Direct expansion type solar assisted closed-loop type heat pump drying system

A technology of heat pump drying and solar energy, which is applied in the direction of solar thermal power generation, drying, dryers, etc., can solve the problems of serious environmental pollution, difficult temperature adjustment, slow drying speed, etc., achieve green resources and expand application fields , The effect of power consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

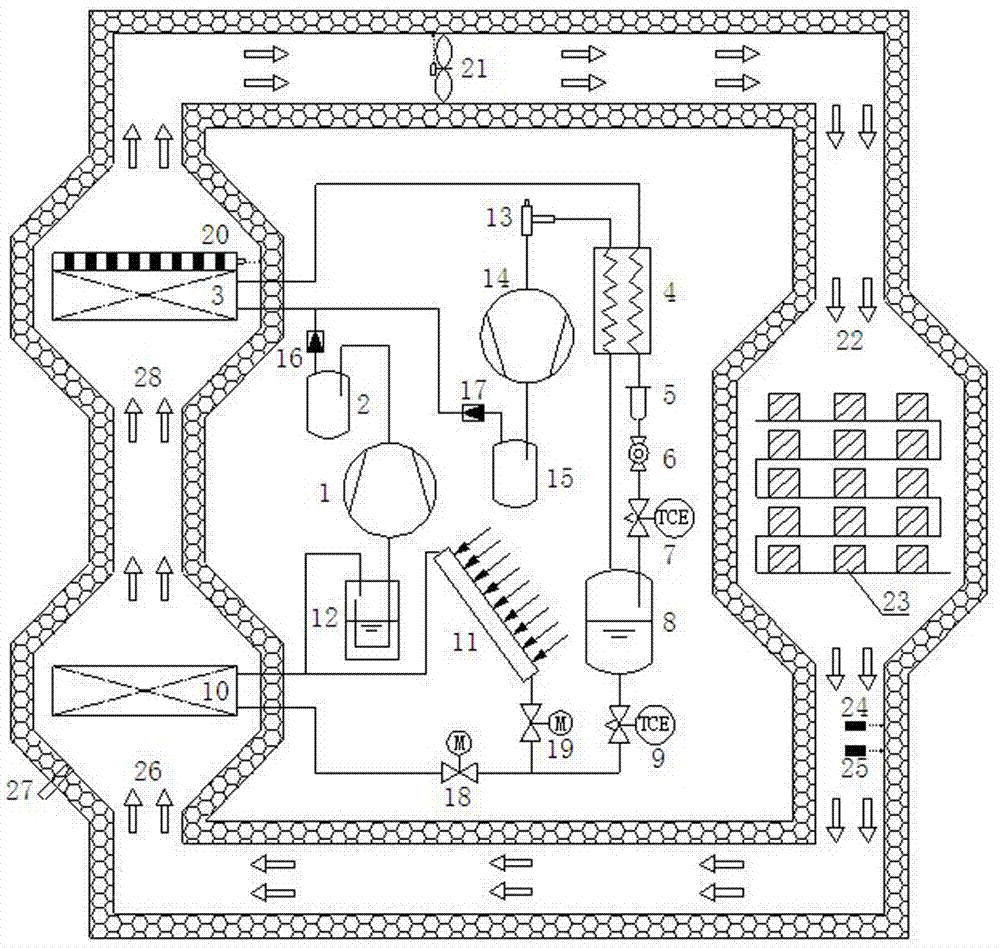

[0024] Such as figure 1As shown, the present invention provides a direct expansion solar-assisted closed-circuit heat pump drying system, which is characterized in that the system is mainly composed of a solar-air three-pressure heat pump subsystem and a closed-circuit drying medium circulation subsystem. The solar-air three-pressure heat pump subsystem described therein consists of a main road compressor 1, a main road oil separator 2, a main road condenser 3, a recooler 4, a dry filter 5, an observation mirror 6, and a first expansion valve 7. Medium-pressure gas-liquid separator 8, second expansion valve 9, dehumidification evaporator 10, solar collector 11, low-pressure gas-liquid separator 12, evaporation pressure regulating valve 13, auxiliary circuit compressor 14, auxiliary circuit oil separator 15, The first one-way valve 16, the second one-way valve 17, the first electric regulating valve 18, the second electric regulating valve 19 and connecting pipelines are compos...

