Extruding-punching forging die for hub unit

A wheel hub unit and punching technology, which is applied in the direction of manufacturing tools, wheels, forging/pressing/hammer devices, etc., can solve the problems of long processing hours, high production costs, and low utilization rate of forging materials, so as to reduce the use of molds, Scientific structure and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

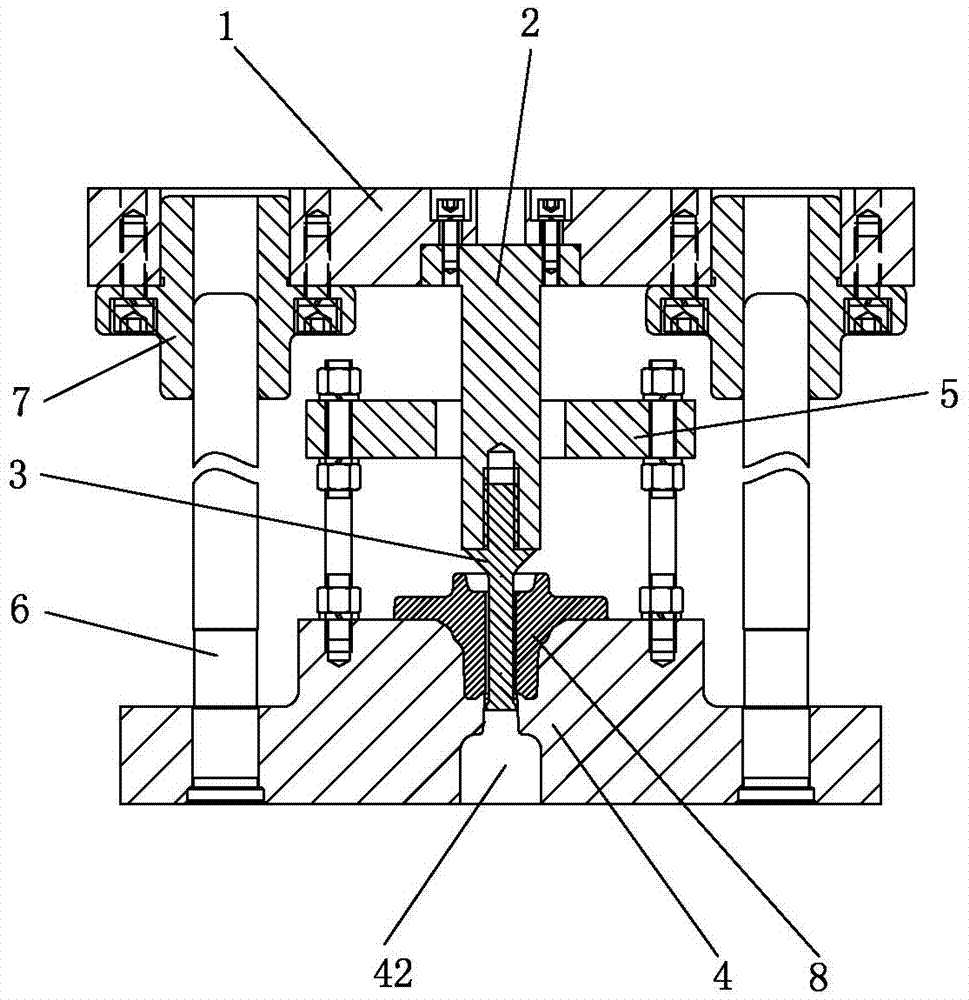

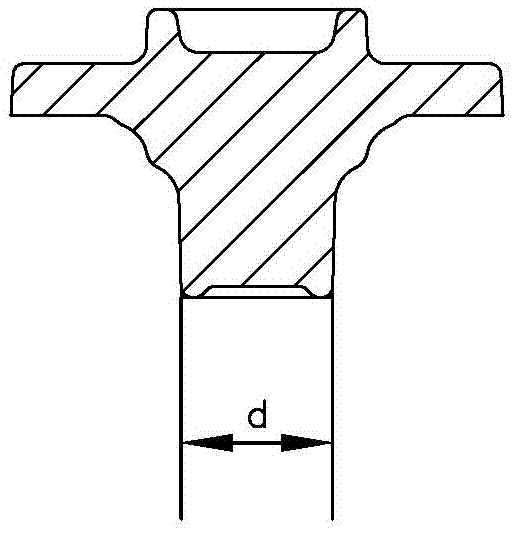

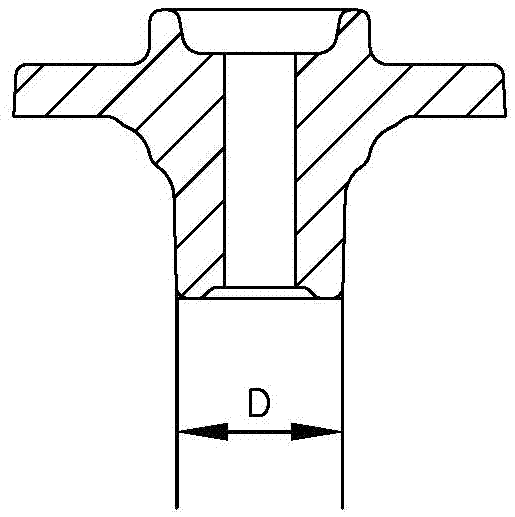

[0026] Such as figure 1 , Figure 4 , Figure 5 As shown, the wheel hub unit extrusion punching forging die of this embodiment includes an upper die and a lower die, and the upper die includes an upper die seat 1, a punch seat 2, and a punch 3, and the punch seat 2 is fixed on the upper die Seat 1, the upper end of punch 3 is fixed in punch seat 2 by screw thread, and described lower die comprises punch 4, stripping plate 5 (lower die can also comprise lower die seat, in the present embodiment, punch 4 and The lower mold base is integrated), the punch 4 is provided with a mold cavity 41 for accommodating the cylindrical end of the hub unit, the bottom of the mold cavity 41 is provided with a downwardly penetrating ejection hole 42, and the mold cavity 41 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com