Fault injection method and system

A fault injection and fault technology, applied in the field of computer simulation, can solve problems such as unsatisfactory, unapproachable evolution environment development, complex time-space change characteristics of evolution, and difficulty in effective control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

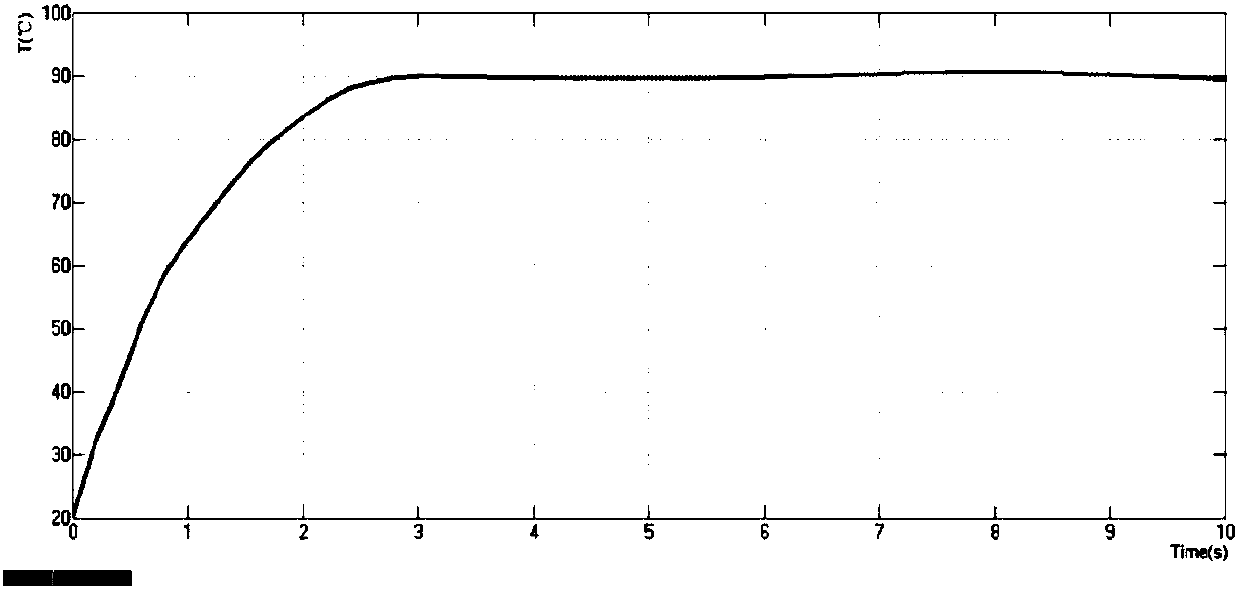

[0066] In this embodiment, a fault simulation is performed on the evolution process of the performance degradation of the power device of the rectifier circuit in the traction converter until an open-circuit fault occurs. This embodiment is performed in the virtual simulation platform Simulink software environment, and the environment defines that "0" and "1" signals represent the off and on states of the power device, respectively.

