Technological structure of integrated evaporation tower capable of acquiring clean steam in energy-efficient manner

A pure steam and evaporation tower technology, applied in the field of evaporation towers, can solve the problems of incomplete gas-liquid separation such as material entrainment, low purity of secondary steam, and high evaporation efficiency, and achieve wide adaptability to working conditions, small volume, and high evaporation efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

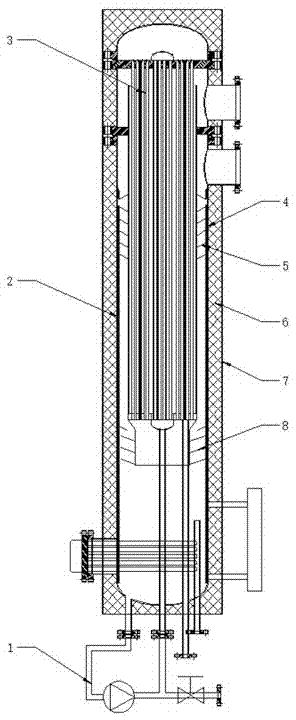

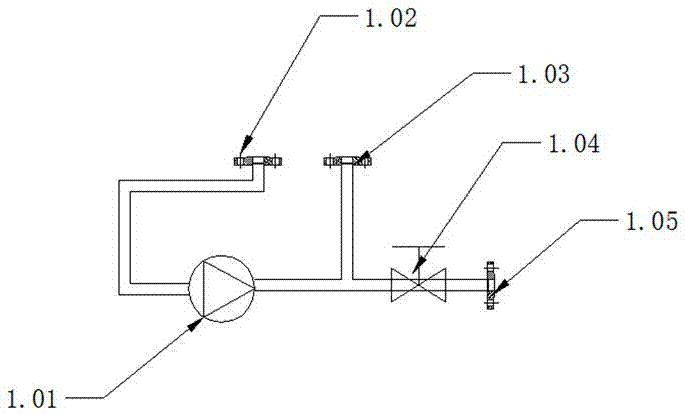

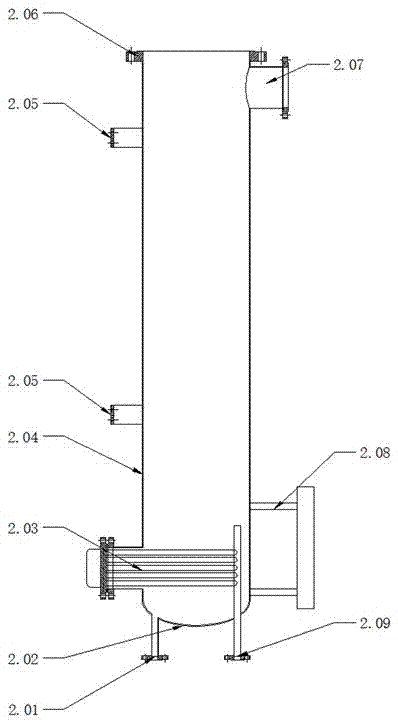

[0019] see figure 1 , figure 2 , image 3 , Figure 4 , the present invention provides a technical solution: a process structure of an integrated evaporation tower capable of energy-saving and efficient acquisition of pure steam, including a forced circulation system 1, a gas-liquid separation structure shell 2, an evaporation structure 3, a jacket 4, and a steam spiral centrifuge Purifier 5, insulation 6, shell 7, spiral centrifuge demister 8.

[0020] The material enters the bottom of the evaporation tower from the feed port 2.01 and is heated by the heating unit 2.03 and is close to the boiling point. It is pumped into the tube 3.07 in the evaporation structure 3 through the forced circulation pump 1.01. After the secondary heating of the heating steam entering the heating steam inlet 3.16, the material is Over the boiling point, under a certain pressure state, evenly spread in the flange head 3.12 of the tower body through the upper head 3.13 of the feed at the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com