Flow path switching valve

A flow path switching and valve chamber technology, applied in the field of flow path switching valves, can solve the problems of opening area changes, miniaturization difficulties, and complicated structures, etc., to reduce the driving torque, reduce the pressure difference, and reduce the load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

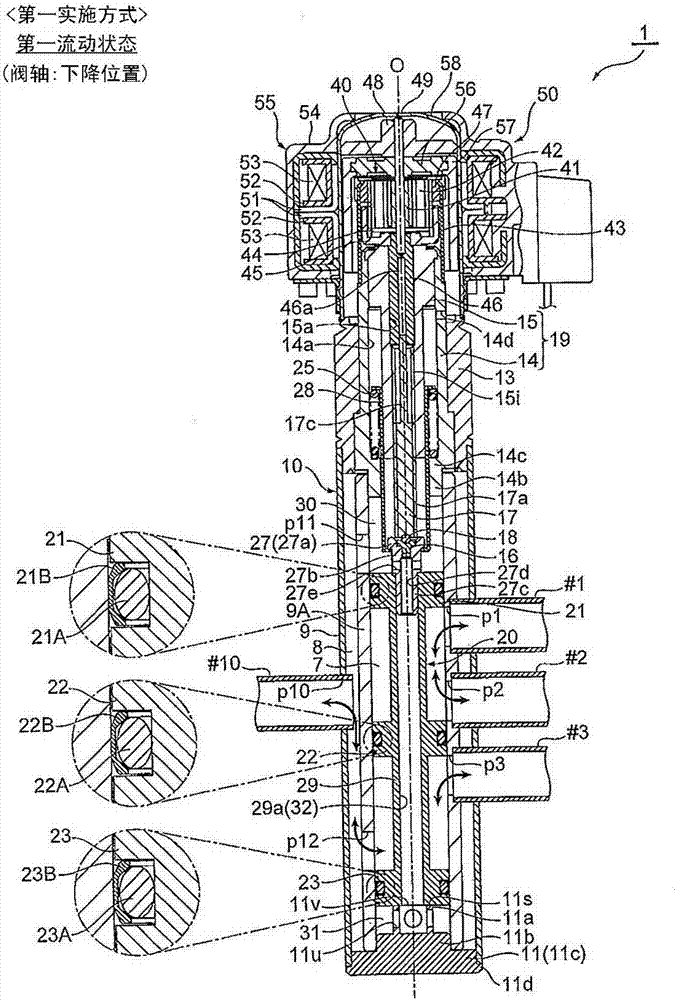

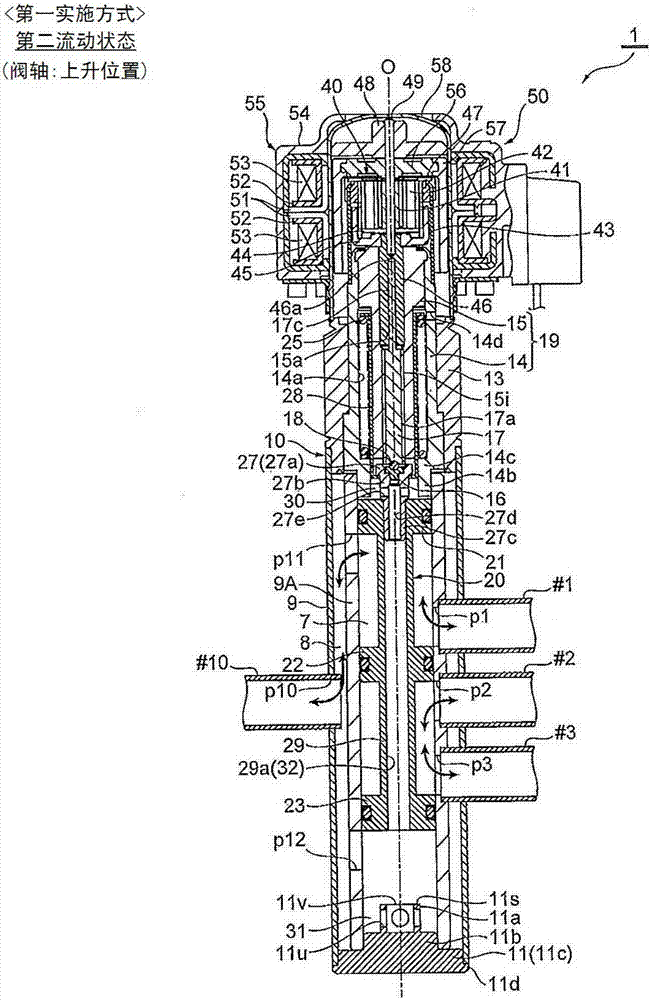

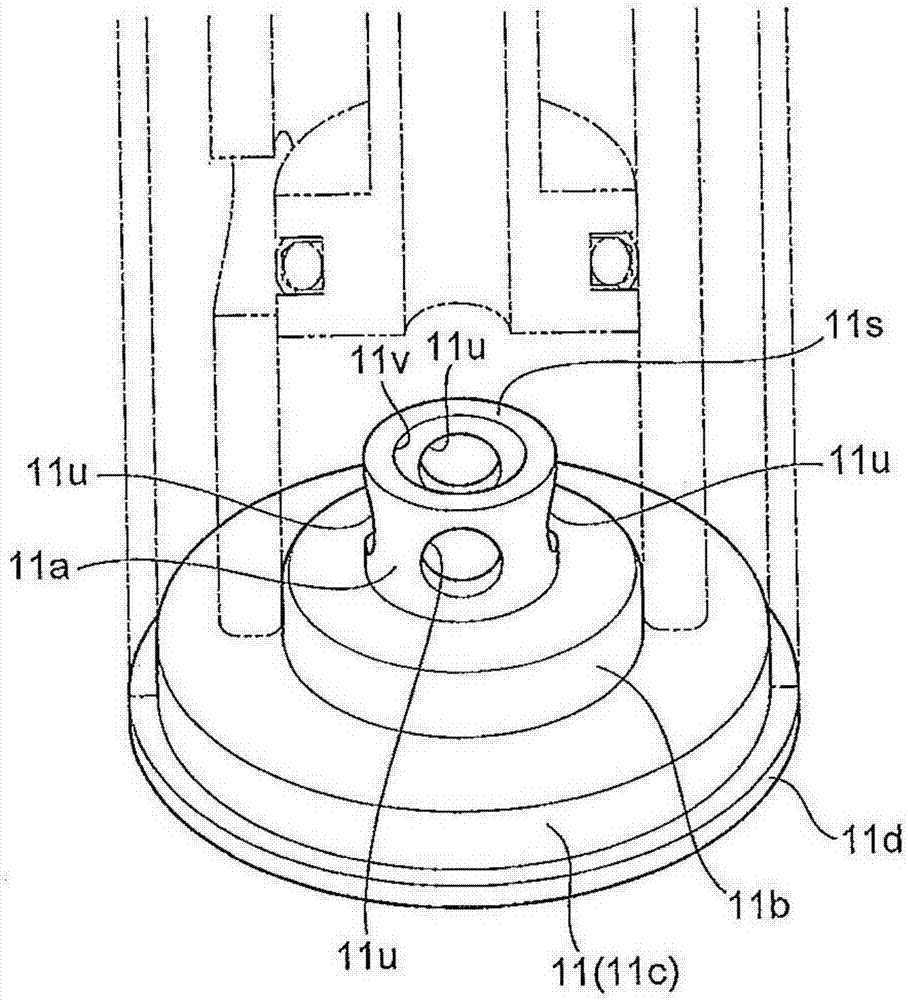

[0082] figure 1 and figure 2 It is a longitudinal sectional view showing the first embodiment of the channel switching valve of the present invention, figure 1 Indicates the first flow state (valve shaft: down position), figure 2 Indicates the second flow state (valve shaft: raised position).

[0083] In addition, in this specification, descriptions indicating positions and directions such as up and down, left and right, and front and rear are added for the convenience of the drawings to avoid cumbersome description, and are not limited to the positions and directions shown in the actual use state. direction.

[0084] In addition, in each figure, there are cases in which the gaps formed between components, the spacing distance between components, etc., are larger than the size of each component for easy understanding of the invention or for convenience in drawing. Or reduced to depict.

[0085] The flow path switching valve 1 of this embodiment is, for example, an elect...

no. 2 approach

[0113] Figure 4 as well as Figure 5 It is a longitudinal sectional view showing the second embodiment of the channel switching valve of the present invention, Figure 4 Indicates the first flow state (valve shaft: down position), Figure 5 Indicates the second flow state (valve shaft: raised position).

