System and method for steelmaking sludge sintering slaking

A technology for steel-making sludge and sludge, applied in the direction of manufacturing converters, etc., can solve the problems of a large amount of operating capital, long turnaround time, and high technical requirements, and achieve the effects of reducing recycling costs, reducing process failure rates, and fast switching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are examples of the present invention, which are only used to explain the present invention and not limit it.

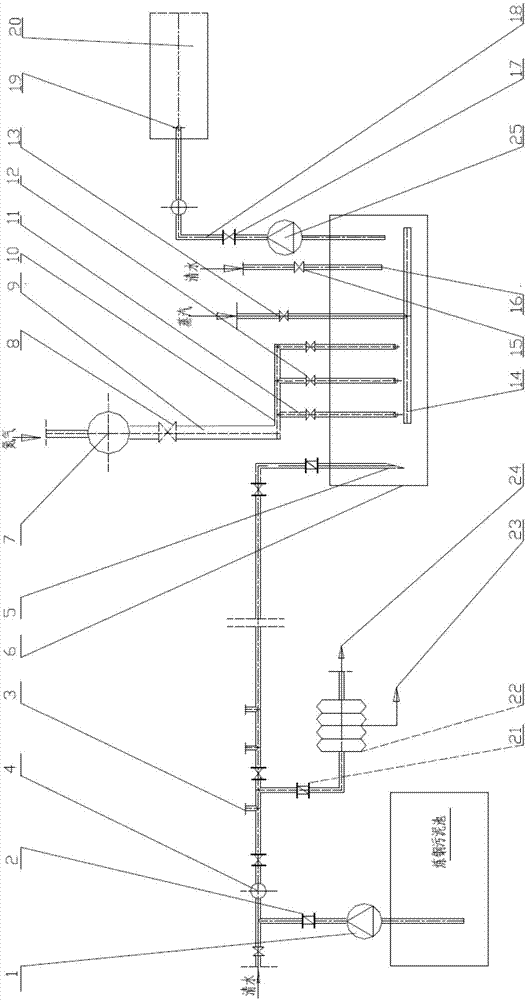

[0029] see figure 1 , the system for sintering and digesting steelmaking sludge provided by the present invention typically includes a sludge direct pipeline and a sintering sludge pretreatment pool 6, wherein:

[0030] A steelmaking sludge water pump 1 is installed on the sludge direct transportation pipeline, and the sludge direct transportation pipeline is connected to a sintered sludge pretreatment pool 6, and a heating pipeline 14 is arranged in the sintered sludge pretreatment pool 6 , compressed gas pipeline and sludge sintering pipeline 18, the sintered sludge pump 25 is arranged on the sludge sintering pipeline 18, and the sintered sludge pipeline 18 is also connected with the sintered sludge nozzle 19; the compression Gas pipeline and compressed gas source connection;

[0031] The steelmaking sludge enters the sintered sludge pretreat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com