Anisotropic conductive film and connection structure

一种各向异性、导电性膜的技术,应用在导电连接、电部件连接、连接等方向,能够解决连接电阻偏差等问题,达到确保导通、抑制制造成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0103] Examples 1-4, Comparative Example 1

[0104] (1) Manufacture of anisotropic conductive film for FOG connection

[0105] The preparation includes 60 parts of phenoxy resin (thermoplastic resin) (Nippon Steel (Steel) Sumikin Co., Ltd., YP-50), 40 parts of epoxy resin (thermosetting resin) (Mitsubishi Chemical Co., Ltd., jER828), A mixed solution of 2 parts of cationic curing agent (Sanshin Chemical Industry Co., Ltd., SI-60L) of insulating resin is coated on a PET film with a film thickness of 50 μm, dried in an oven at 80°C for 5 minutes, and placed in a An adhesive layer with a thickness of 20 μm was formed on the PET film.

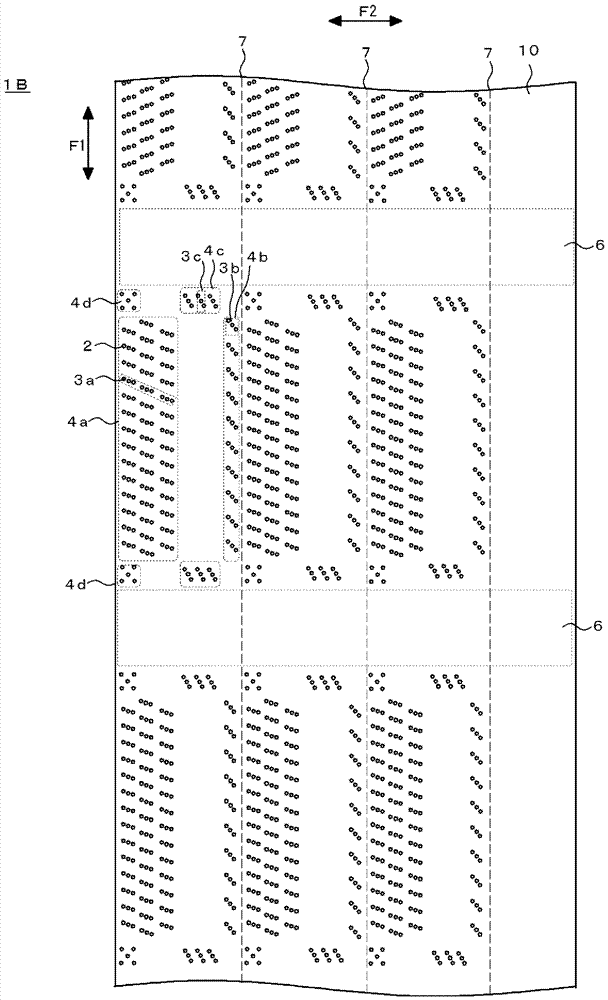

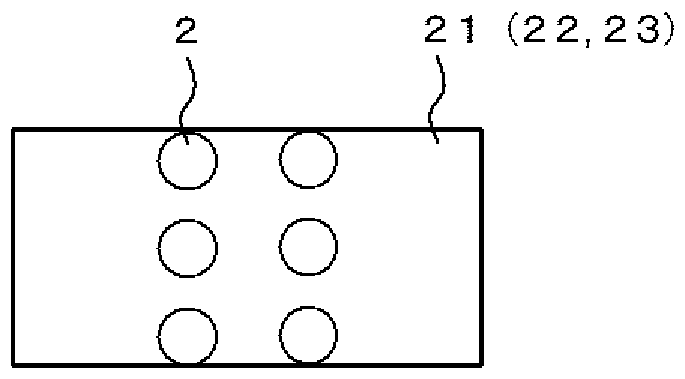

[0106] On the other hand, according to the arrangement of the electrode terminals of the FOG-connected substrate, a mold in which the protrusions periodically have an arrangement pattern with a predetermined arrangement density (Examples 1 to 4) or a mold in which the protrusions are randomly arranged with a predetermined arrangement density (Comp...

