Method and device for promoting output characteristics of Nd:YAG laser device

An output characteristic, laser technology, applied in laser cooling devices, lasers, laser parts and other directions, can solve the problems of restricting high output power and high beam quality, weakening the thermal effect of the slats, etc., to achieve reduced thermal effect, easy engineering application, The effect of good beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

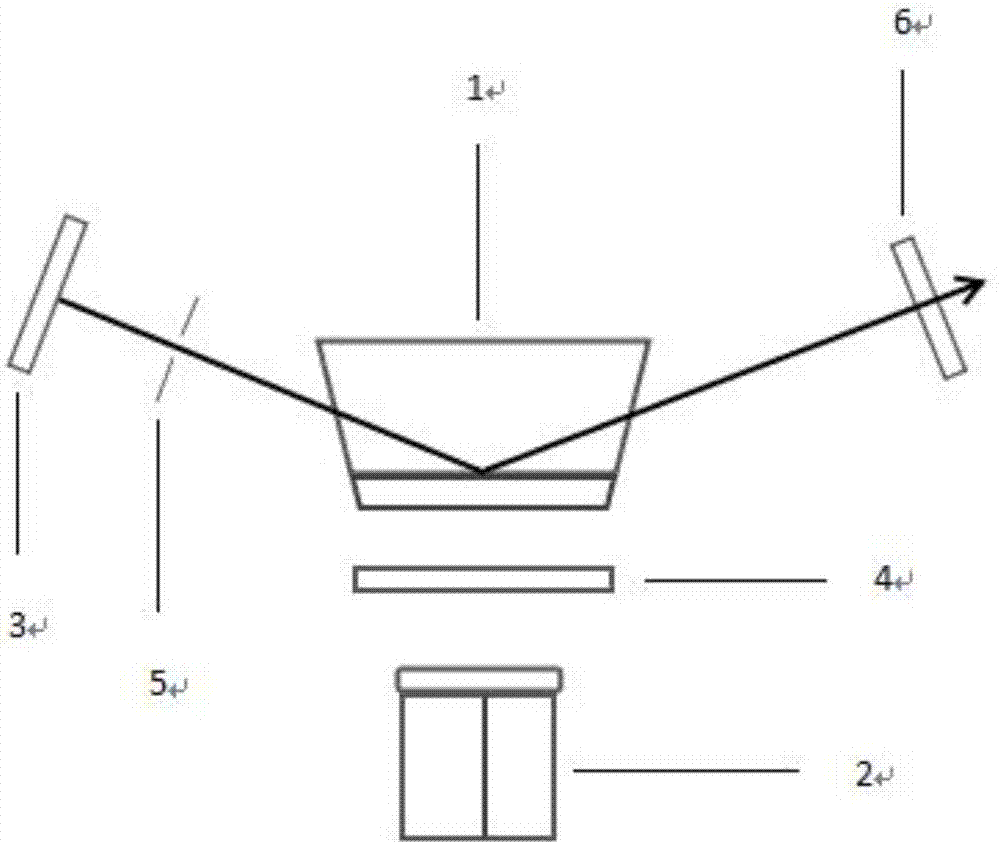

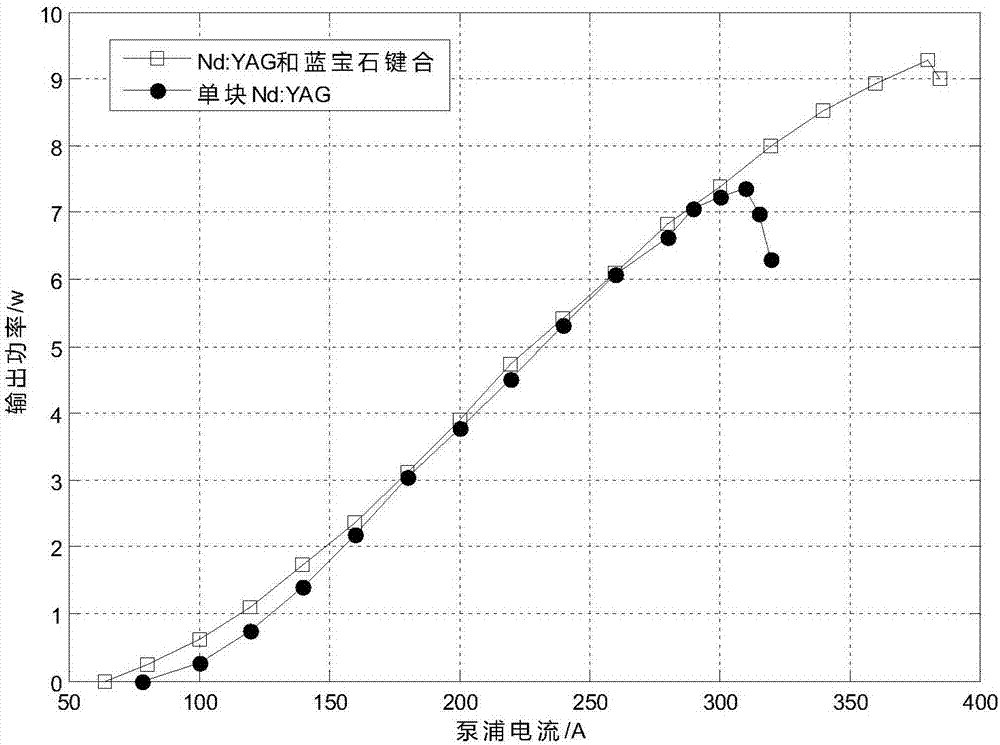

[0021] Attached below Figure 1 to Figure 2 Further explanation of this new laser oscillator:

[0022] refer to figure 1 , figure 1 It is the structural diagram of the slab laser oscillator. Depend on figure 1 It can be seen that the oscillator is composed of a