Crystal cotton lycra net fabric and production technology thereof

A cotton stretcher net and production process technology, applied in yarn, application, clothing and other directions, can solve the problems of poor ventilation effect, loose structure of body-shaping underwear fabric, poor moisturizing and sweat-absorbing performance, etc., and achieve the effect of ensuring physiological health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

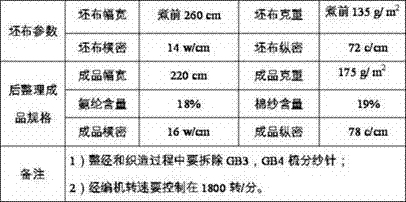

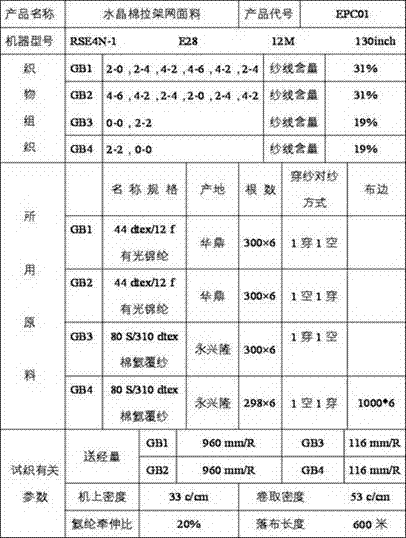

[0021] In embodiment 1, a kind of crystal cotton stretch net fabric is made of following mass percentage components: 19% cotton, 18% spandex and 63% nylon, the main component of this fabric front is nylon, and the main component of reverse side is Spandex covered yarn.

Embodiment 2

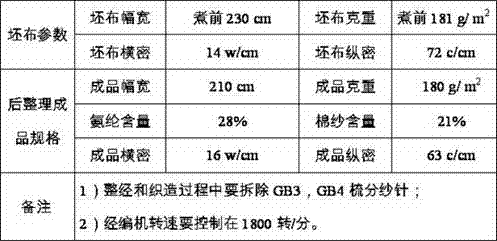

[0022] In embodiment 2, a kind of crystal cotton frame net fabric is made of the following mass percentage components: 21% cotton, 28% spandex and 51% nylon, the main component of this fabric front is nylon, and the main component of the back is Spandex covered yarn.

[0023] The production process of the fabric is as follows:

[0024] Raw material inspection→yarn loading (placed at constant temperature)→warping→spinning→yarn threading→weaving→cloth falling, weighing→grain cloth storage→washing→pre-setting→dyeing→final setting (finishing)→finished product inspection→rolling, Weighing, packaging → finished product storage

[0025] During the yarn feeding process, it is necessary to reduce the difference between the pulling-out distance of the bobbin and the bending degree of the yarn, and ensure that the yarn path is short, which is conducive to ensuring that the tension of the whole yarn is highly consistent. During the yarn loading process of nylon, after shaking the creel,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com