[0114] The channel switching valve 2 of the second embodiment differs from the channel switching valve 1 of the above-mentioned first embodiment basically only in the number of inner ports formed in the inner housing and the number of spools formed in the valve shaft. Therefore, components having the same functions as those in the first embodiment are denoted by the same symbols and their detailed descriptions are omitted, and only the above-mentioned differences will be described in detail below.

[0115] The flow path switching valve 2 of this embodiment is used as a six-way switching valve in, for example, a heat pump type refrigeration and heating system, etc., and th...

no. 3 approach

[0124] Figure 8 as well as Figure 9 It is a longitudinal sectional view showing the third embodiment of the channel switching valve of the present invention, Figure 8 Indicates the first flow state (valve shaft: down position), Figure 9 Indicates the second flow state (valve shaft: raised position).

[0125] Compared with the channel switching valve 2 of the above-mentioned second embodiment, the channel switching valve 3 of the third embodiment is basically different in the opening position of the outer port and the shape of the communication space between the outer case and the inner case. different. Therefore, components having the same functions as those in the second embodiment are denoted by the same symbols and their detailed descriptions are omitted, and only the above-mentioned differences will be described in detail below.

[0126] The channel switching valve 3 of the present embodiment is used as a six-way switching valve in, for example, a heat pump cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com