High-voltage direct-current transmission valve cooling system's working condition prediction and fault heads-up platform

A cooling system, high-voltage direct current technology, used in transportation and packaging, instruments, simulators, etc., can solve problems such as technical specifications for the cooling system of the converter valve that are not involved, so as to speed up the processing speed, reduce hidden dangers, and reduce the occurrence of failures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

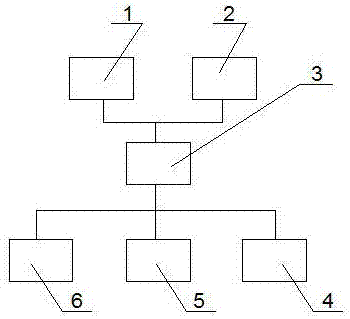

[0041] A high-voltage direct current transmission valve cooling system operating condition prediction and fault early warning platform, including a data processing module 1, a data exchange module 3 that is signal-connected to the data processing module 1, and the data exchange module 3 is also connected to a teacher for teaching Working module 2, student training module 4 for learning, printing module 5 for printing results, and simulation mechanism 6 for simulating data.

[0042] In this embodiment, the historical data of the converter valve is collected through the working condition mechanism, and the records and evaluations are carried out, and it is used as the simulation data of the simulation mechanism to input and judge whether the data of the simulation mechanism is accurate; and the test method includes data processing Module, and the data processing module that the present invention adopts is the cloud computing of centralized processing data or the server that can s...

Embodiment 2

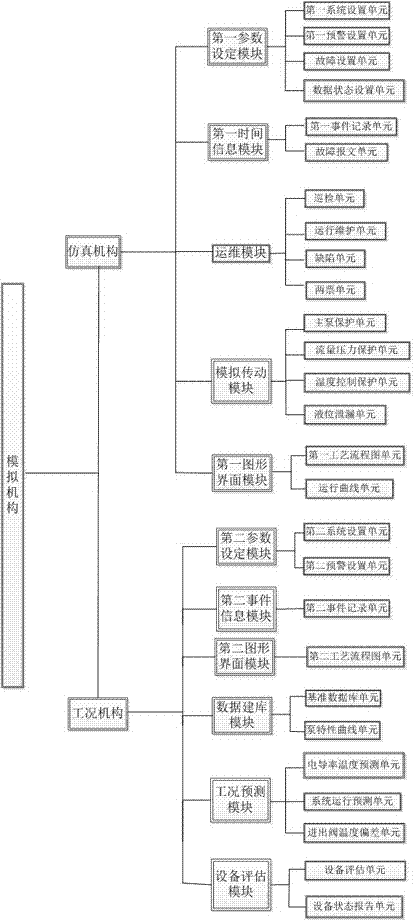

[0044] It differs from Embodiment 1 in that: the simulation mechanism includes a simulation mechanism and a working condition mechanism;

[0045] The simulation mechanism includes a first parameter setting module, a first event information module, an operation and maintenance module, a simulated transmission module and a first graphical interface module;

[0046] The working condition mechanism includes a second parameter setting module, a second event information module, a second graphic interface module, a data database building module, a working condition prediction module and an equipment evaluation module.

[0047] The simulation mechanism used in this embodiment includes a simulation mechanism and a working condition mechanism. The simulation mechanism can analyze the data of the working condition mechanism, and virtualize a fault situation for the students to solve, and will pass the whole process data to the instructor's work The module allows the teacher to directly o...

Embodiment 3

[0050] The difference from Embodiment 2 is that the first parameter setting module has a first system setting unit, a first warning setting unit, a fault setting unit and a data state setting unit;

[0051] The first event information module includes a first event recording unit and a fault message unit;

[0052] The operation and maintenance module includes an inspection unit, an operation and maintenance unit, a defect unit and a two-ticket unit;

[0053] The analog transmission module includes a main pump protection unit, a flow pressure protection unit, a temperature control protection unit and a liquid level leakage unit.

[0054] The first graphical interface module includes a first process flow chart unit and a running curve unit.

[0055] The operation and maintenance module used in this embodiment is an important function of the simulation training platform for the converter valve cooling system to train the trainees on switching operations. When the simulation trai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com