Method for controlling pass-line deflection of finishing mill stand according to intermediate billet camber

A technology of camber bending and finishing mill, applied in the direction of profile control, rolling force/roll gap control, etc., can solve the problems affecting the stability of finishing rolling, achieve low synchronization and real-time performance, low cost, reduce The effect of finish rolling deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1-A2

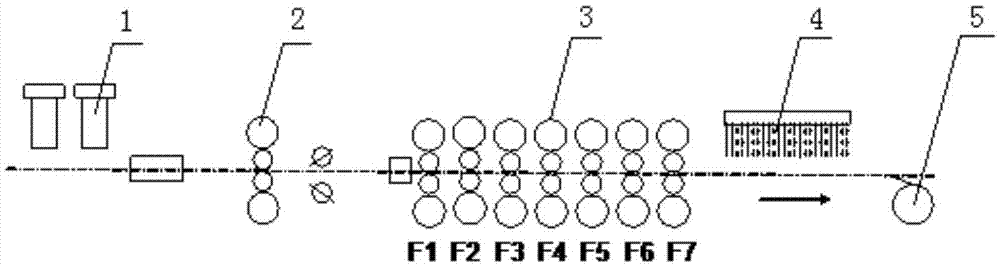

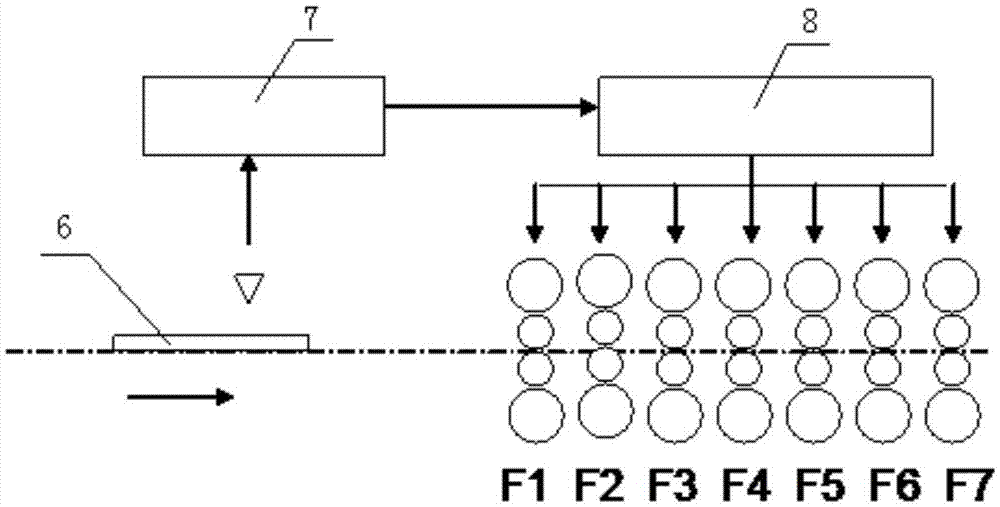

[0038] image 3 The control system used in the method of controlling the deviation of the finish rolling stand according to the camber of the intermediate billet according to the embodiment A1-A2 is illustrated, Figure 4 The flow of the method for controlling the deviation of the finish rolling stand according to the camber of the intermediate slab in the embodiments A1-A2 is illustrated.

[0039] Such as image 3 As shown, the control system used in the method of controlling the deviation of the finishing stand according to the camber of the intermediate slab in the embodiment A1-A2 includes a width meter 7 and an industrial control computer 8, and the industrial control computer 8 cooperates with the width meter 7 and the finishing stand The pressing control system of F1-F7 is realized.

[0040] Such as Figure 4 shown, combined with reference image 3 , the specific steps of the method for controlling the deviation of the finish rolling stand according to the camber of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com