A kind of high modulus oil corrosion resistant asphalt mixture and preparation method thereof

A technology of asphalt mixture and high modulus, which is applied in the field of road building materials to achieve great economic and social benefits, prolong service life, and avoid early damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

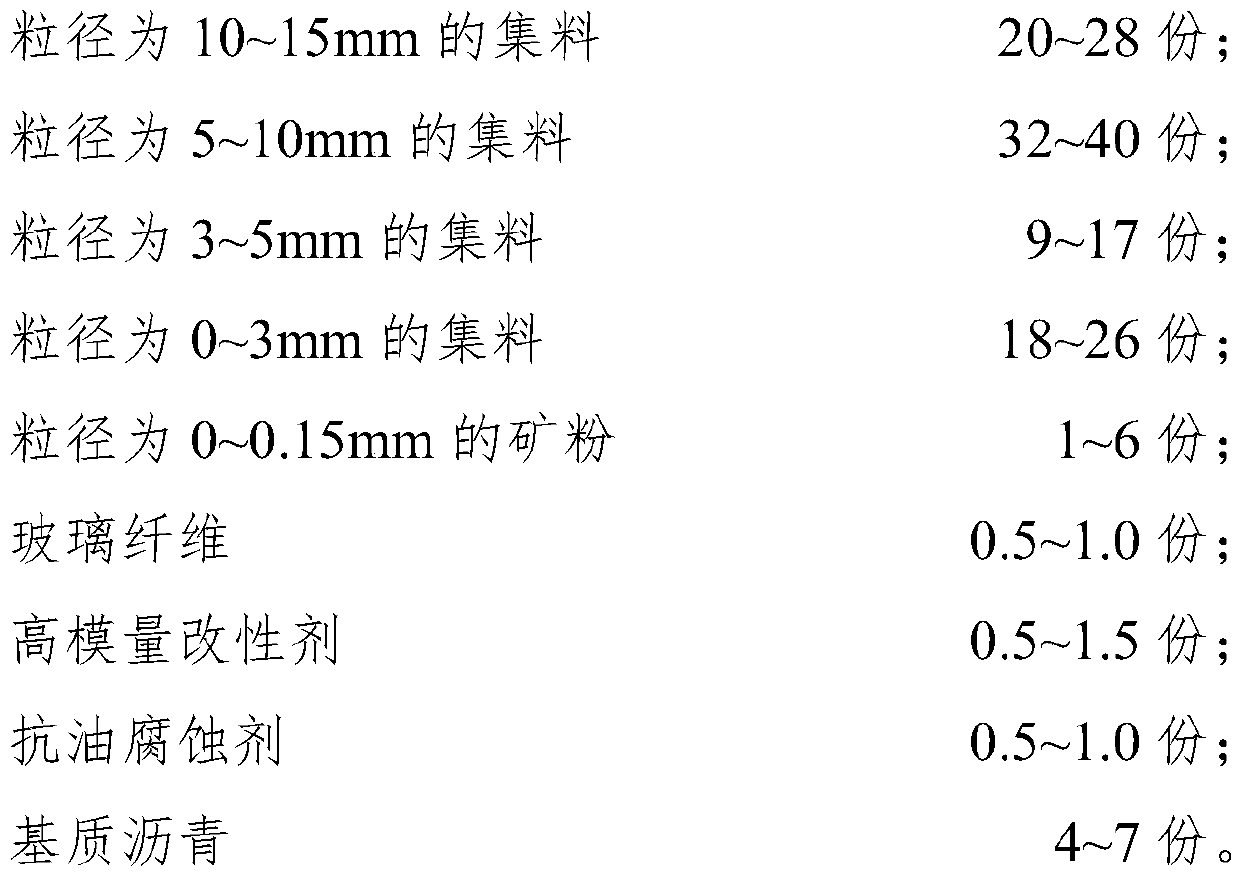

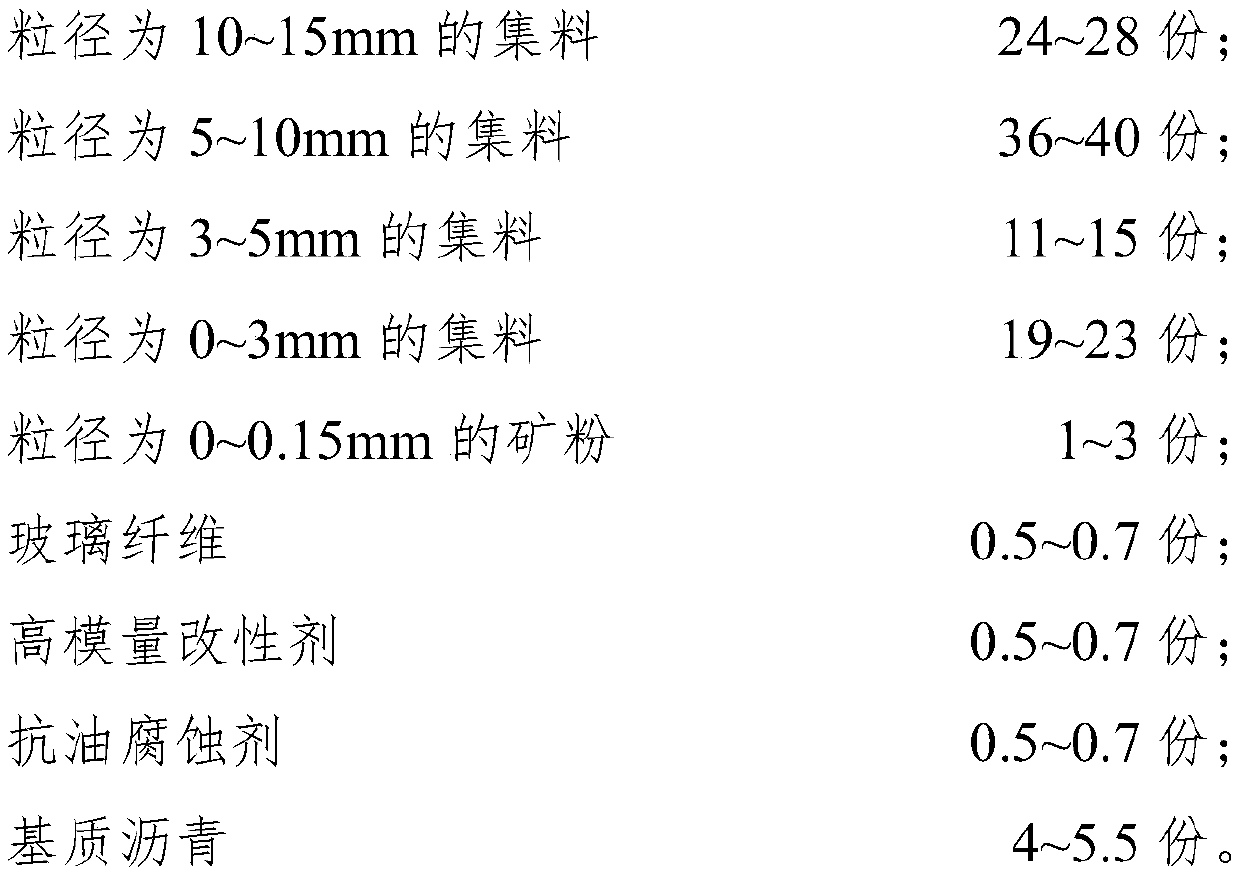

Method used

Image

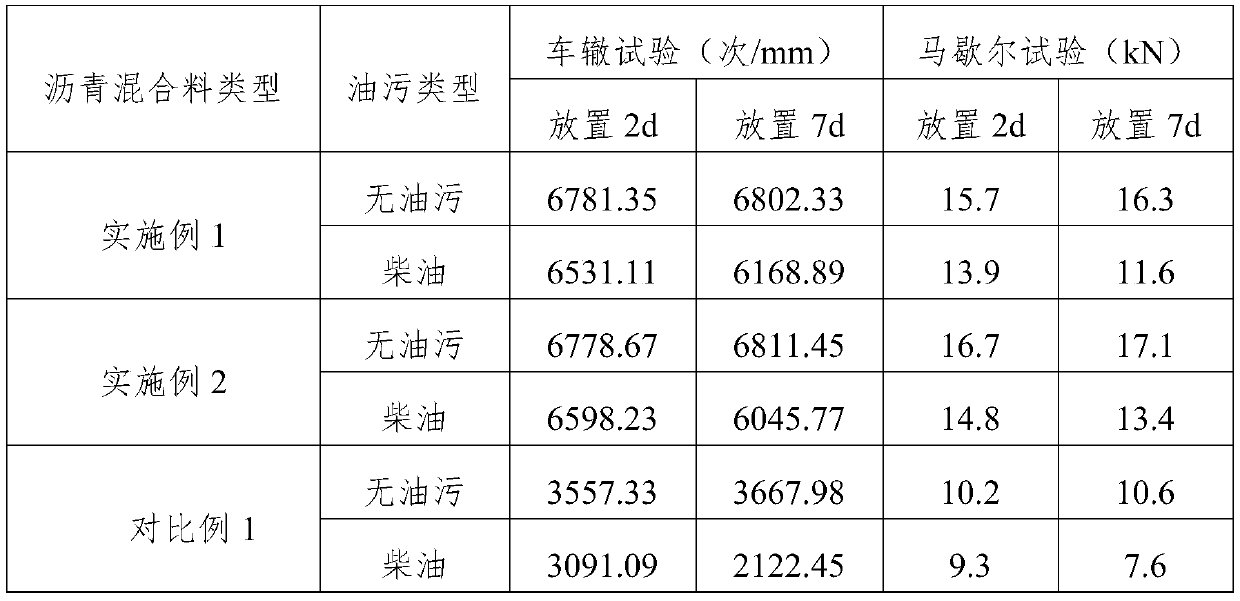

Examples

Embodiment 1

[0029] This embodiment provides a high modulus oil corrosion resistant asphalt mixture, which is composed of: 26 kg of limestone aggregates with a particle size of 10 to 15 mm, 38 kg of limestone aggregates with a particle size of 5 to 10 mm, and limestone