trapezoidal slab laser gain medium 1 , a pump source 2 , a total reflection mirror 3 , a cylindrical mirror 4 , an aperture 5 , and an output mirror 6 .

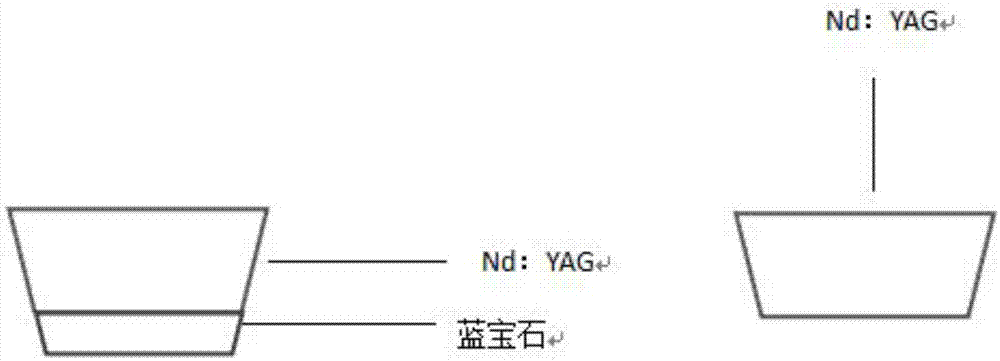

[0023] The trapezoidal slab laser gain medium is a bonded crystal of sapphire and Nd:YAG.

[0024] The pumping source is a stack of four semiconductor bars with a peak power of 500w.

[0025] The total reflection mirror is a 1064 0-degree total reflection.

[0026] The cylindrical mirror is a cylindrical mirror with a focal length of 70mm, which is used to focus the pump light in the vertical direction.

[0027] The aperture is a circular aperture aperture with a diameter of 1.5mm.

[0028] The output mirror is an output mirror with a transmittance of 30%. It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com