Fly dropping type single liquid droplet combustion system

A combustion system, flying drop technology, applied in the direction of using combustion for chemical analysis, etc., can solve problems such as limited temperature range, difficulty in meeting the use of lubricating oil, and negative effects on temperature field stability, and achieve the effect of a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

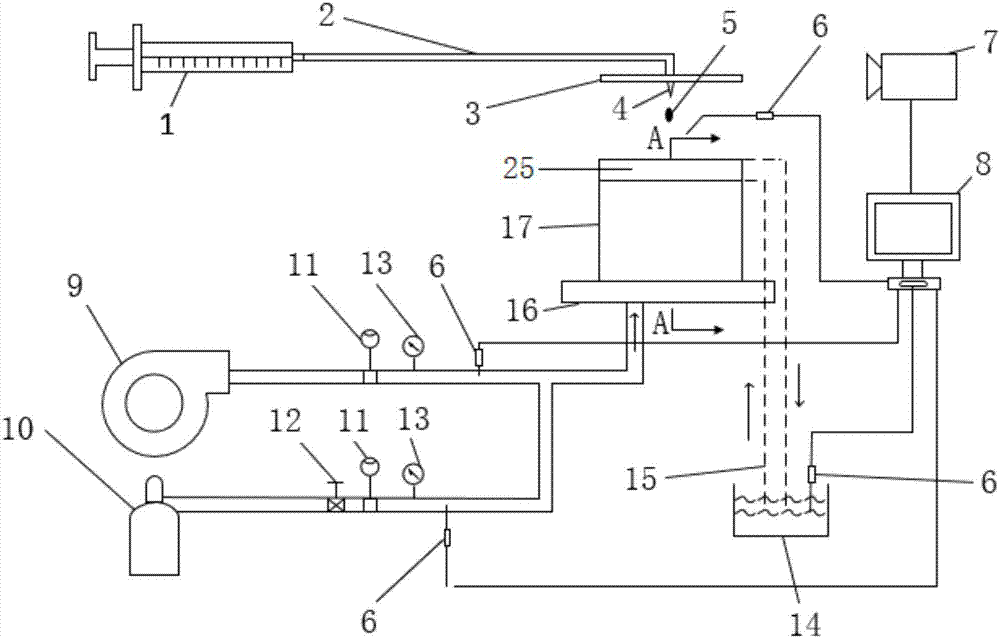

[0022] A flying drop single droplet combustion system such as figure 1 As shown, it includes a droplet conveying unit for delivering flying droplet 5 , a burner unit for providing a high temperature environment, an air supply unit for providing gas fuel to the burner unit, and a recording unit for recording the combustion state of single droplet 5 .

[0023] The liquid drop delivery unit is arranged on the upper part of the burner unit, including a microinjector 1, a needle tube 2 connected to the microinjector 1, and a needle 4 installed at the end of the needle tube 2. 0.1-0.3mm, 0.2mm in this embodiment, and separated from the burner unit by the heat insulating baffle 3.

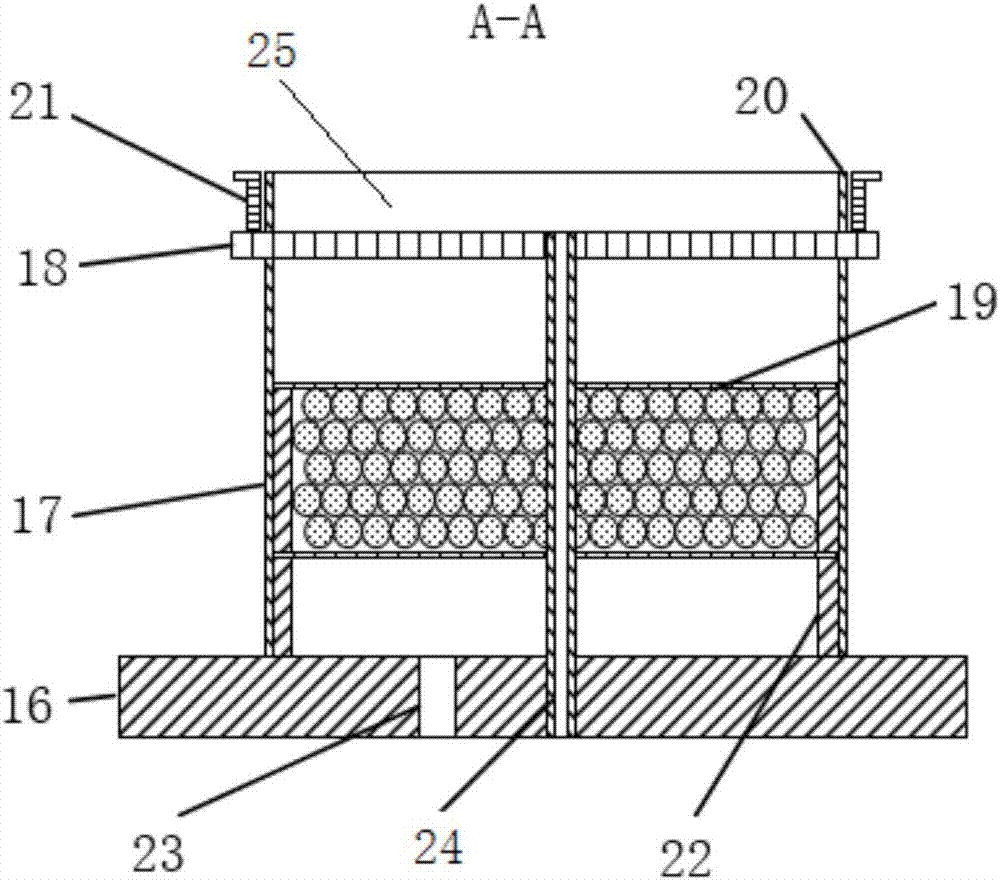

[0024] Such as figure 2 As shown, the burner unit is cylindrical, including a base 16, a housing 17 disposed on the base 16, and a porous combustion disc 18 disposed on the upper part of the housing 17. The upper part of the porous combustion disc 18 is provided with an outer retaining ring 20, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com