Swing arm middle-arranged-type double-axle steering system

A steering system, center-mounted technology, applied in the direction of steering mechanism, steering rod, transportation and packaging, etc., can solve the problems of small front wheel rotation angle, complex structure, large space occupation, etc., and achieve large output torque and strong adaptability of wheelbase , the effect of taking up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

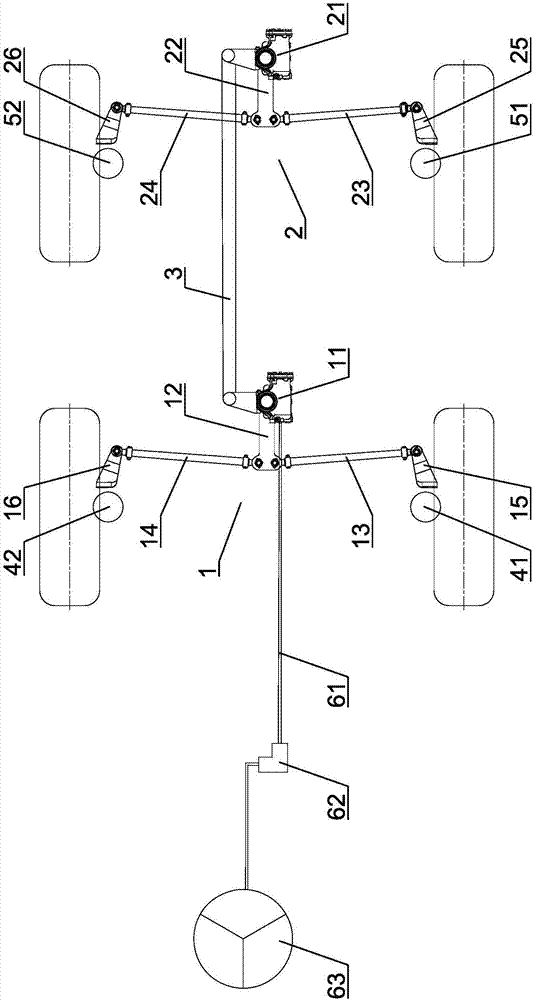

[0011] Such as figure 1 Shown is a specific embodiment of a swing arm mid-mounted double-axle steering system of the present invention, which includes a front axle steering unit 1 , a rear axle steering unit 2 and a trailing rod 3 . The front axle steering unit 1 specifically includes a power steering gear 11 , a front axle swing arm 12 , a front axle left tie rod 13 , a front axle right tie rod 14 , a front axle left trapezoidal arm 15 and a front axle right trapezoidal arm 16 . The rear axle steering unit 2 specifically includes a follower 21 , a rear axle swing arm 22 , a rear axle left tie rod 23 , a rear axle right tie rod 24 , a rear axle left trapezoidal arm 25 and a rear axle right trapezoidal arm 26 . The power steering 11 and the follower 21 are spaced apart in the front-rear direction and an oil passage is provided therebetween. Let the front axle swing arm 12 and the rear axle swing arm 22 both adopt an L-shaped structure and be arranged at intervals along the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com