Embodiment 2

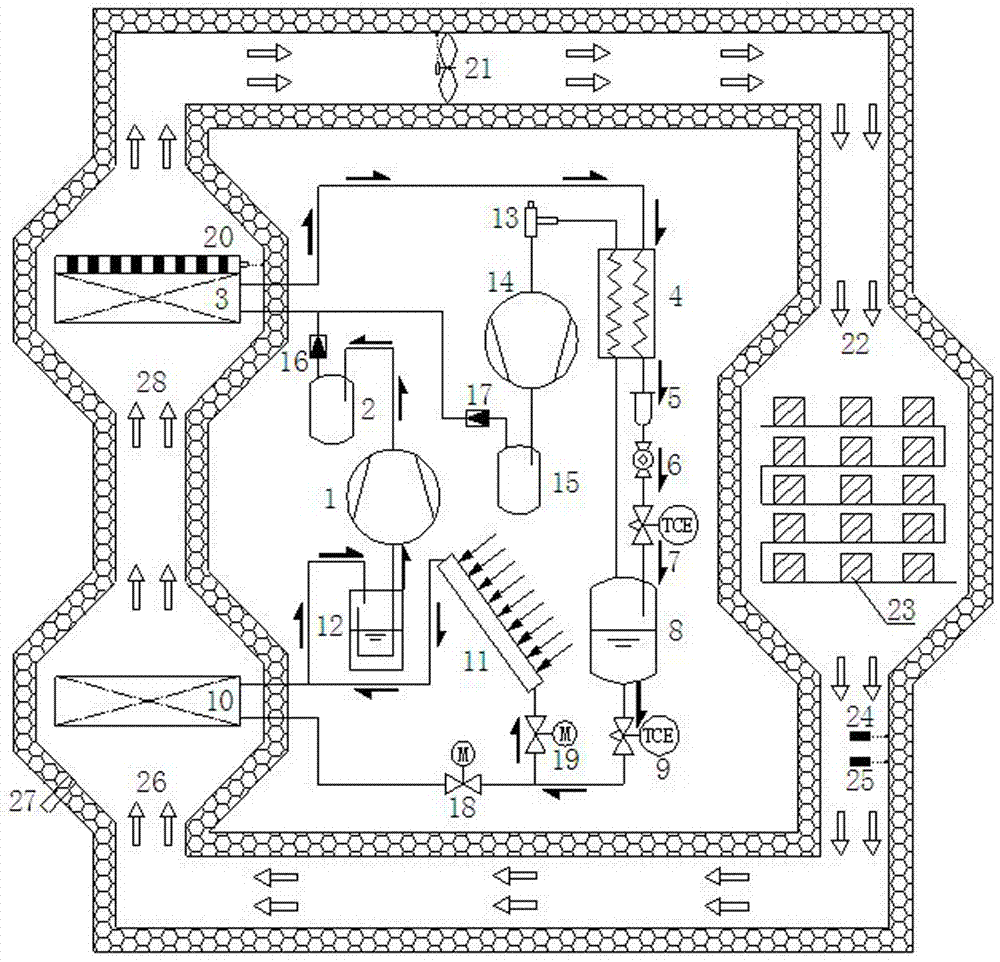

[0027] The main road compressor 1 described in the present invention is a fixed-frequency scroll compressor, and the auxiliary road compressor 14 is a fixed-frequency rolling rotor compressor; the main road condenser 3 is a finned tube heat exchanger, a dehumidifier The evaporator 10 is a parallel flow heat exchanger; the first expansion valve 7 is a float type expansion valve, and the second expansion valve 9 is a flow resistance expansion valve; the circulating fan 21 is a fixed frequency fan; The evaporating pressure regulating valve 13 mentioned above is a proportional differential regulating valve controlled by the pre-valve pressure (ie evaporating pressure); the described subcooler 4 is in the flasher. Other structures are the same as in Embodiment 1.

