A controllable aluminum electrolytic cell anode covering sealing system and an aluminum electrolytic cell for its application

An aluminum electrolytic cell and anode covering technology, applied in the field of aluminum electrolytic cells, can solve problems such as difficulty in flue gas preheating, low efficiency of flue gas collection, and deterioration of workshop work, achieving continuous, stable and efficient production, streamlining the structure of production equipment, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

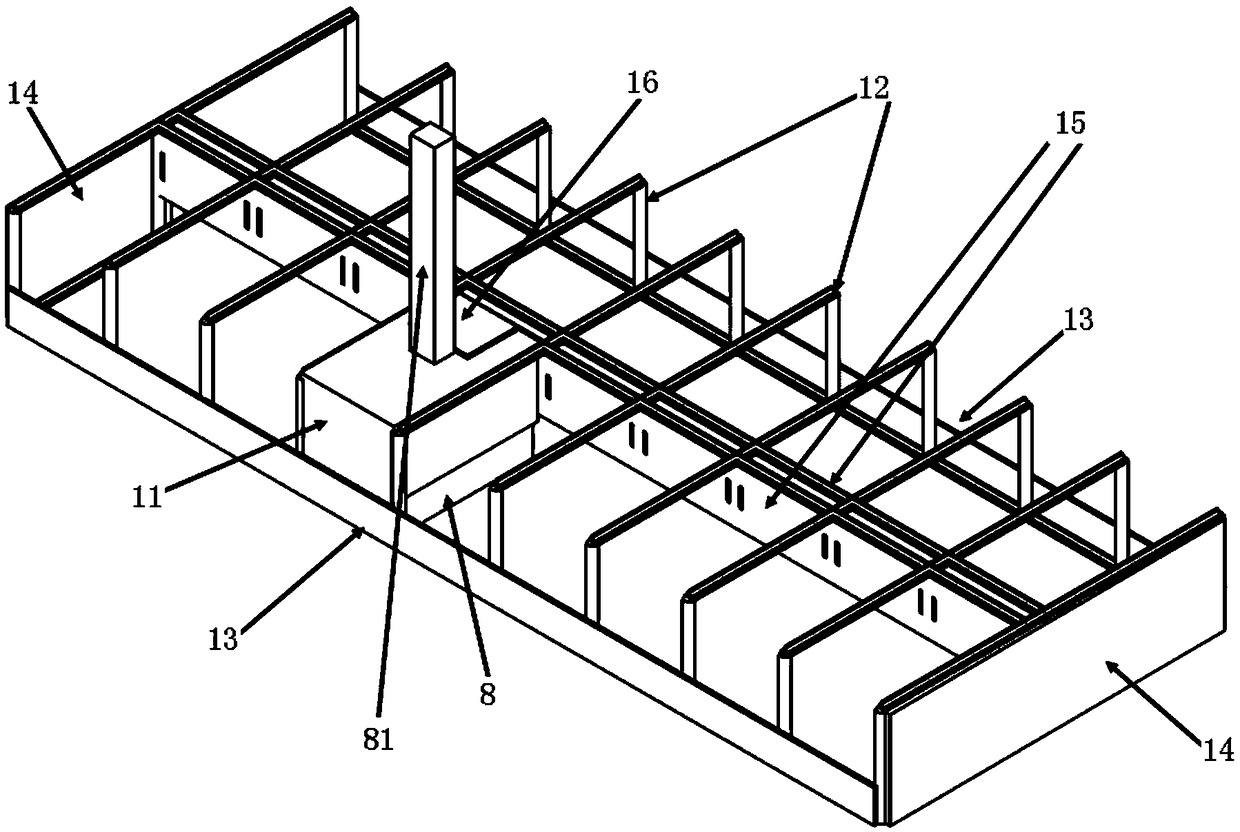

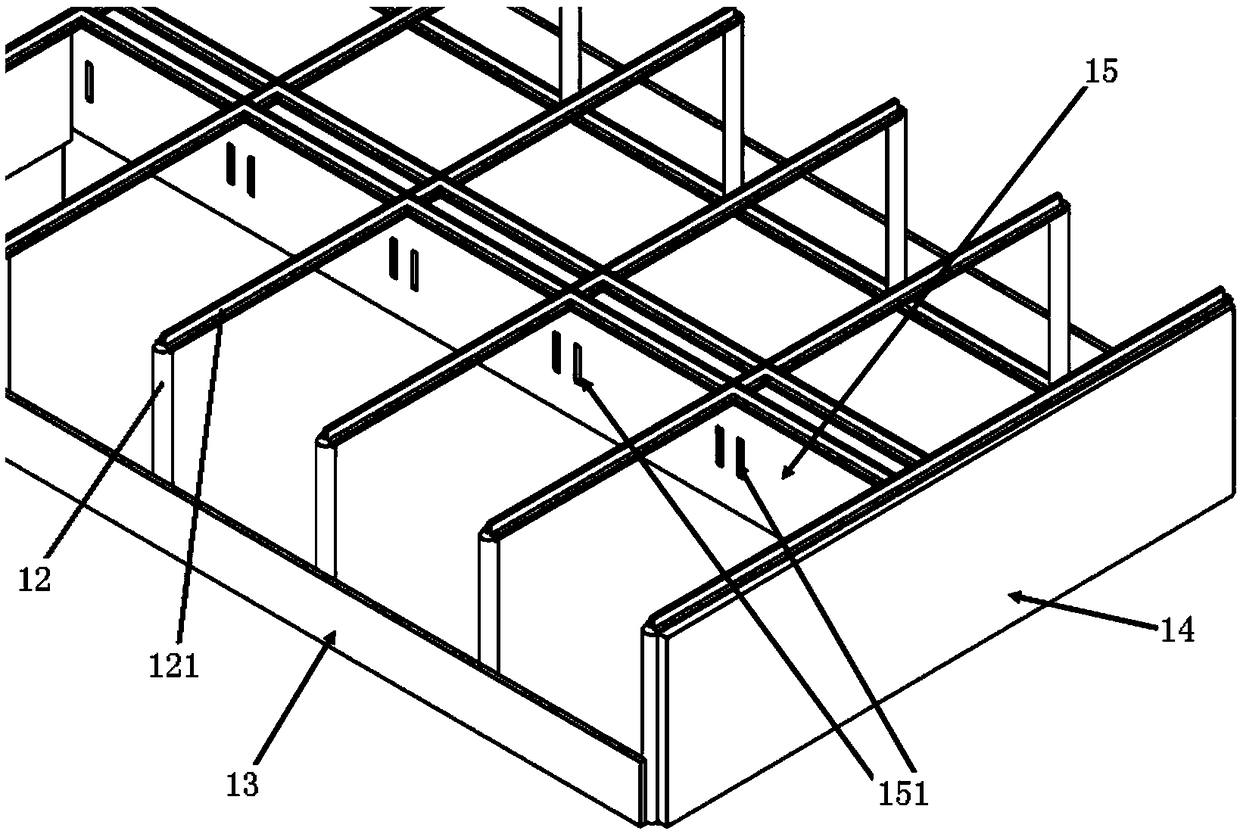

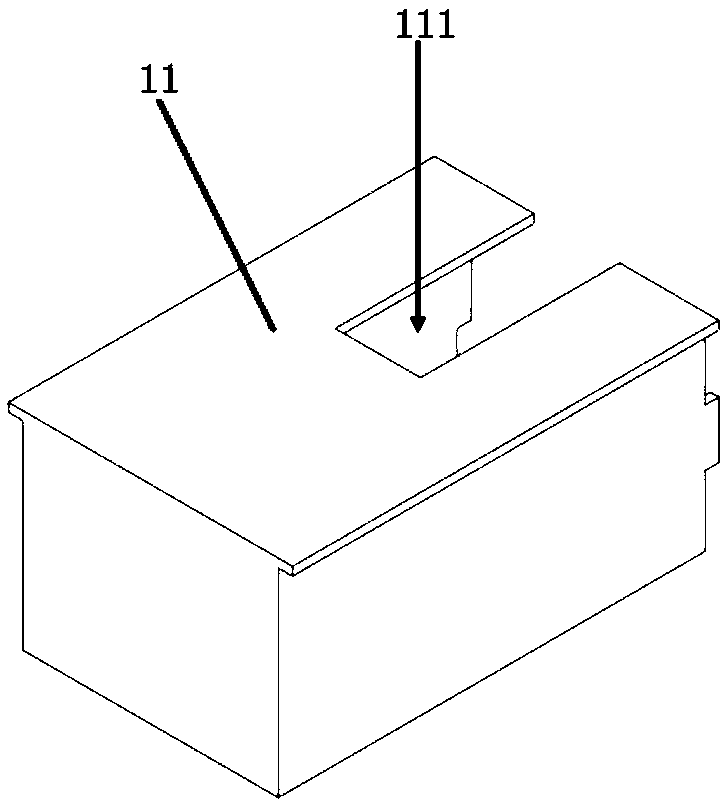

[0038] see figure 1 , the controllable aluminum electrolytic cell anode cover sealing system in the figure includes a support frame 12 and several anode cover units 11 (in order to show the internal structure of the support frame, only one of the anode cover units is shown in the figure), wherein, the support The frame 12 is a frame structure formed by welding several stainless steel rods and mounted on the top of the aluminum electrolytic cell. It is formed by welding several stainless steel rods distributed in parallel. The anode carbon blocks 8 are distributed between the gaps at the top of the support frame 12, and the connected anode guide rods 81 protrude from the gaps of the support frames 12 to connect with the anode bus bar. The anode is covered The unit 11 is covered on the anode carbon block 8 and embedded on the top of the supporting frame to cover the upper part of the anode carbon block 8 and form a seal on the top of the supporting frame 12 .

[0039] Concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com