Heat electricity combination supply method and device adopting gradient utilization of middle-low temperature waste heat

A technology of low-temperature waste heat and cogeneration of heat and power, which is applied to machines that use waste heat, steam engine devices, and machine operation methods, and can solve problems such as inability to be developed and utilized, lack of heat demand, and lack of power generation utilization technology to reduce heat supply. Cost, expansion of utilization temperature zone, and improvement of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

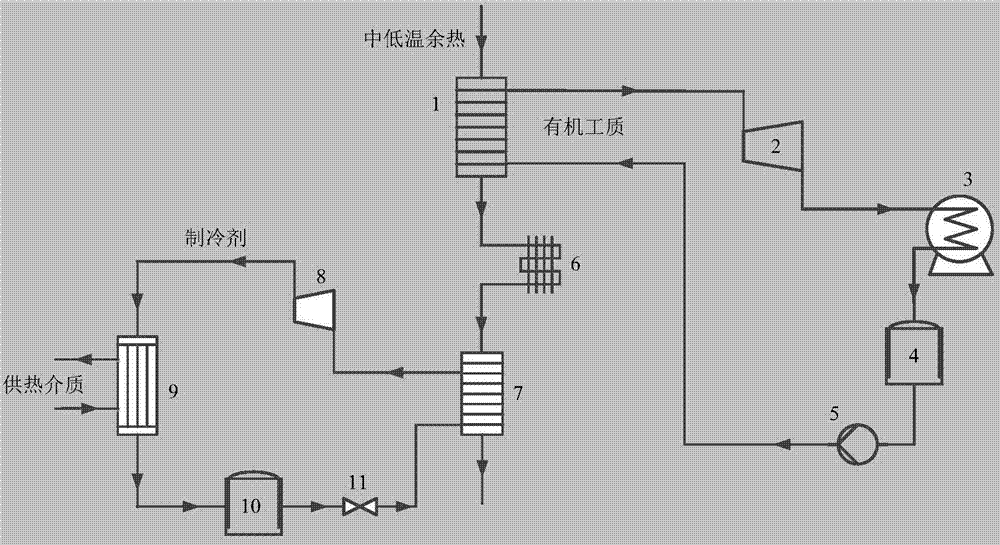

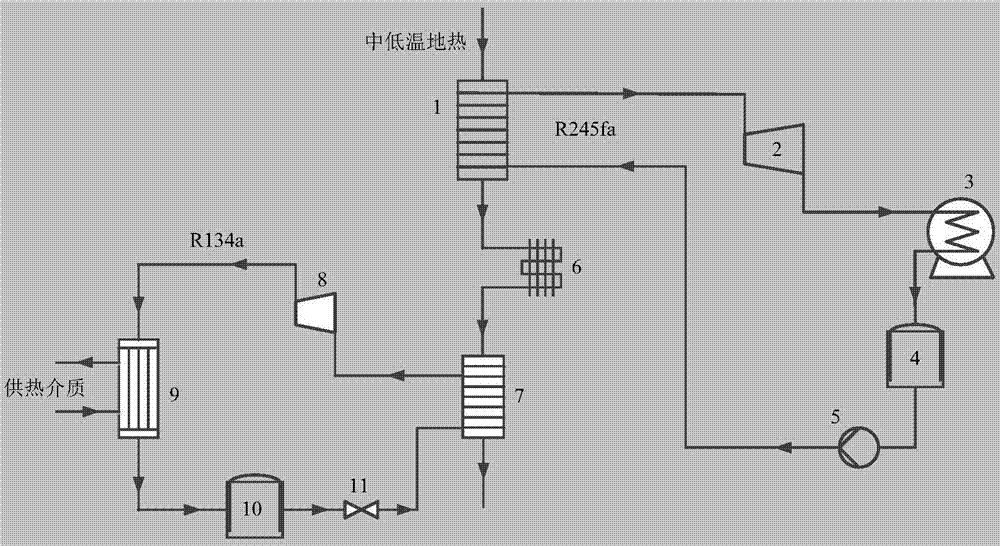

[0030] Such as figure 1 As shown, the present invention is a cascaded heat and power cogeneration device utilizing medium and low temperature waste heat, including:

[0031] Primary evaporator 1;

[0032] Expander 2, the organic working medium inlet of which is connected to the organic working medium outlet of primary evaporator 1;

[0033] Condenser 3, its organic working medium inlet is connected with the organic working medium outlet of expander 2;

[0034] Storage tank one 4, its organic working medium inlet is connected with the organic working medium outlet of condenser 3;

[0035] Working medium pump 5, its organic working medium inlet is connected with the organic working medium outlet of storage tank one 4, and the organic working medium outlet is connected with the organic working medium inlet of primary evaporator 1;

[0036] Radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com