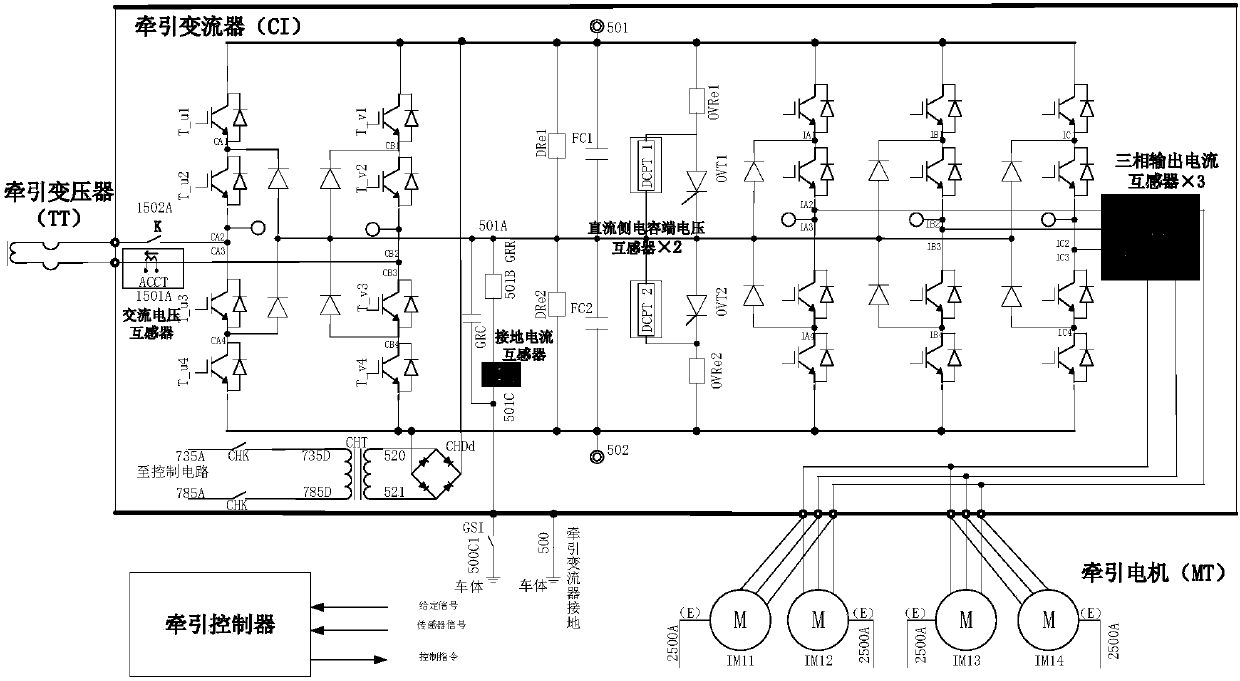

[0067] figure 1 It is a schematic diagram of the traction system of the CRH2 type high-speed train adopted in this embodiment. By receiving sensor signals and command signals, the traction controller calculates the conduction state of each power device in the converter according to the preset control algorithm, so as to realize the control of the running state of the traction system of the high-speed train; the traction converter is responsible for receiving the contact The high-voltage power grid is converted into low-voltage single-phase power...

Embodiment 2

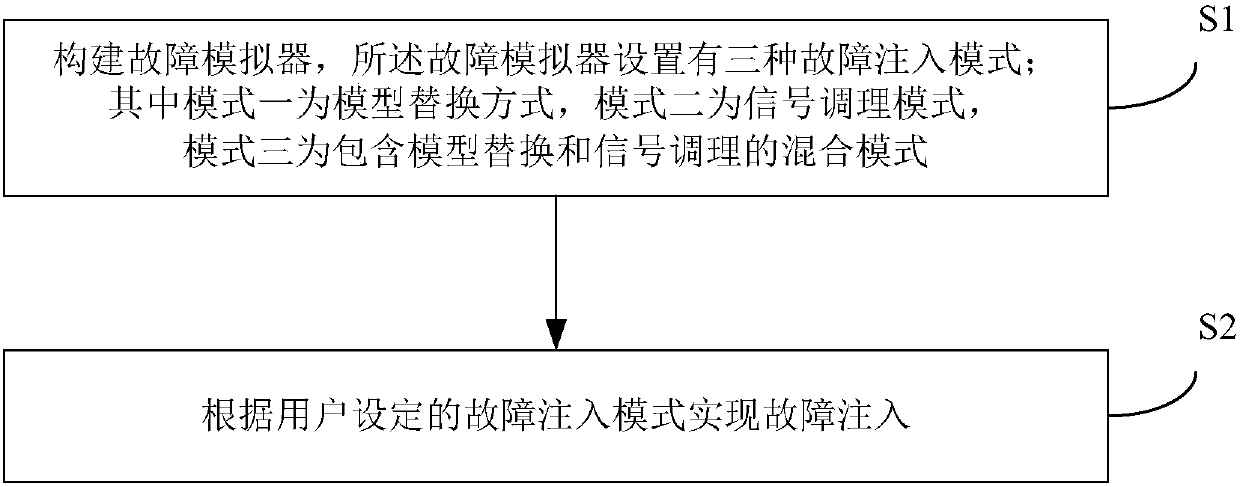

[0142] Corresponding to the above embodiments, the present embodiment discloses a fault injection system including a fault simulator. The fault simulator is provided with three fault injection modes; the first mode is a model replacement mode, the second mode is a signal conditioning mode, and the mode The third is a mixed mode including model replacement and signal conditioning; it is used to implement fault injection according to the fault injection mode set by the user. The fault injection system can be applied to simulate the fault injection of the traction drive system of high-speed trains. The corresponding fault source is composed of five parts: the traction controller, the traction transformer, the traction converter, the traction motor and the on-board sensor in the traction drive system of the high-speed train. .

[0143] like Figure 11 As shown, the fault simulator constructed in this embodiment includes a fault injection controller, and the fault injection contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com