Magnetic suspension and magnetic drive multi-axis flexible transposition device

A technology of displacement device and magnetic drive, which is applied in the direction of holding device, auxiliary device, auxiliary welding equipment, etc. with magnetic attraction or thrust, which can solve the problem that the precision and stability cannot meet the requirements of welding positioner, curve welding, and mobile response. Long time and other problems to achieve the effect of avoiding magnetic confusion, avoiding errors and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1: Checking the workpiece

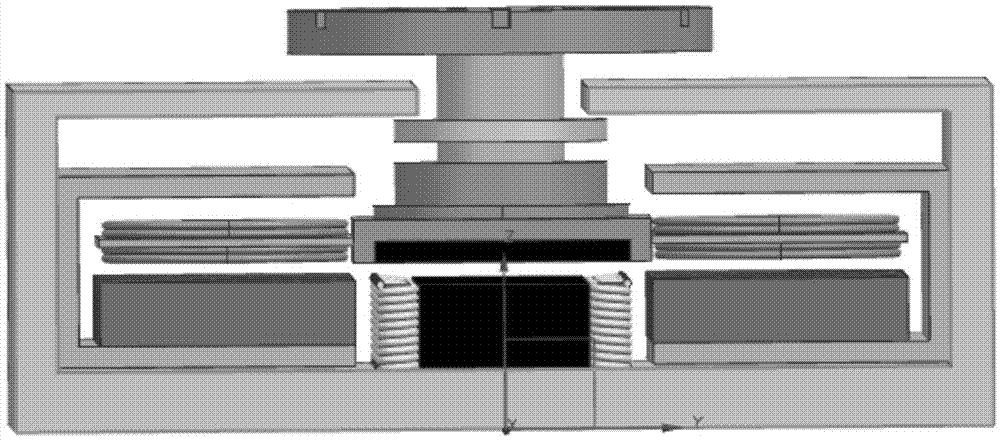

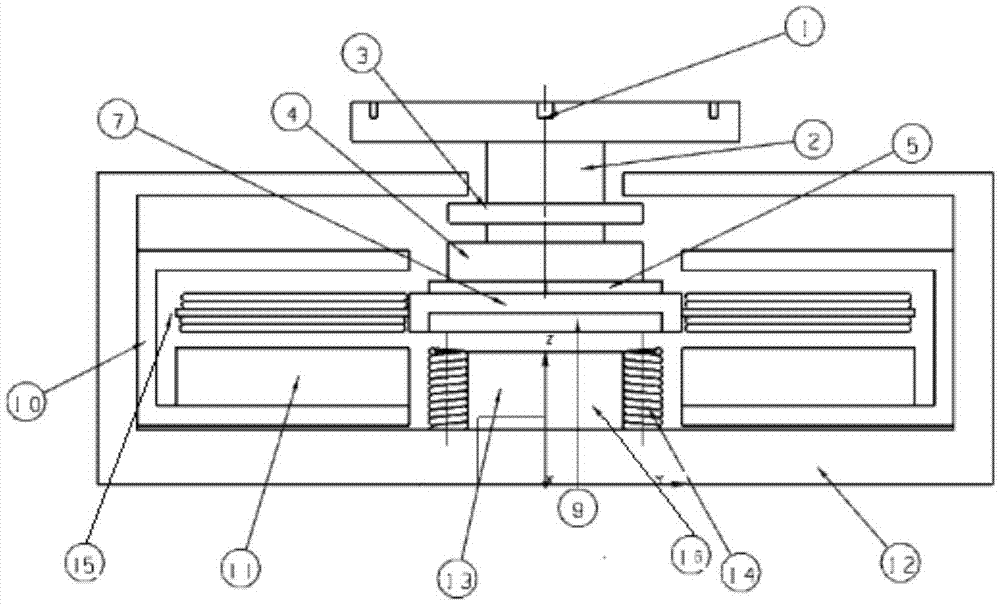

[0065] combine figure 1 , figure 2 and Figure 7 , a magnetically levitated and magnetically driven multi-axis flexible displacement device, the workpiece is placed on the working platform 1 and fixed with a fixture, and then the coil winding 14 is energized, and the platform is suspended to the desired position by adjusting the magnitude and direction of the current in the coil height, then energize the printed coil 8 to move the mobile platform 7 and the working platform 1 to the desired position, then cut off the power to the printed coil 8, and then energize the rotating coil 4, and the working platform 1 rotates to make the workpiece inspection area Inside, then cut off the power to the rotating coil 4, and then carry out the inspection work, after the inspection work is completed, cut off the power to the coil winding 14, take off the workpiece, and the inspection work is completed.

Embodiment 2

[0066] Example 2: Welding a straight line seam

[0067] combine figure 1 , figure 2 and Figure 7 , a magnetic levitation and magnetic drive multi-axis flexible displacement device, the weldment is installed on the working platform 1 and fixed, and then the coil winding 14 is energized, and the platform is suspended to the desired height by adjusting the magnitude and direction of the current in the coil , energize the rotating coil 4, the working platform 1 rotates, adjust the magnitude and direction of the current, make the welding seam parallel to the track, then turn off the power to the rotating coil 4, the welding torch starts to work, and at the same time energize the coils a and b on the coil frame 15, Make the mobile platform move forward, after the weld seam is welded, the coils a, b are de-energized, the coil winding 14 is de-energized, the weldment is taken off, and the welding is completed.

Embodiment 3

[0068] Example 3: Welding curve weld seam

[0069] combine figure 1 , figure 2 and Figure 7 , a magnetic levitation and magnetic drive multi-axis flexible displacement device, the weldment is installed on the working platform 1 and fixed, and then the coil winding 14 is energized, and the platform is suspended to the desired height by adjusting the magnitude and direction of the current in the coil , energize the rotating coil 4, energize the coils a and b in turn, start the welding torch, adjust the current magnitude and direction of the rotating coil 4 and coils a and b, so that the movement track of the working platform 1 is consistent with the welding seam of the weldment until the welding seam After the welding is completed, the coils a and b are powered off, the coil winding 14 is powered off, the weldment is removed, and the welding is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com