Embodiment 5~9、 comparative example 2

[0132] (1) Manufacture of anisotropic conductive film for COG connection

[0133] In the same manner as in Example 1, 60 parts of phenoxy resin (thermoplastic resin) (Nippon Steel & Sumitomo Metal Co., Ltd., YP-50) and epoxy resin (thermosetting resin) (Mitsubishi Chemical Co., Ltd., jER828) were used. 40 parts and 2 parts of cationic curing agent (Sanshin Chemical Industry Co., Ltd., SI-60L) were used to form an adhesive layer with a thickness of 20 μm on the PET film.

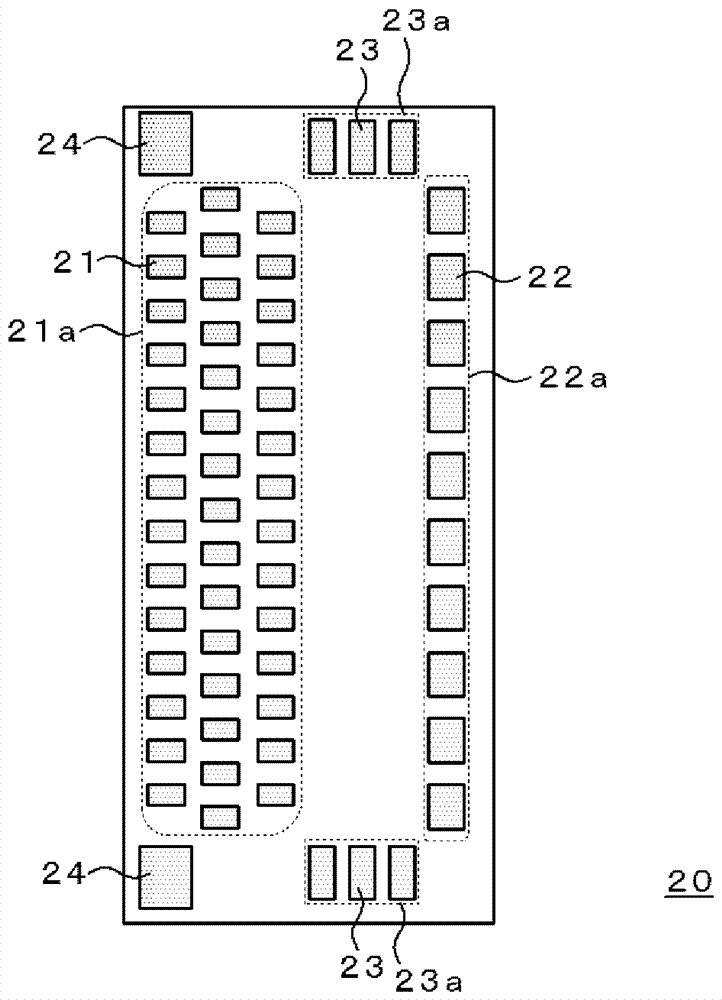

[0134] On the other hand, according to the bump arrangement of the IC chip connected by COG, a mold with an arrangement pattern in which the protrusions periodically have a predetermined arrangement density (Examples 5 to 9) or a 4-square grid of protrusions (grid pitch 8 μm) was produced. The mold (comparative example 2) was poured into the mold in the state where the particles of the known transparent resin were melted, cooled and solidified, and a resin mold in which the recesses were in a lattice pattern ...

Embodiment 10~14

[0160] In Examples 5 to 9, 20 parts of quartz filler (quartz particles, AEROSIL RY200, Japan AEROSIL Co., Ltd.) were added to 100 parts of insulating resin, and anisotropic conductive films were produced in the same manner as in Examples 5 to 9, and Continuity evaluation was performed. The results were all good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com