Embodiment 3

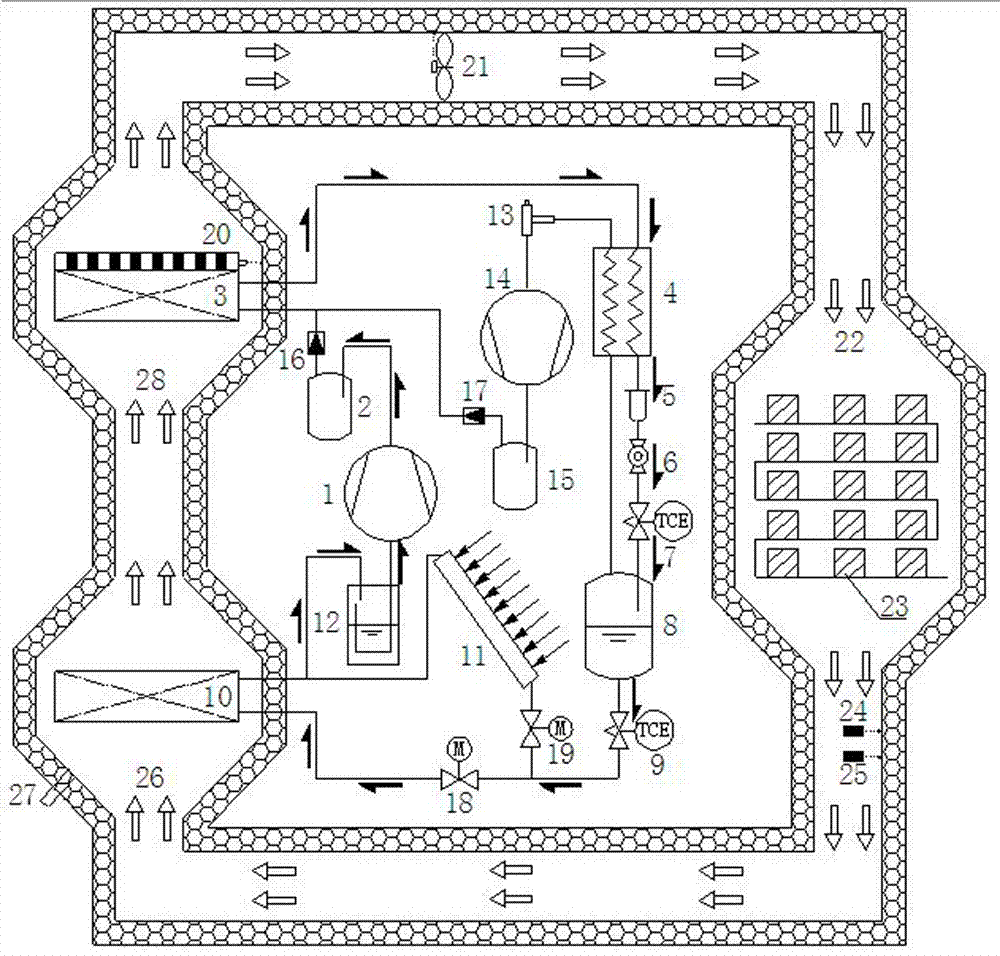

[0029] The main circuit compressor 1 of the present invention is a frequency conversion rolling rotor compressor, and the auxiliary circuit compressor 14 is a frequency conversion scroll compressor; the main circuit condenser 3 is a stacked heat exchanger, and the dehumidification evaporator 10 is a parallel compressor. flow heat exchanger; the first expansion valve 7 is a float type expansion valve, and the second expansion valve 9 is a thermal expansion valve; the circulating fan 21 is a frequency conversion fan; the evaporation pressure regulating valve 13 is A proportional-integral-differential regulating valve controlled by the pre-valve pressure (that is, evaporation pressure); the subcooler 4 is a casing heat exchanger. Other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com