Resin-coated metal sheet for can ends

A technology for metal plates and can ends, applied in the field of resin-coated metal plates for can ends, to achieve excellent seaming resistance and excellent content resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, one embodiment of the present invention will be described in detail with reference to the drawings. In addition, this invention is not limited by this embodiment.

[0035]

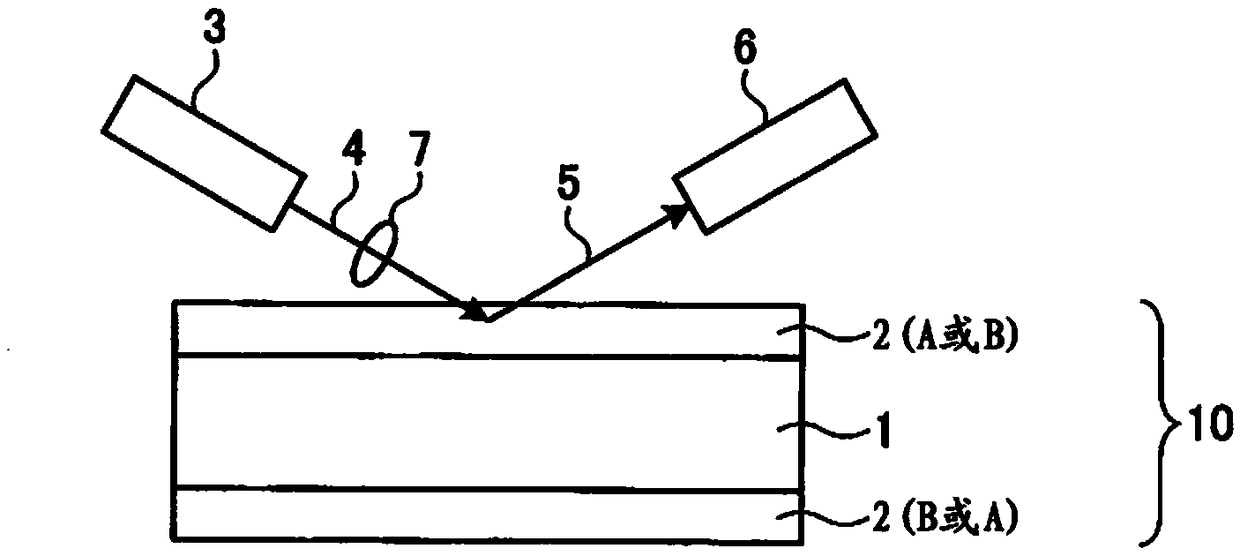

[0036] First, refer to figure 1 , the measurement method of the laser Raman spectroscopy used in the present invention will be described. Such as figure 1 As shown, for a resin-coated metal plate 10 in which a resin film 2 is laminated on both sides of a metal plate 1, laser light 4 oscillated by a laser oscillator 3 is incident on the resin film 2 on one side, and is scattered by a beam splitter 6. The Raman scattered light 5 is split. In the laser Raman spectroscopy, the beam diameter of the laser light 4 irradiated is variable by the lens 7, and the crystallinity of a region of a necessary size can be evaluated. Furthermore, by reducing the beam diameter of the laser beam 4 to be irradiated, it is possible to evaluate the degree of crystallinity of the minute domain of the resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com