A Calcination Tail Gas Treatment Device

A technology for exhaust gas treatment and exhaust device, which is applied in the direction of combination device, separation method, dispersed particle separation, etc., can solve the problems of low recovery efficiency, large water consumption, easy deposition of particles on the pipe wall, etc., and achieves good purification effect. The effect of improving recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the technical solutions in the present application, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application. Obviously, the described The embodiments are only some of the embodiments of the present application, but not all of them.

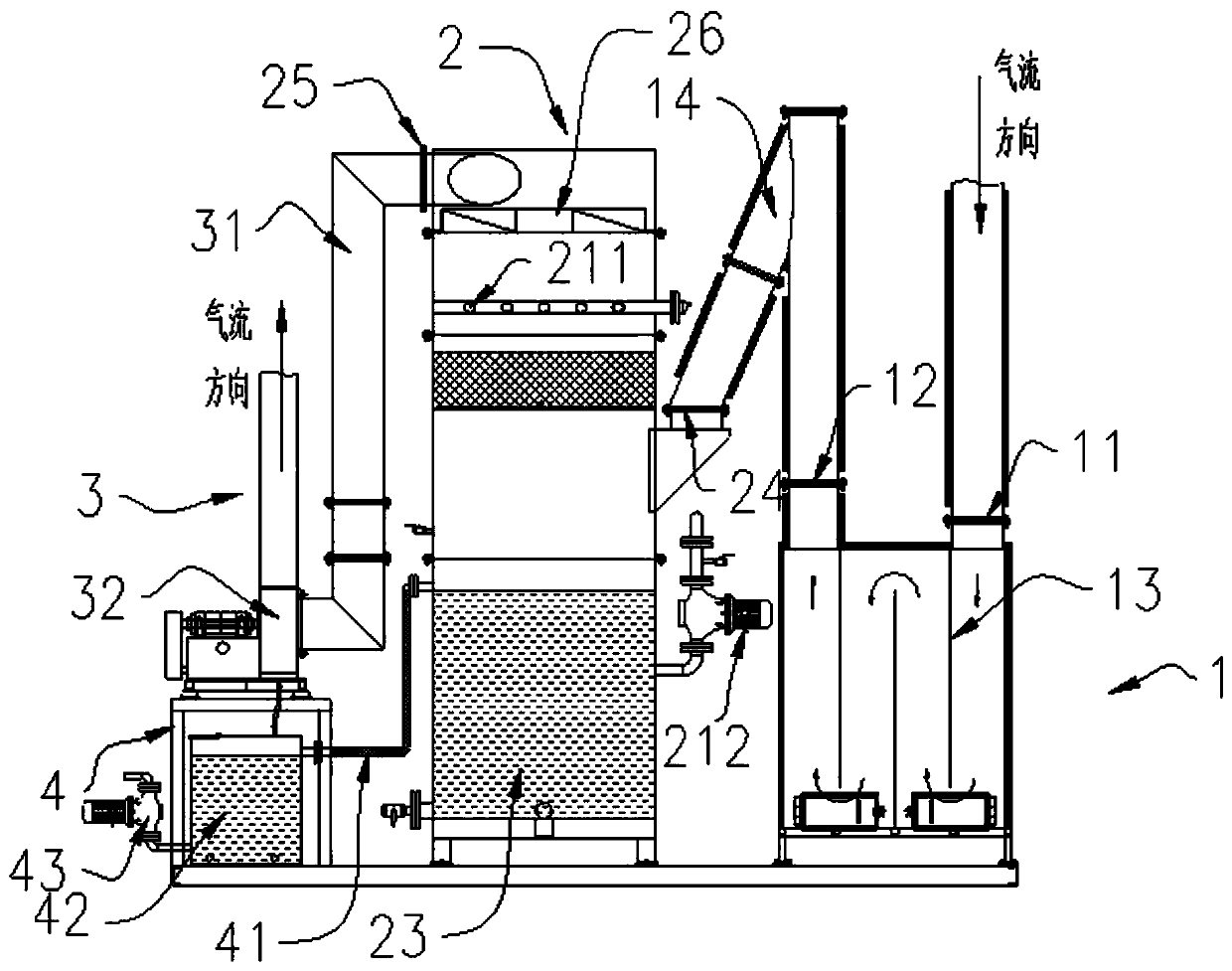

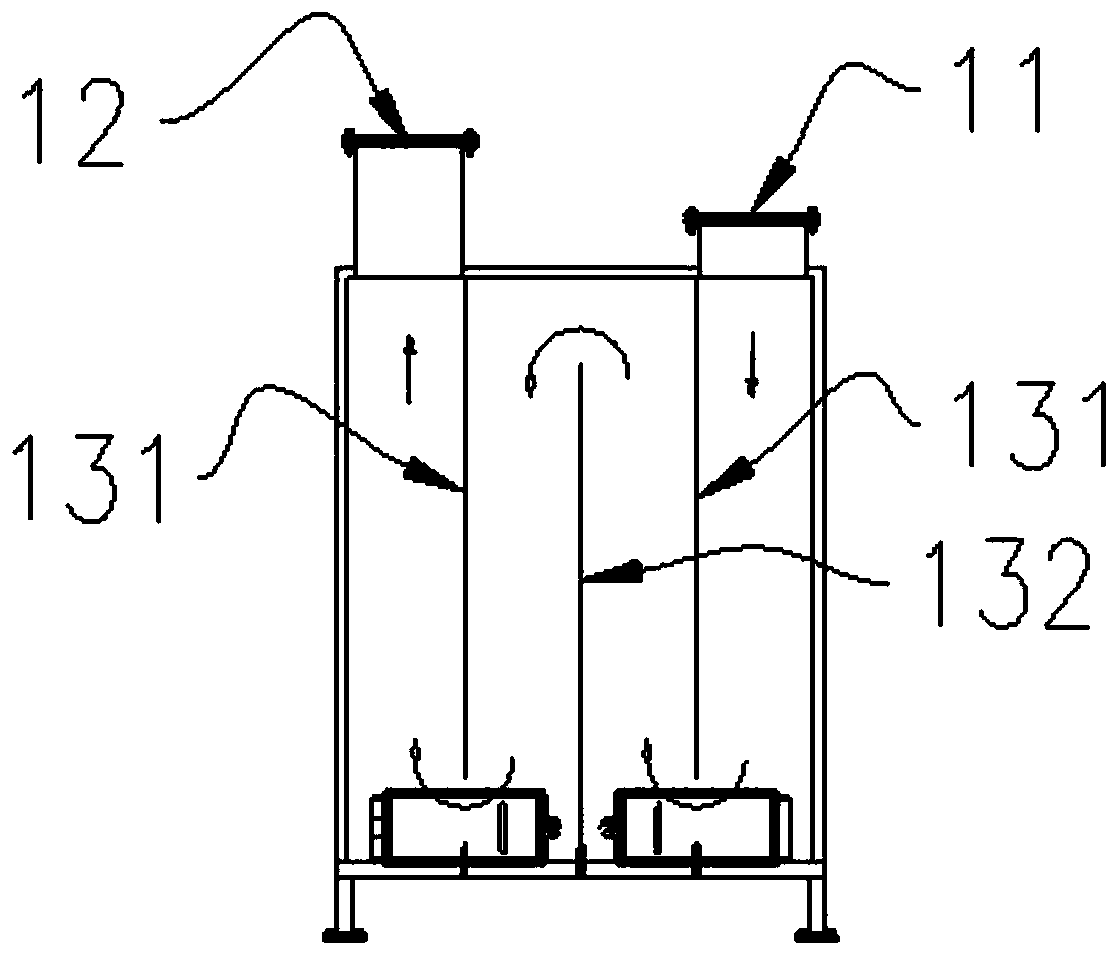

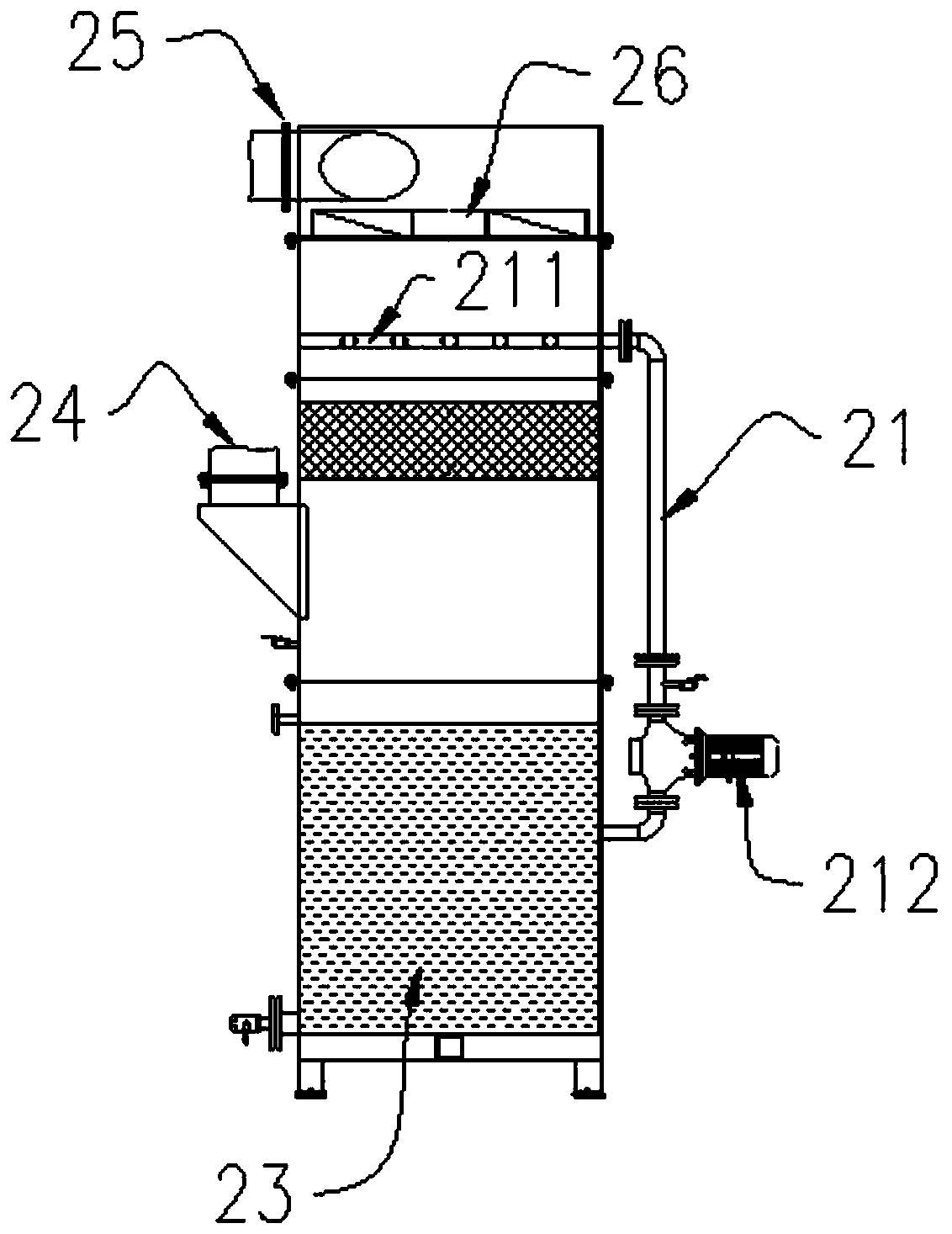

[0021] Please refer to Figure 1 to Figure 3 , the present embodiment provides a calcination tail gas treatment device, including a deposition device 1, a rinsing device 2 and an exhaust device 3, the deposition device 1 is provided with a deposition inlet 11 and a deposition outlet 12, and the deposition inlet 11 A baffle plate 13 is provided between the deposition exhaust port 12; the gas fills the deposition air inlet 11 and enters the deposition device 1, flows back and decelerates through the baffle plate 13, and flows out from the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com