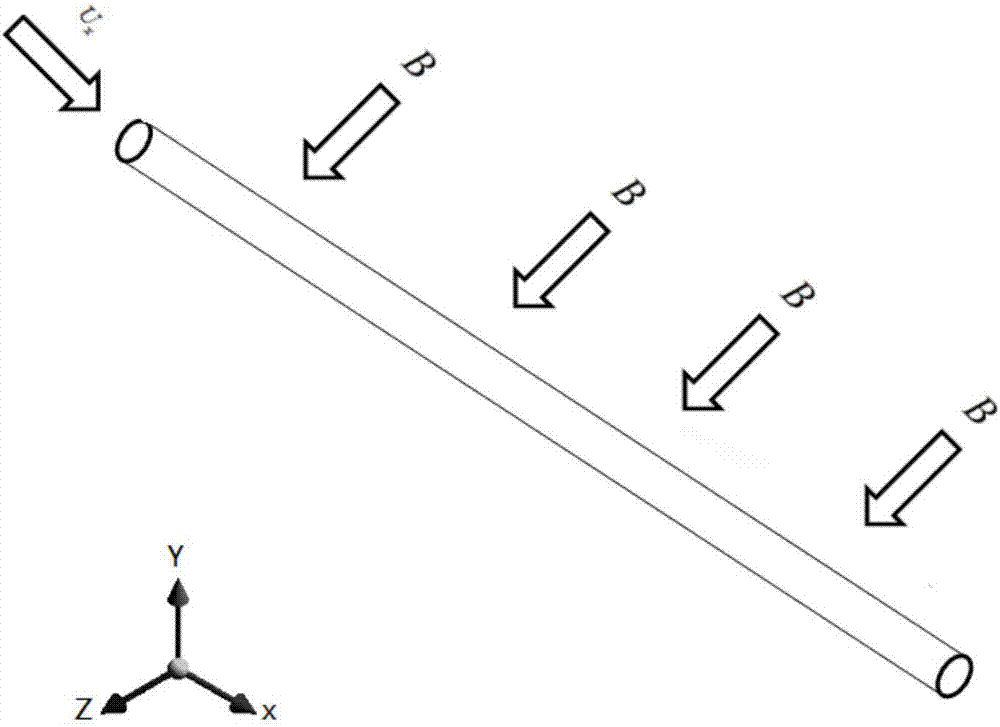

Method for reducing ablation problem in weapon body pipe by using magnetic control plasma

A plasma and body tube technology, applied in the field of weapons, can solve the problems of long production cycle, high cost, and difficulty in popularization and use, and achieve the effect of reducing wall temperature, reducing efficiency, and weakening heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

