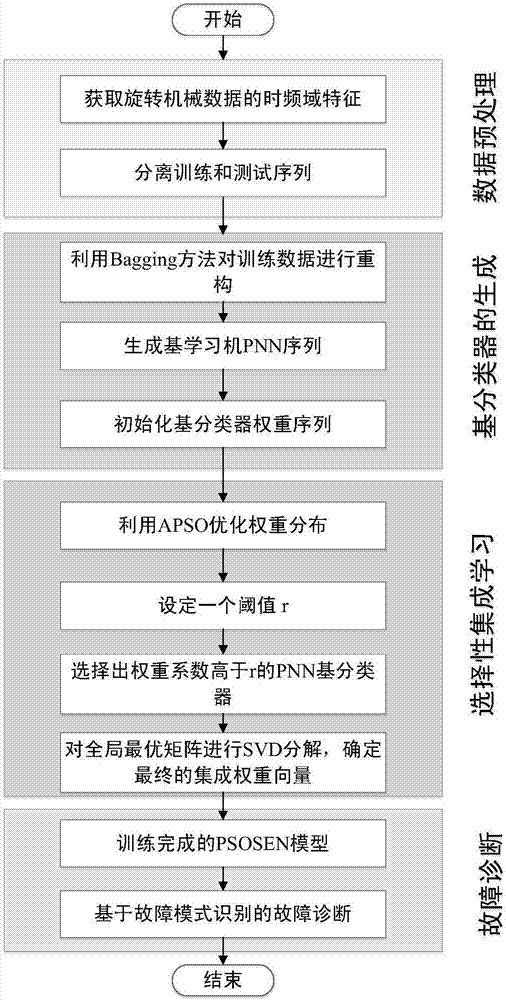

Selective integrated learning-based rotating machinery fault diagnosis method

An integrated learning and fault diagnosis technology, applied in neural learning methods, complex mathematical operations, computer components, etc., can solve problems such as data complexity of rotating machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] 1. Generation of base classifier

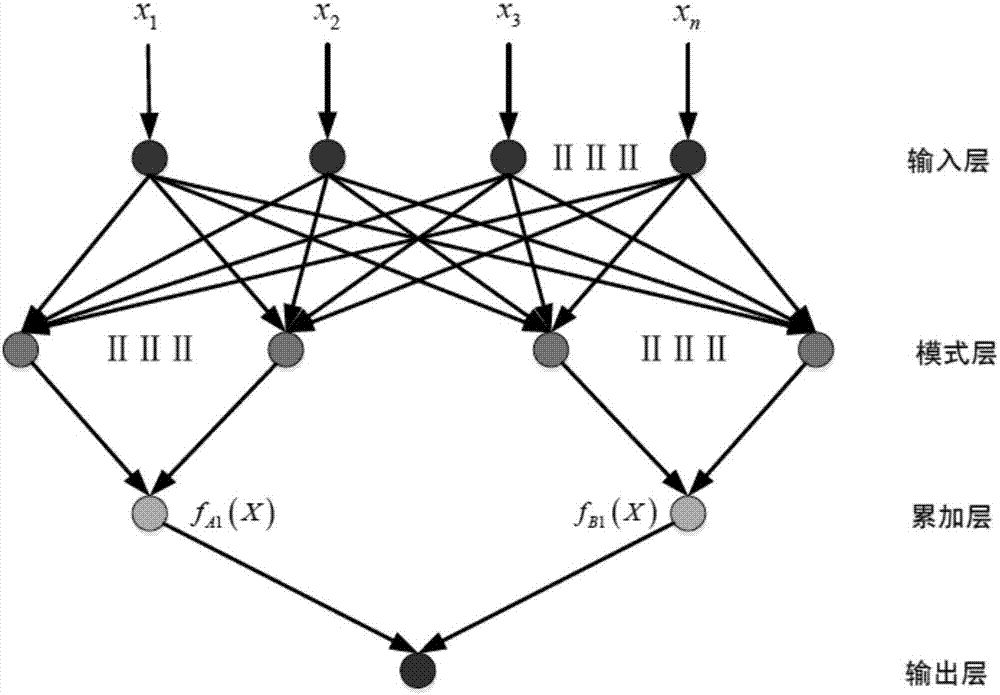

[0044]The present invention adopts probabilistic neural networks (PNN) as a base classifier to realize the recognition of the fault mode of the rotating machinery. PNN is a forward neural network based on Bayesian minimum risk criterion and nuclear Fisher discriminant, which was invented by D.F.Specht in 1990. Usually, the PNN network structure is as figure 1 shown.

[0045] exist figure 1 In, we can find that the PNN network can usually be divided into four layers: the input layer, the model layer, the accumulation layer and the output layer. When a test input signal is given to the network, the input layer will first calculate the distance between the data point in the signal and the training vector point; then, the pattern layer will use a radial basis function to convert the distance into Corresponding weight parameters; in the overlay layer, the weight parameters of each point in the input data for different failure modes will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com