Slurry circulation system of slurry balance shield and slurry balance shield

A mud-water balance and circulation system technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems affecting the mud-water balance shield construction efficiency, ground collapse in front of the cutterhead, and inability to dredge the mud door, so as to prevent landmark settlement or uplift phenomenon, reduce slurry pressure, prevent surface subsidence or uplift effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

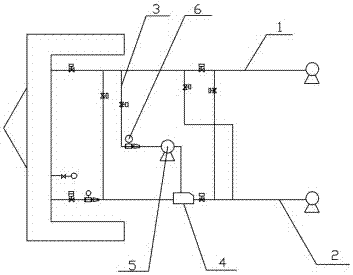

[0028] join figure 1 , a mud-water balance shield mud circulation system, including a slurry inlet pipe 1 and a slurry discharge pipeline 2, and also includes a The slurry return circulation pipeline 3 of the slurry discharge pipeline 2, a flow divider 4 is set at the connection between the slurry return circulation pipeline 3 and the slurry discharge pipeline 2 to facilitate the smooth return of the slurry to the return circulation pipeline 1 Inside, a booster pump 5 is arranged on the mud return pipeline, and the first end of the slurry inlet pipeline and the second end of the slurry discharge pipeline of the booster pump 5 are respectively provided with valves.

[0029] The booster pump 5 is a centrifugal pump, which is used for pumping and discharging mud and pressurizing pipelines, which can increase the slurry feeding pressure, increase the slurry feeding flow rate, enhance the slag-carrying capacity of the slurry, and further enhance the excavation chamber 8. Increased...

Embodiment 2

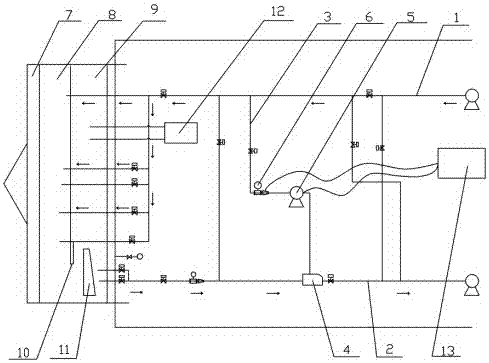

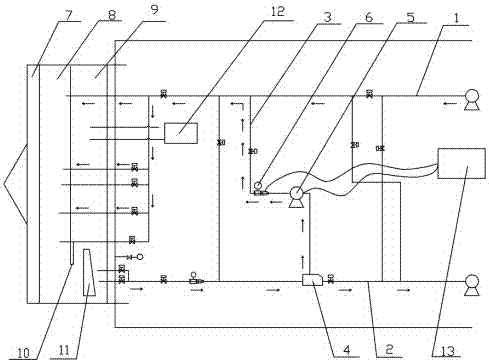

[0032] join figure 2 , a mud-water balance shield, comprising a cutter head 7, an excavation chamber 8, an air cushion chamber 9, a mud door 10, a stone crushing device 11, a gas pressure maintaining device 12, an excavation chamber pressure detection device, an electric control system 13 and a mud Circulation system, wherein the mud circulation system includes a slurry inlet pipeline 1, a slurry discharge pipeline 2 and a mud return pipeline 3, and the mud return circulation pipeline 3 is arranged between the slurry inlet pipeline 1 and the slurry discharge pipe The slurry inlet pipeline 1 and the slurry discharge pipeline 2 are connected between the pipelines 2, and a flow divider 4 is set between the slurry return circulation pipeline 3 and the slurry discharge pipeline 2 to facilitate the smooth return of the slurry to the slurry discharge pipeline. In the circulation pipeline 1, a booster pump 5 is arranged on the mud return pipeline 3, and valves are respectively set at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com