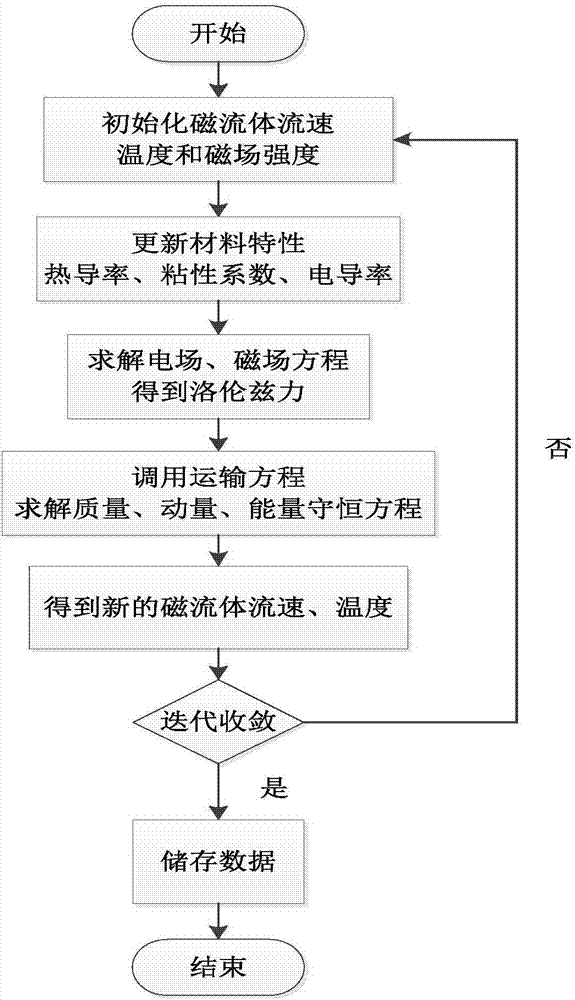

Method used

Image

Examples

Embodiment 1

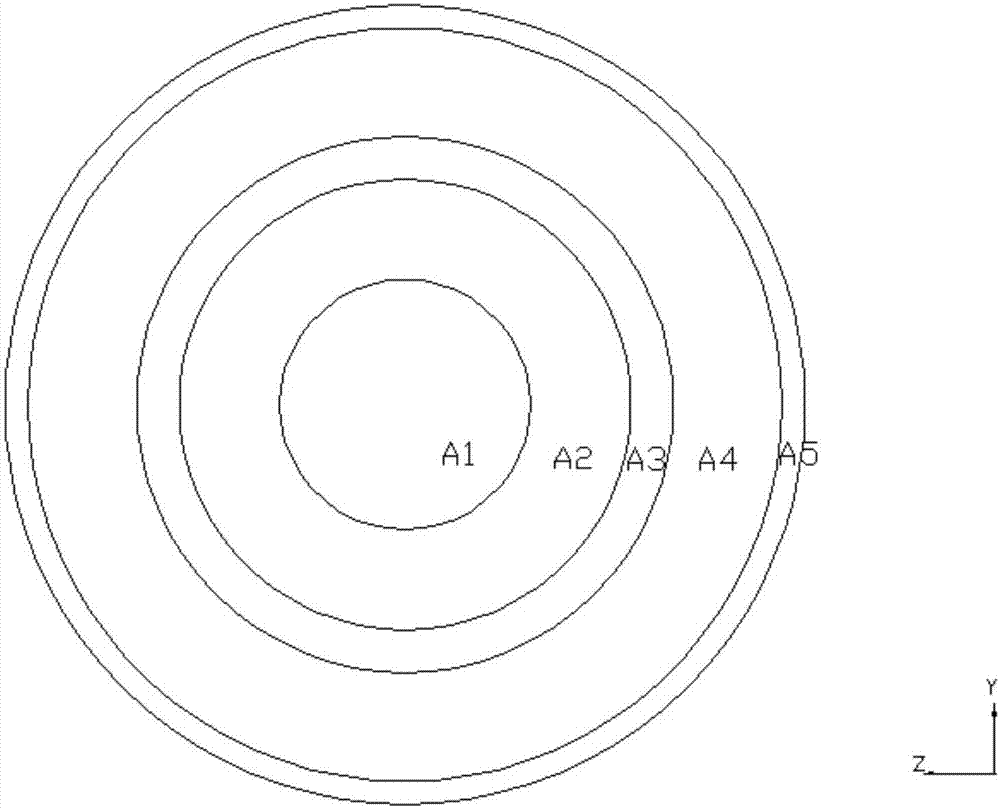

[0034] Discuss the influence of electromagnetic intensity B on the temperature of the inner wall of the cylinder:

[0035] Bring B=0T, B=0.5T, B=1T, B=2T into the solution process of turbulent kinetic energy respectively, image 3 shows the turbulent kinetic energy distribution at B=0T, Figure 4 shows the turbulent kinetic energy distribution for B=0.5T, Figure 5 The temperature curves of the inner wall of the cylinder under different magnetic fields are shown. It can be seen from the figure that the heat transfer of the high-temperature gas to the wall surface decreases after the external magnetic field is applied. With the increase of the magnetic field, the heat insulation effect is more obvious. This is because the magnetic field reduces the turbulent kinetic energy of the fluid, and its heat transfer ability is correspondingly weakened.

[0036] It can be seen that the magnetic field perpendicular to the flow direction of the conductive gas can change its flow field s...

Embodiment 2

[0038] Discuss the effect of conductivity σ on the temperature of the inner wall of the cylinder:

[0039] In the case of applying a 0.5T magnetic field, set the conductivity of the plasma to 0 to 10000S / m, Figure 6 The temperature curves of the inner wall under different conductivity are shown. When the conductivity σ is lower than 1000S / m, the induced current density of the fluid under the action of the magnetic field is small, and the Lorentz force on the magnetic fluid is correspondingly reduced, and the turbulence is suppressed. The effect is weak. Therefore, the temperature change curve basically coincides with the curve with zero conductivity. When the conductivity continues to increase to 5000S / m, the induced current density increases, and it can be seen that the temperature curve has changed significantly, and the temperature of the inner wall of the cylinder has been effectively reduced, and as the conductivity continues to rise, The insulation effect is gradually...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com