White spirit vinasse organic fertilizer as well as preparation method and application thereof

A technology of liquor lees and organic fertilizer, which is applied in the field of preparation of lees organic fertilizer, can solve the problems of incomplete decomposition of lees, incomplete decomposing, waste of manpower, material resources, financial resources and time, etc., so as to prevent secondary pollution, corruption and soil alkalinity. effect of improving yield and quality, protecting the environment and soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

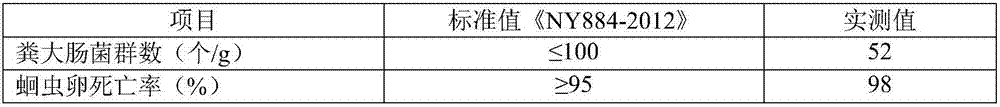

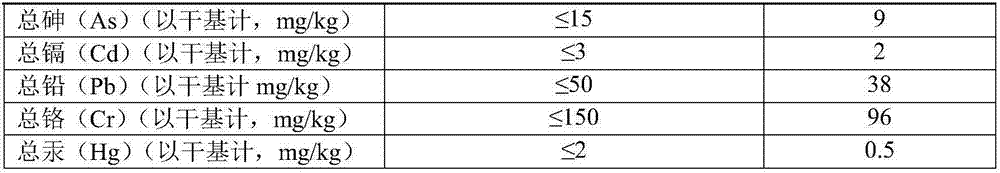

[0052] A preparation method of liquor distiller's grain organic fertilizer, comprising the following steps: uniformly mixing fresh liquor distiller's grains and distiller's grain decomposing agent according to the mass ratio of 1.2:1000, forming a heap, and composting and fermenting; fermenting for 24 hours, the temperature of the heap reaching 55°C and continuing Raise the temperature, turn the compost once at this time, continue composting and fermentation, and then turn the compost once a day; ferment for 72 hours, the temperature of the heap body reaches 85°C, enters the high-temperature fermentation period, no longer turn the pile, and maintain fermentation at 83-85°C for 72 hours. At this time, the temperature of the compost begins to drop, enters the post-fermentation period, and continues to ferment for 240 hours. The temperature of the compost reaches 32°C. After cooling for 24 hours, the liquor distiller's grain organic fertilizer is obtained.

[0053] The pH value o...

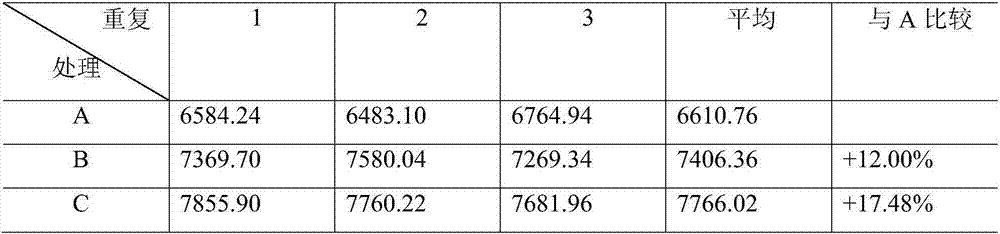

Embodiment 2

[0073] A preparation method of liquor distiller's grain organic fertilizer, comprising the following steps: uniformly mixing fresh liquor distiller's grains and distiller's grain decomposing agent at a mass ratio of 1:1000, forming a heap, and composting and fermenting; fermenting for 22 hours, the temperature of the heap reaching 55°C and continuing Raise the temperature, turn the compost once at this time, continue composting and fermentation, and then turn the compost once a day; after 70 hours of fermentation, the temperature of the heap body reaches 85°C, entering the high-temperature fermentation period, no more turning over the pile, and maintaining fermentation at 83-85°C for 72 hours. At this time, the temperature of the compost begins to drop, enters the post-fermentation period, and continues to ferment for 220 hours. The temperature of the compost reaches 32°C. The distiller's grains are completely decomposed. The fermentation ends. The fermented compost is crushed, ...

Embodiment 3

[0088] A preparation method of liquor distiller's grain organic fertilizer, comprising the following steps: uniformly mixing fresh liquor distiller's grains and distiller's grain decomposing agent according to the mass ratio of 1.5:1000, forming a heap, and composting and fermenting; fermenting for 26 hours, the temperature of the heap reaching 55°C and continuing Raise the temperature, turn the compost once at this time, continue composting and fermentation, and then turn the compost once a day; ferment for 74 hours, the temperature of the heap body reaches 85°C, enters the high-temperature fermentation period, no longer turns the pile, and maintains fermentation at 83-85°C for 72 hours. At this time, the temperature of the compost begins to drop, enters the post-fermentation period, and continues to ferment for 230 hours. The temperature of the compost reaches 32°C, and the distiller's grains are completely decomposed. The fermentation ends. The fermented compost is crushed, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com