Forage processing peculiar smell treatment method and equipment

A feed processing and odor treatment technology, applied in gas treatment, separation methods, dispersed particle separation, etc., can solve the problems of high operating costs, complicated management operations, and complicated processing, and achieve operating cost savings, engineering investment savings, and strong market. The effect of competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

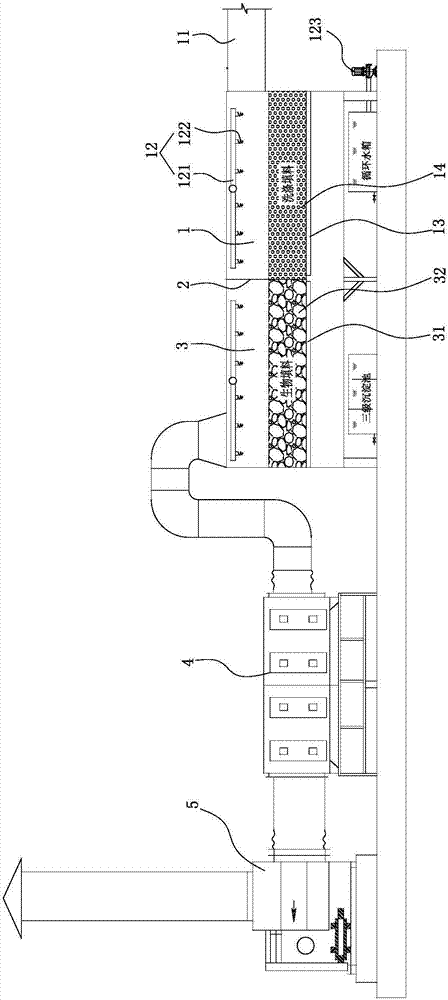

[0023] See figure 1 As shown, it is a feed processing odor treatment equipment, which includes: a pre-wash tank 1, a biological filter tank 3, a UV photolysis device 4 and a rear suction fan 5 connected in sequence.

[0024] The pre-wash pool 1 acts as an effective buffer to reduce the peak of high-concentration pollution load. The pre-wash tank 1 is provided with an air intake main pipeline 11, and the pre-wash tank 1 is equipped with a horizontal circulation spray humidification system 12; specifically, the horizontal circulation spray humidification system 12 includes a The circulation pipeline 121 in the pre-wash tank 1 and several spray heads 122 evenly installed on the circulation pipeline 121 and the circulation water pump 123 connected with the circulation pipeline 121, the circulation water pump 123 is arranged outside the pre-wash tank 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com