Powder moistening machine and peach slice powder moistening machine

A technology of peach slices and rollers, applied in the field of peach slicer and peach slicer, can solve the problems of caking, affecting the quality of peach slices, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

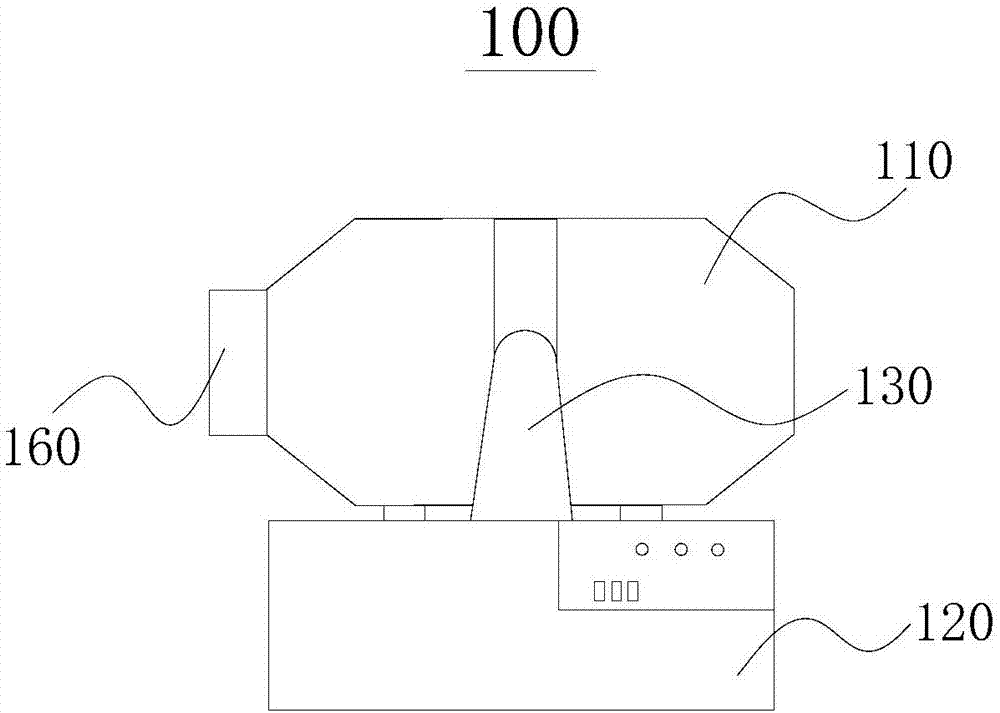

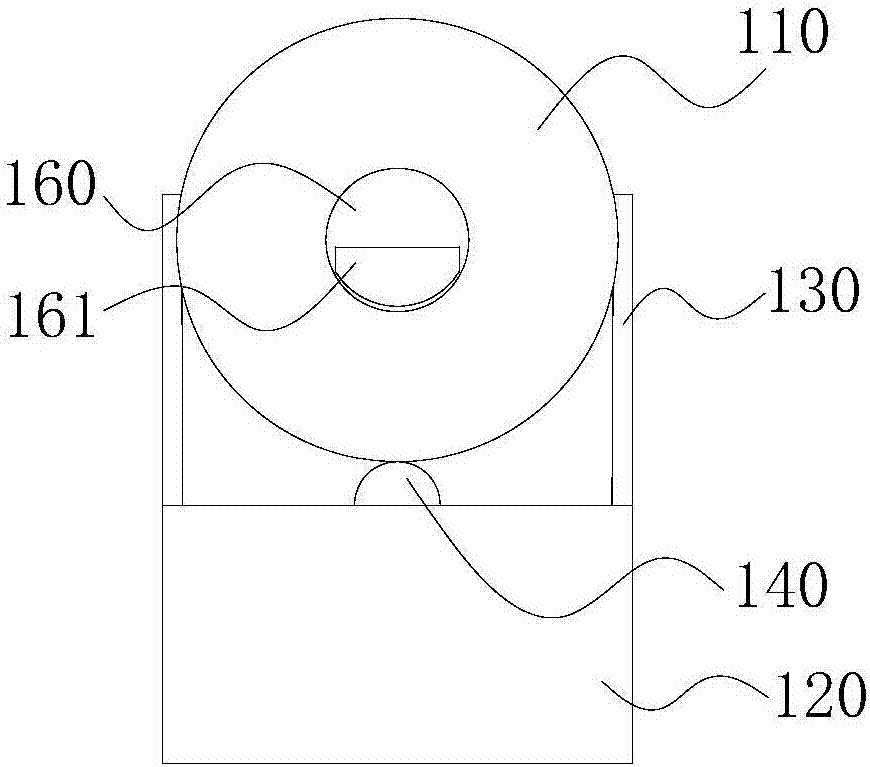

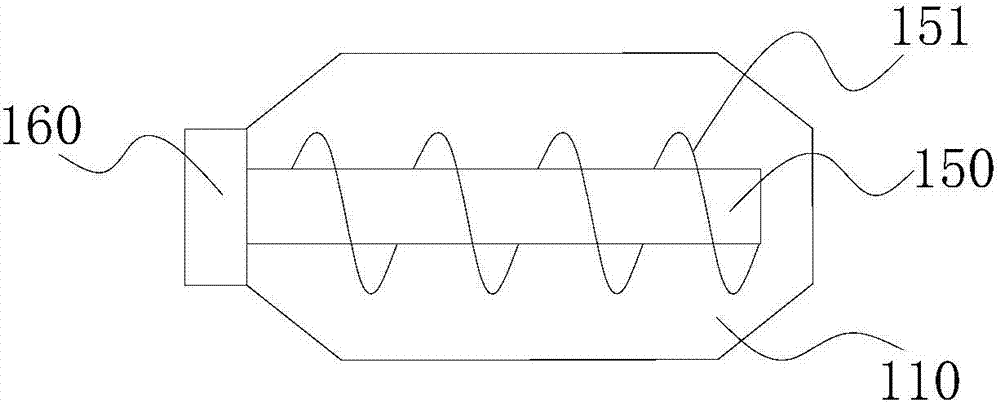

[0045] refer to figure 1 , the figure shows a powder moistening machine 100 provided in this embodiment. Moisturizing powder machine 100 comprises cylinder 110, base 120, support 130, motor (not marked among the figures), stirring device and figure 2 Drive wheel 140 visible in .

[0046] Also refer to figure 1 and figure 2 , the motor is located in the base 120, and the driving wheel 140 is connected with the motor. The bracket 130 is fixedly connected to the base 120 , and the roller 110 is slidably and rotatably connected to the bracket 130 . The driving wheel 140 is rotatably connected with the outer peripheral surface of the drum 110 . The motor drives the driving wheel 140 to rotate, and when the driving wheel 140 rotates, the drum 110 is driven to rotate around its axis. The outer peripheral surface of the drum 110 is slidably and rotatably connected to the bracket 130 for supporting the drum 110 and controlling the pitch of the drum 110 to facilitate discharging...

Embodiment 2

[0056] refer to Figure 4 , the figure shows a peach slice moistening machine 200 provided by this embodiment, similar to Embodiment 1, which includes a drum 110, a base 120, a bracket 130, a motor, a driving wheel 140 and a stirring device.

[0057] The motor is arranged in the base 120, and the driving wheel 140 is connected with the motor. The bracket 130 is fixedly connected to the base 120 , and the roller 110 is slidably and rotatably connected to the bracket 130 . The driving wheel 140 is rotatably connected with the outer peripheral surface of the drum 110 . The motor drives the driving wheel 140 to rotate, and when the driving wheel 140 rotates, the drum 110 is driven to rotate around its axis. The outer peripheral surface of the drum 110 is slidably and rotatably connected to the bracket 130 for supporting the drum 110 and controlling the pitch of the drum 110 to facilitate discharging materials from the drum 110 or adding materials to the drum 110 .

[0058] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com