Steel pipe longitudinal defect magnetic leakage detection device based on rotary magnetizing field

A technology of rotating magnetization and longitudinal defects, applied in the direction of material magnetic variation, etc., can solve the problems of high cost, low practicability, uneven magnetization, etc., and achieve the effect of low maintenance cost, simple structure and compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

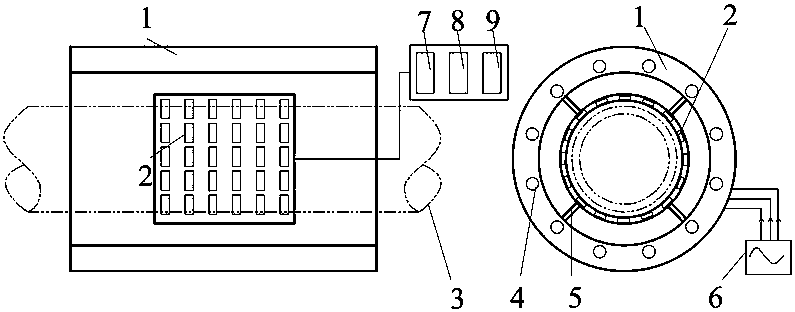

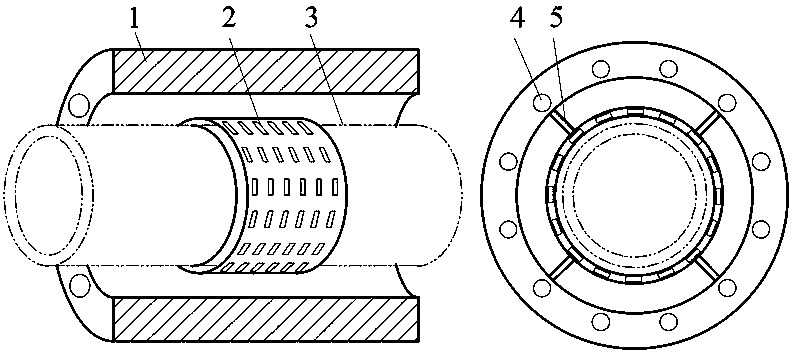

[0024] The specific embodiments of the present invention are given below in conjunction with the accompanying drawings, and the magnetic flux leakage flaw detection device for steel pipe longitudinal defects based on the rotating magnetization field of the present invention will be further described through the specific embodiments. It should be pointed out that the specific implementation of the present invention is not limited to the forms described in the examples.

[0025] The directional terms mentioned in the detailed description below, such as: up, down, left, right, front, back, etc., are only directions referring to the drawings. Therefore, the directional terms used are only for the convenience of explaining the present invention, and are not intended to limit the present invention.

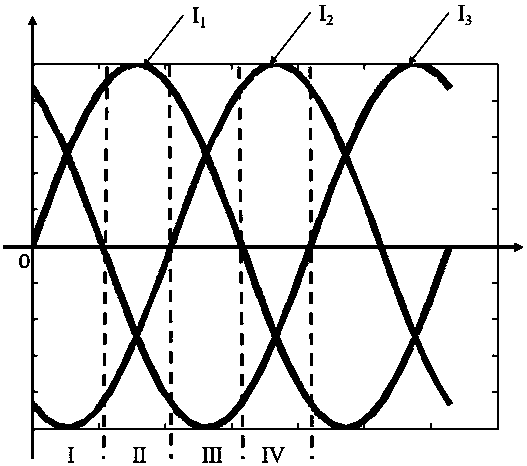

[0026] The magnetic flux leakage flaw detection device for longitudinal defects of steel pipes based on the rotating magnetization field in this embodiment has a schematic structural di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com