Driver parallel connection system control method considering current sharing and motor control effect

A technology of motor control and control method, which is applied in the direction of control system, vector control system, motor generator control, etc. It can solve the problems of poor adaptability and complex control, and achieve the effects of reducing derating, improving dynamic performance, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The method of the present invention will be described below in conjunction with the accompanying drawings.

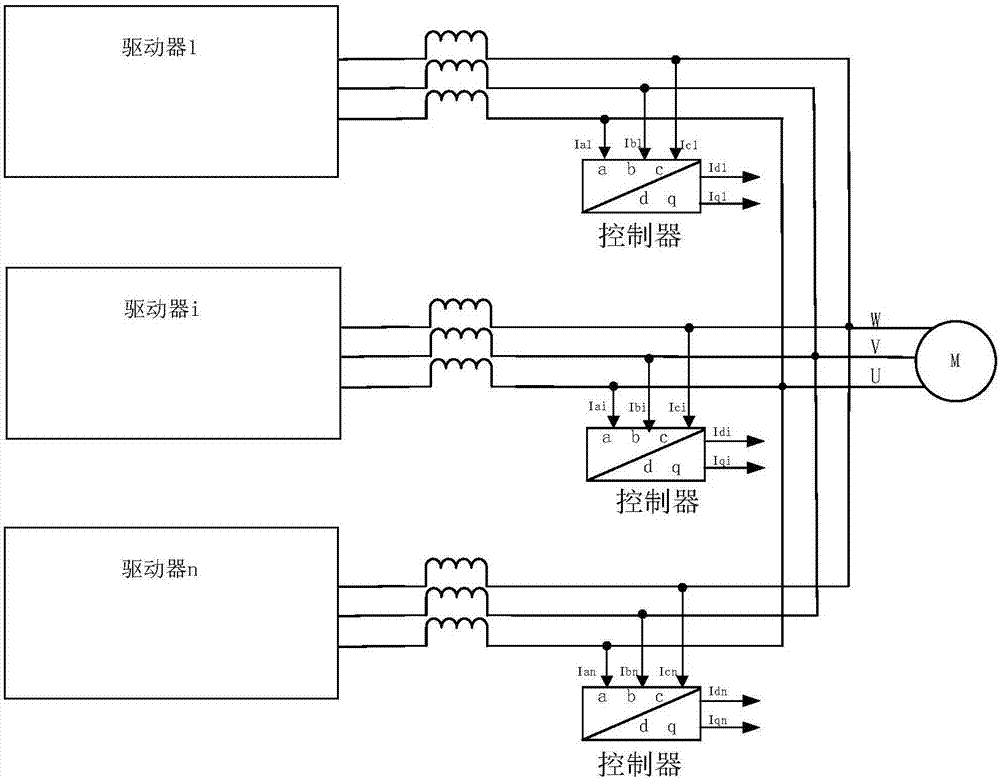

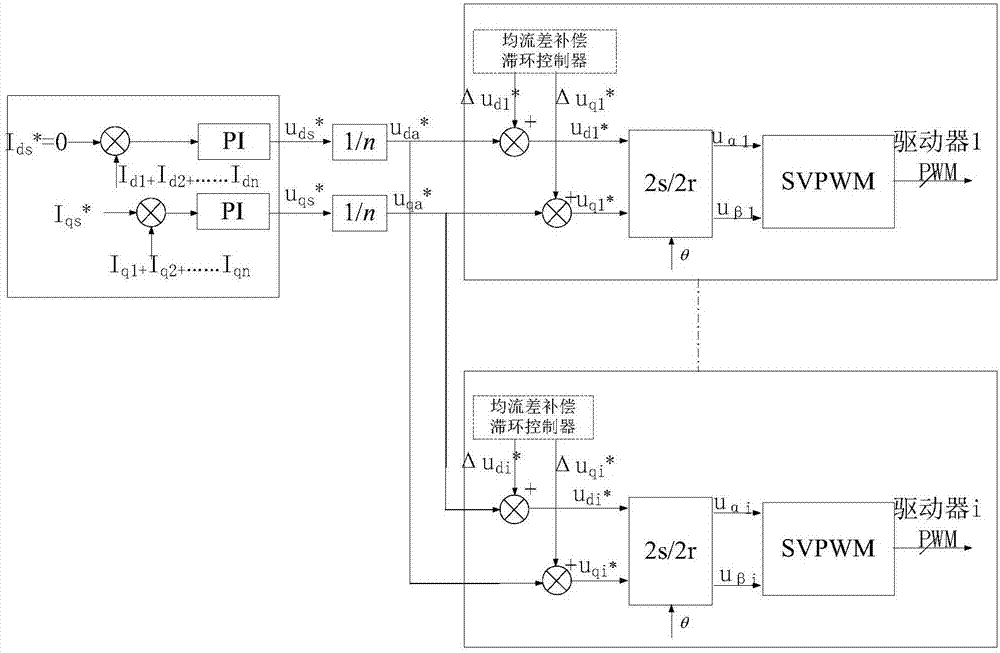

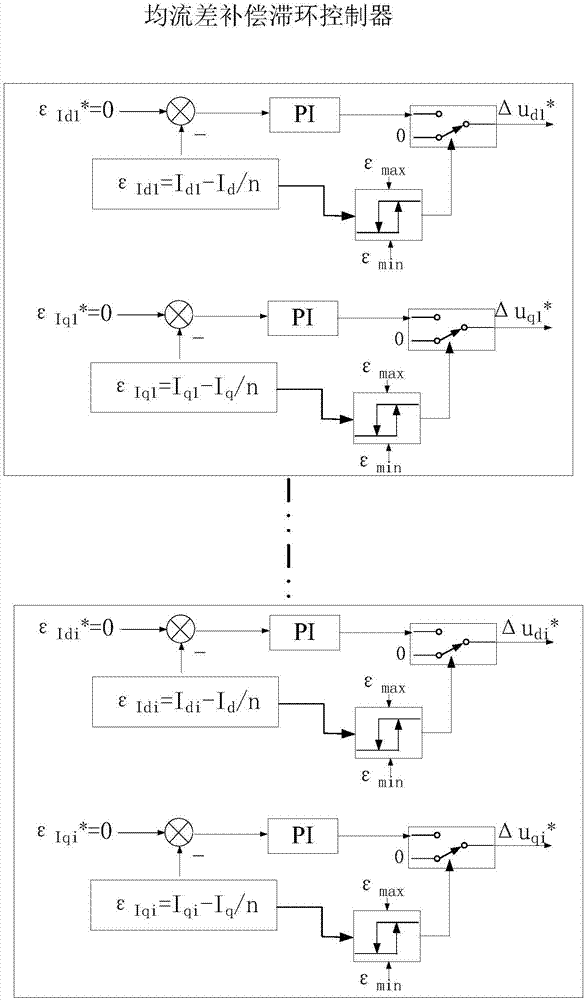

[0020] The present invention proposes a method that takes into account both current sharing and motor control effects. The applicable system outputs series current sharing reactors through the AC side of n drivers and then directly connects them in parallel. Drivers 1 to 1 perform data interaction and PWM carrier synchronization through a high-speed bus. control, such as figure 1 shown. Observe the difference between the d-axis and q-axis currents output by each driver and the d-axis and q-axis currents shared by the system, and choose to adjust or not adjust the current according to the magnitude of the current deviation. When it is observed that the difference between the output d-axis and q-axis current of one of the drivers in the parallel system and the system's average d-axis and q-axis current exceeds the upper limit of the current difference threshold ε ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap