Liquid crystal element with negative dielectric anisotropy

A technology for liquid crystal elements and liquid crystal compositions, applied in liquid crystal materials, nonlinear optics, instruments, etc., can solve the problems of low reliability of measurement results, insufficient display quality, and reduced VHR value, so as to improve display quality and reduce residual orders. effect of bulk, high voltage retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0172] Example 1 satisfies the physical property values required for liquid crystal televisions, and the values of VHR (after polymerization treatment) and ID (after polymerization treatment) are good. On the other hand, the liquid crystal composition of Comparative Example 1 has a large γ1 and is considered to have a long response time. The residual monomer ratio after polymerization treatment was also large, and the values of VHR (after polymerization treatment) and ID (after polymerization treatment) were inferior to those of Example 1. As can be seen from the above, Example 1, which is a liquid crystal element of the present invention, satisfies various characteristics required by liquid crystal televisions, has a sufficiently small residual monomer ratio, and is excellent in reliability, and is very useful as a long-life active matrix type liquid crystal display element. .

[0173] Furthermore, Table 3 shows the liquid crystal compositions and device physical prope...

Embodiment 2

[0176] Example 2 satisfies the physical property values required for liquid crystal televisions, and the values of VHR (after polymerization treatment) and ID (after polymerization treatment) are good. On the other hand, the liquid crystal composition of Comparative Example 1 has a large γ1 and is considered to have a longer response time. The residual monomer ratio after polymerization treatment was also large, and the values of VHR (after polymerization treatment) and ID (after polymerization treatment) were inferior to those of Example 2. As can be seen from the above, Example 2, which is a liquid crystal element of the present invention, satisfies various characteristics required by liquid crystal televisions, has a sufficiently small residual monomer ratio, and is excellent in reliability, and is very useful as a long-life active matrix type liquid crystal display element. .

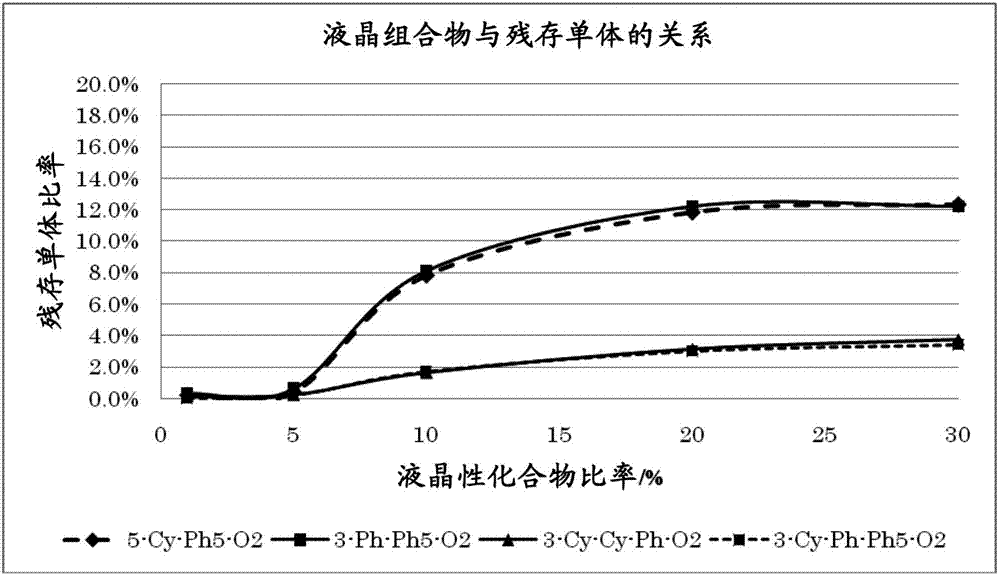

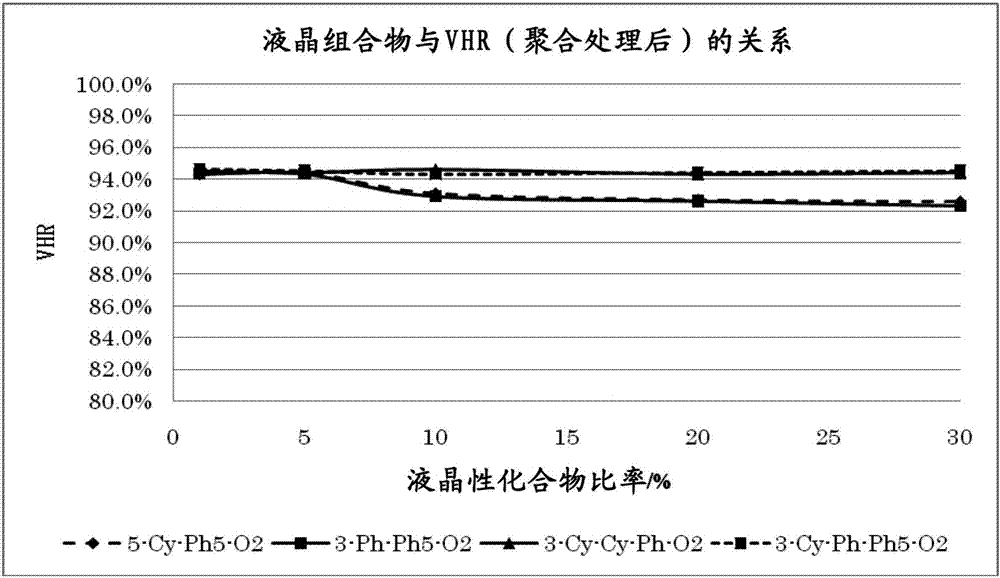

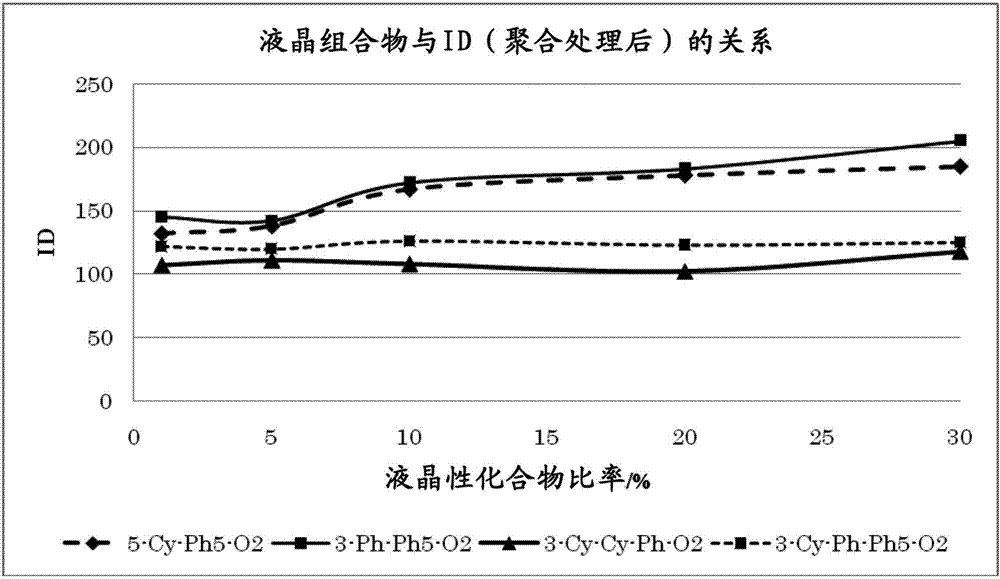

[0177] Furthermore, in order to confirm the relationship between the liquid crystal compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com