Embedded reinforcing component for polyurethane cold storage board core material

A technology of reinforced components and polyurethane sandwich panels, which is applied in building construction, construction, etc., can solve the problems of reduced thermal insulation performance of cold storage panels, influence of thermal insulation performance of cold storage panels, and greater impact of thermal insulation performance of cold storage panels, etc., to achieve low production costs , Conducive to the promotion of production and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

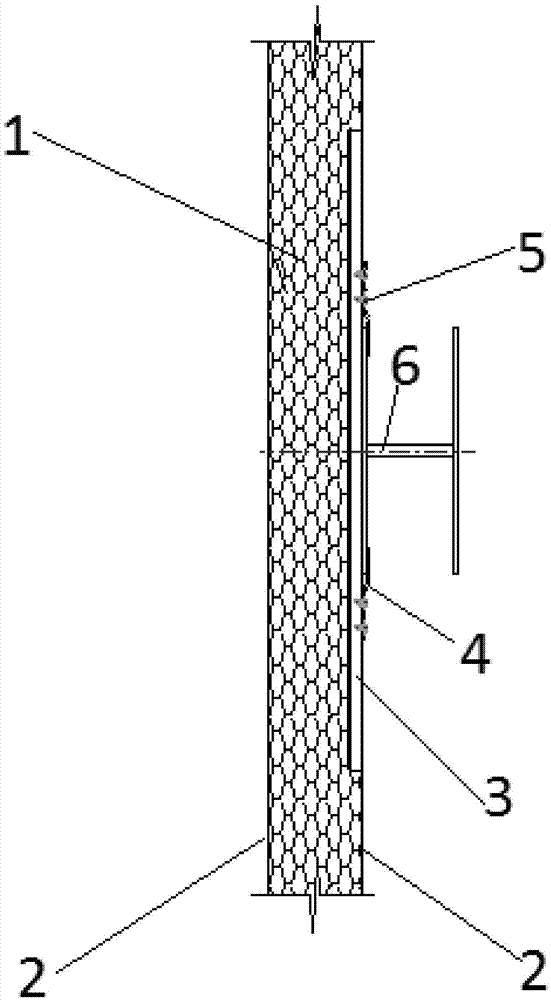

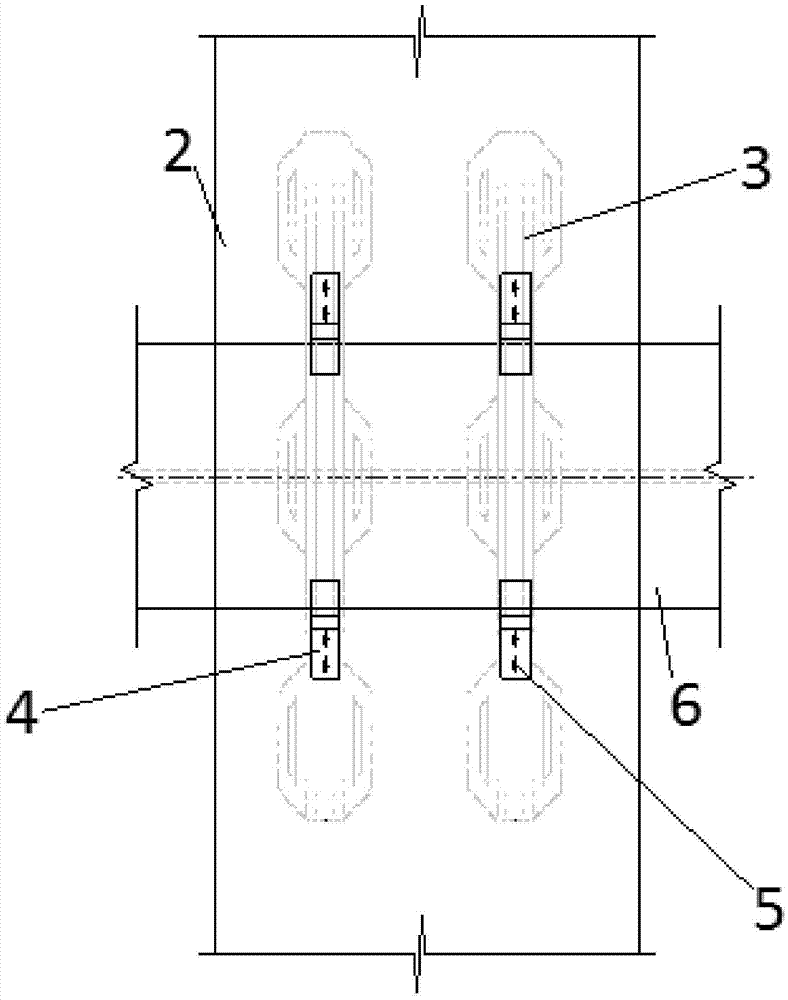

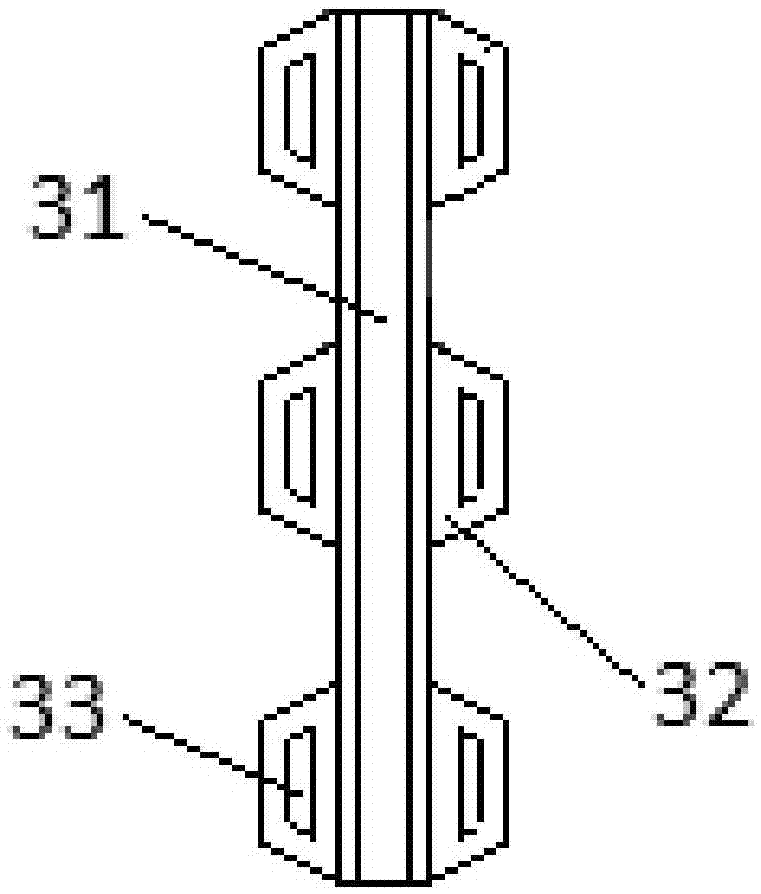

[0030] Such as Figure 1-2 As shown, a pre-embedded reinforcement member for polyurethane cold storage panel core material, the reinforcement member is used to fixedly connect the cold storage panel and the steel beam 6, the cold storage panel includes a polyurethane sandwich panel 1 and is wrapped inside and outside the polyurethane sandwich panel 1 The metal panels 2 on both sides, the strengthening member includes a plurality of anti-pullout units 3 embedded in the polyurethane sandwich panel 1 parallel to each other, and elastic compression units 4 arranged on the metal panels 2 and fixedly connected with the anti-pullout units 3 , each anti-drawing unit 3 is fixedly connected with multiple pairs of elastic compression units 4 through connecting elements 5, and each pair of elastic compression units 4 constitutes a pair of crimping joints for assembling steel beams 6, and steel beams 6 are elastically compressed The solid unit is fixedly connected with the cold storage boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com