Treatment method of electroplating sludge

A technology of electroplating sludge and treatment methods, which is applied in sludge treatment, fixed/solidified sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of high cost and large energy consumption, and reduce waste and reduce Bulk volume, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

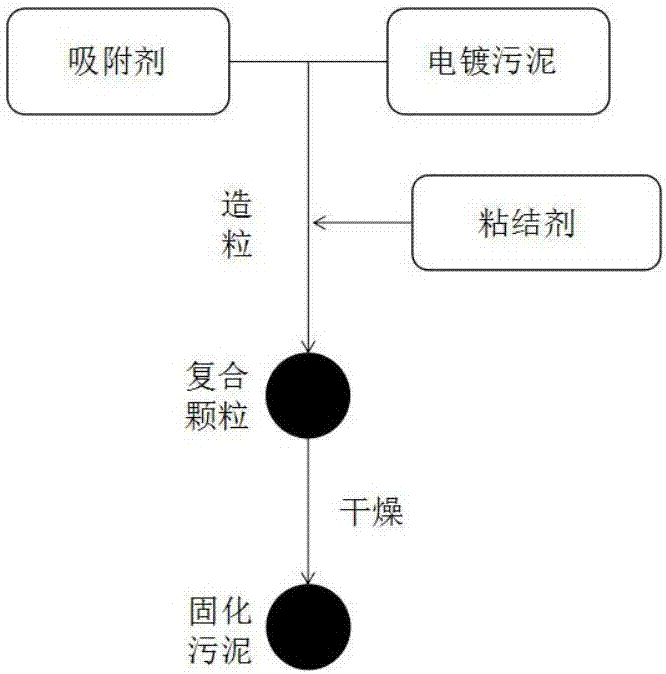

[0023] combined with figure 1 , embodiment 1, the treatment method of a kind of electroplating sludge of the present invention, described preparation method comprises the steps:

[0024] (1) Dissolve polyvinyl alcohol particles in hot water at 95°C to obtain a PVA solution, and cool it naturally for use;

[0025] (2) Take the electroplating sludge and the mineral powder used as the solidified adsorbent, put them in a granulator for mixing and stirring, and at the same time spray an appropriate amount of the PVA aqueous solution prepared in step (1), and stir for 2-30 minutes to form composite electroplating sludge particles;

[0026] (3) Dry the composite electroplating sludge particles obtained in step (2) at 80-120° C. for 6-12 hours to obtain the electroplating sludge / mineral powder composite material.

[0027] A method for treating electroplating sludge, in step (1), the concentration of the PVA solution is 5-15wt.%.

[0028] A method for treating electroplating sludge. ...

Embodiment 2

[0035] Embodiment 2, a kind of treatment method of electroplating sludge, take by weighing 600g drying electroplating sludge and 400g bentonite mix, place in the granulator and stir, spray 400ml 5wt.% PVA aqueous solution simultaneously, open the granulator, make After granulation for 15 minutes, the bonded electroplating sludge composite particles were taken out and placed in an oven at 80°C for 6 hours to obtain composite electroplating sludge particles.

Embodiment 3

[0036] Example 3 A treatment method for electroplating sludge, weighing 600g of oven-dried electroplating sludge and mixing it with 300g of zeolite, placing it in a granulator for stirring, spraying 200ml of 8wt.% PVA aqueous solution at the same time, opening the granulator, and granulating The bonded electroplating sludge composite particles were taken out after 5 minutes and dried in an oven at 100°C for 12 hours to obtain composite electroplating sludge particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com