with a particle size of 3 to 5 mm 13kg of aggregate, 21kg of limestone aggregate with a particle size of 0-3mm, 2kg of mineral powder with a particle size of 0-0.15mm, 0.5kg of high modulus modifier, 0.5kg of polyether modified polysiloxane, and 0.5kg of glass fiber , base asphalt 4.8kg.

[0030] Wherein, the high modulus modifier is composed of a modified matrix and additional light stabilizers, compatibilizers, antioxidants and oxidized polyethylene added to the modified matrix; in practical applications, each After the ingredients are mixed, a twin-screw extruder is used to melt and granulate to obtain a high modulus modifier;

[0031] in particular:

[0032] The modified matrix is formed by mixing LLDPE, LDPE and SBS...

Embodiment 2

[0038] This embodiment provides a high-modulus oil-resistant asphalt mixture. Compared with Embodiment 1, the only difference is that the modified matrix is formed by mixing LLDPE, LDPE and SBS at a mass ratio of 6.5:2:1.5. become.

Embodiment 3

[0040] This example provides a method for preparing a high-modulus oil-resistant asphalt mixture. The mixture described in Examples 1 and 2 can be prepared by this method, specifically:

[0041] (1) Add the aggregate, mineral powder and glass fiber to the agitator, and directly put the high modulus modifier and the anti-oil corrosion agent into the agitator during the dry mixing process, and mix evenly;

[0042] (2) Add base asphalt to the mixture obtained in step (1), and stir evenly to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com