Interactive coupling numerical simulation method of temperature field in autoclave forming of composite materials

A technology of autoclave forming and composite materials, which is applied in special data processing applications, design optimization/simulation, calculation, etc. Effects of Temperature Field Deviation Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

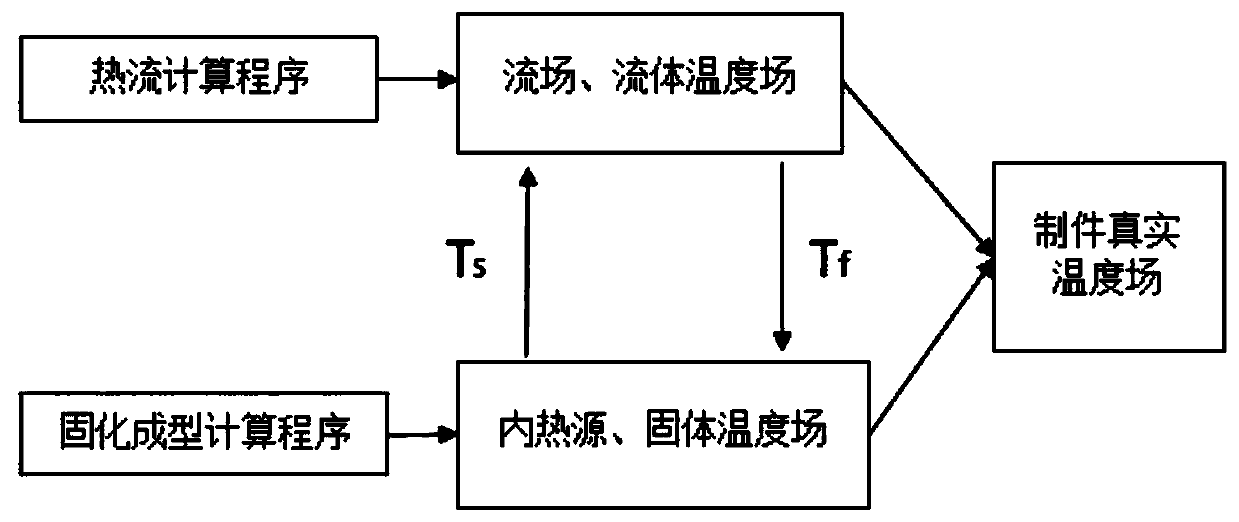

Method used

Image

Examples

Embodiment Construction

[0056] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

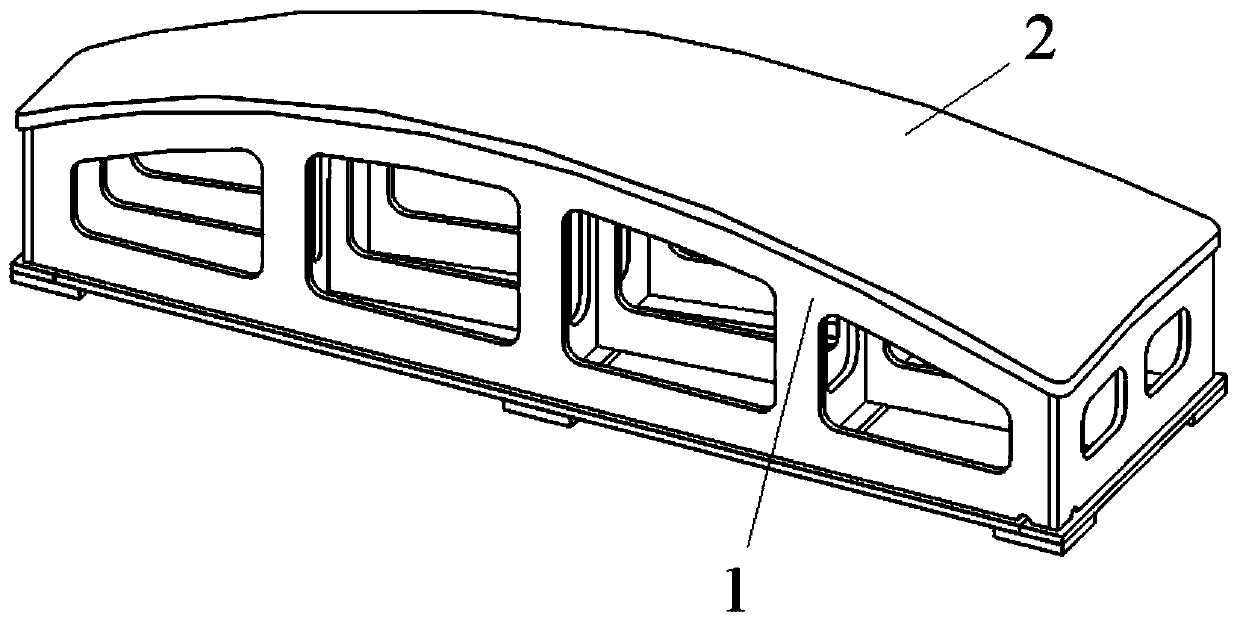

[0057] see figure 1 The mold, the mold size in this embodiment is length * width * height = 1.24 * 0.4 * 0.3m, the mold adopts a frame support structure, the mold material is invar steel, and the mold surface is a melon petal-shaped hyperboloid.

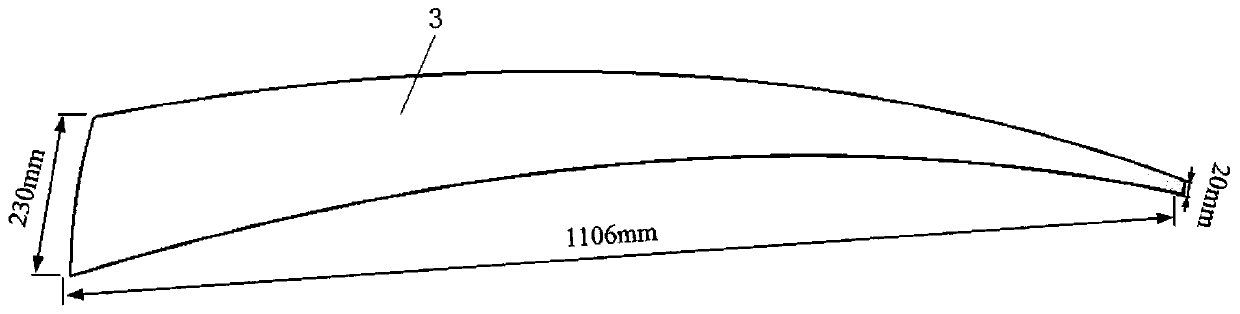

[0058] see figure 2 The melon petal-shaped member, in this embodiment, the member size is length×width×thickness=1106×(20~230)×1.4mm, the member material is T800 / epoxy resin prepreg, and the layup is single along the length direction of the member 8 layers are laid in total. Due to the symmetry of the structure of components and molds, in order to save computing resources, this embodiment only takes half of the components and molds for simulation analysis.

[0059] The effective internal size of the autoclave ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com