Block precuring conveying system based on PLC and conveying method thereof

A conveying system and block technology, applied in conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of manual handling, time-consuming and laborious, manual arrangement of mold cars, etc., to reduce cost input and change operation. effect of the way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

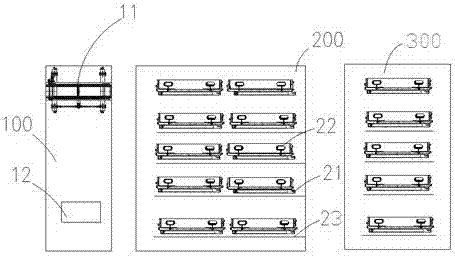

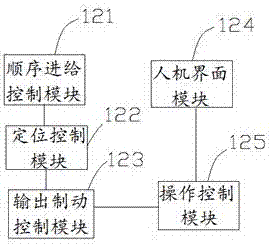

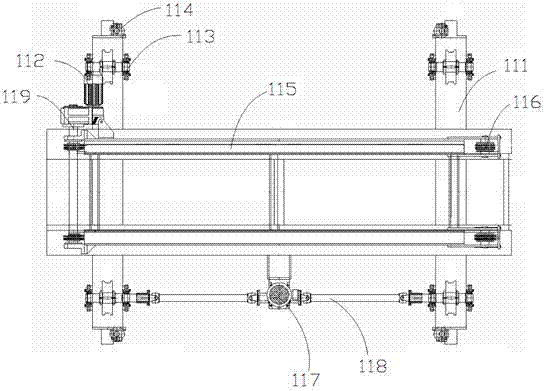

[0032] This embodiment provides a PLC-based block pre-cultivation conveying system, such as Figure 1-2 As shown, it is used to transport the mold car 22 from the batching building 100 to the preset track line 23 inside the pre-curing room 200. The pre-curing delivery system includes: PLC controller 12, controlled by the PLC controller 12, The ferry car 11 located in the batching building 100, the ferry car 11 includes a horizontal formwork 115, a longitudinal formwork 111, and a conveyor chain 21 preset according to the preset track line 23, the PLC controller 12 includes a sequential feed control module 121, a positioning control module 122, an output braking control module 123, a man-machine interface module 124, and an operation control module 125,

[0033] The sequential feeding control module 121 is used to control the feeding movement and the sequence of the movement when the shuttle car 11 drives each mold car 22 into the pre-curing room 200;

[0034] The positioning ...

Embodiment 2

[0047] The second embodiment provides a PLC-based block pre-curing transportation method, which is used to transport the mold car 22 from the batching building 100 to the preset track line 23 inside the pre-curing room 200 through the ferry car 11, including:

[0048] Pre-set work instructions, and output execution instructions according to the work instructions;

[0049] According to the execution order, control the shuttle car 11 to drive each mold car 22 to enter the feeding motion and the sequence of motion when the mold car 22 enters the pre-curing room 200;

[0050] Control the direction of movement and the size of the movement displacement of the ferry car 11, and control the shuttle car 11 to transport the mold car 22 to the preset track line 23 for pre-cultivation;

[0051] After pre-curing is finished, control the ferry car 11 to drive each mold car 22 to be transported to the bottom of the spreader and then brake, and be transported to the cutting line by the spread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com