Device and method for in-situ precision measurement of tiny holes in small and medium-diameter cylindrical components

A precision measurement, small and medium-caliber technology, applied in measurement devices, instruments, etc., can solve the problems of low processing consistency, small hole measurement accuracy error, increase detection time, etc., to reduce human measurement errors, ensure high-precision measurement, improve The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

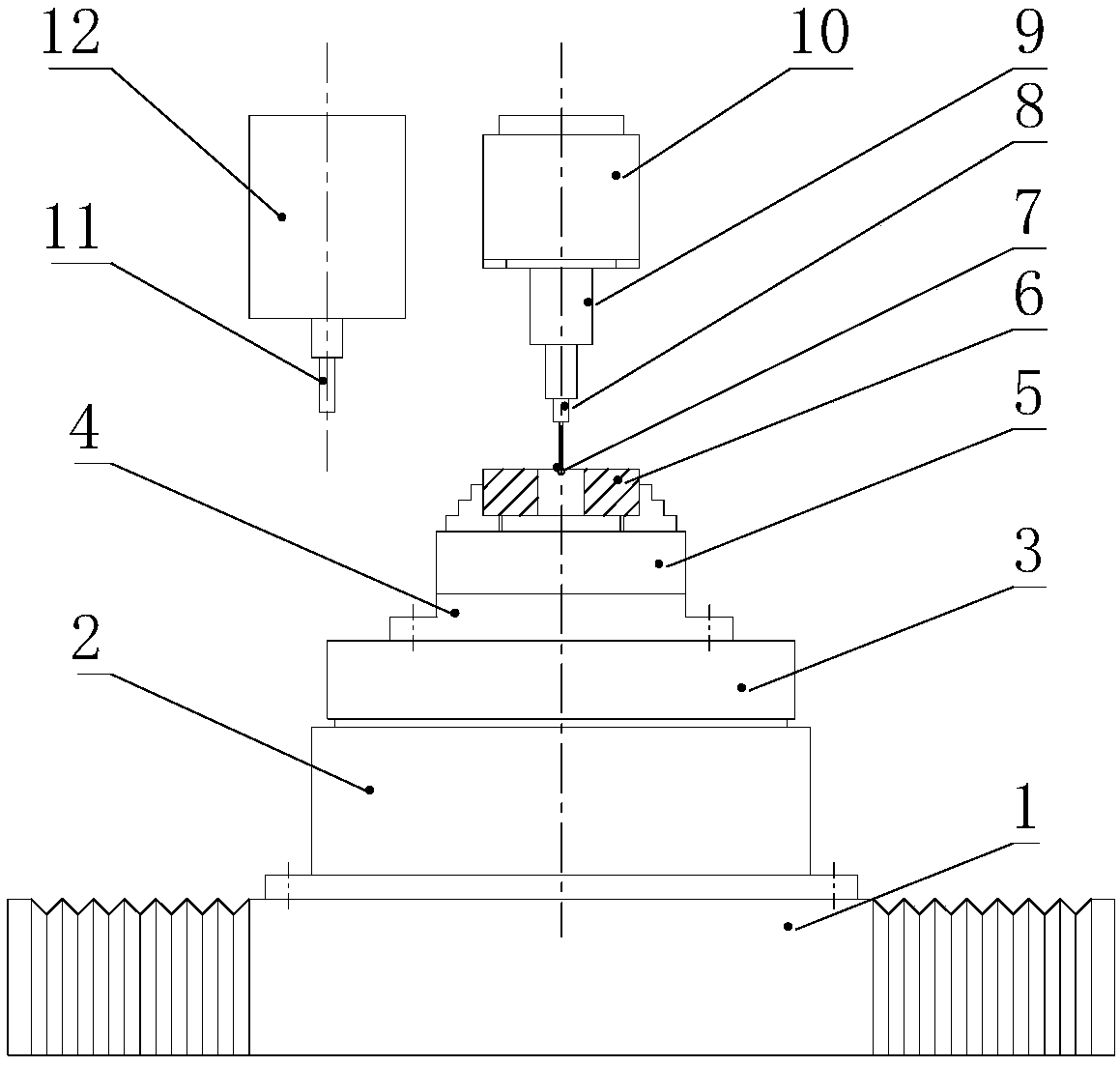

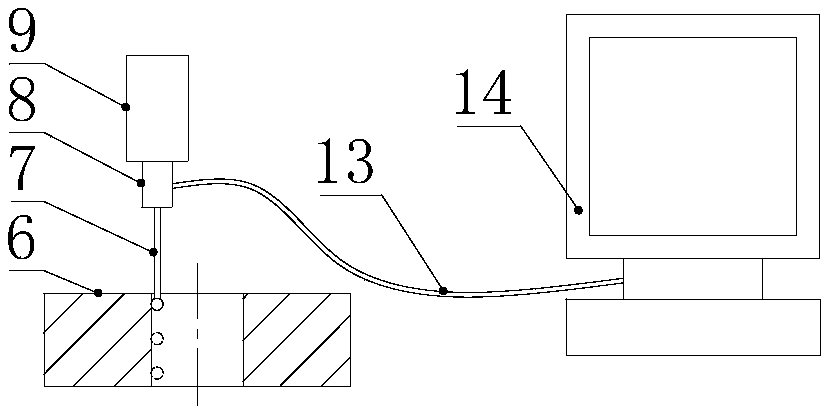

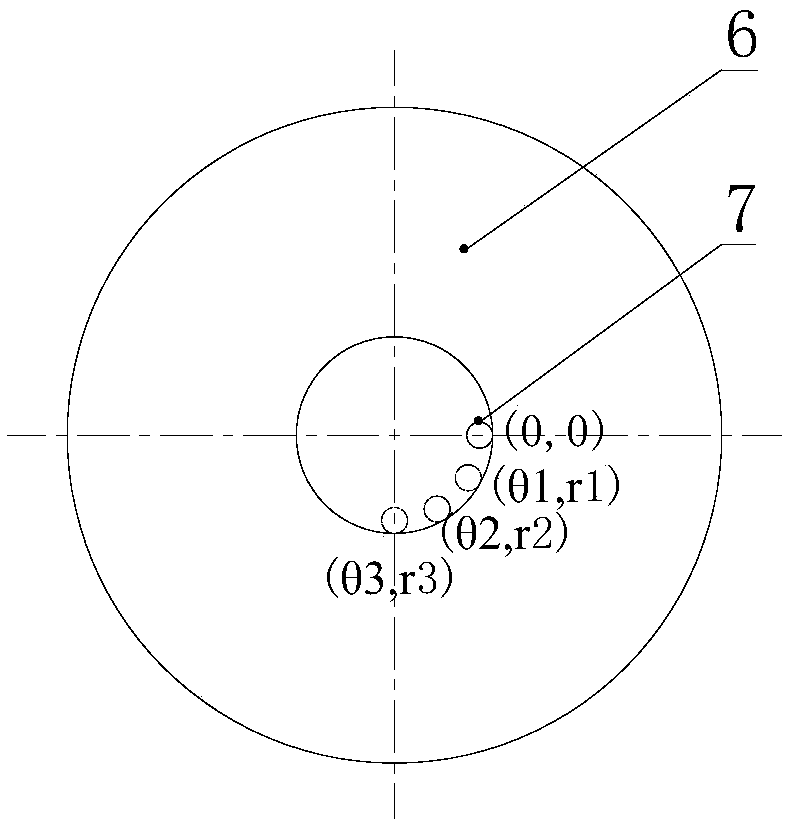

[0029] The present invention provides a precise measurement device and method for in-position micro-holes of small and medium-diameter cylindrical elements. Through the high-precision guiding and driving system of the gas static pressure guide rail pair of the machine tool itself, and the high-precision rotary system of the gas static pressure turntable, the precision measurement device is used. Detect the size and shape accuracy of the tiny hole in the center of the cylindrical element. The cylindrical element is clamped on the turntable part, and the measuring device is installed at the bottom of the cylinder, which can perform telescopic movement, so that the Z-axis of the detection ball head can be guided in the X-direction guide pair. The direction of motion passes through the center of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com