Laser equipment for automatically processing shoe and boot components

A technology of laser equipment and shoes, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of low degree of automation, cumbersome operation process, and low production efficiency, and achieve high degree of automation, reliable transmission performance, The effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

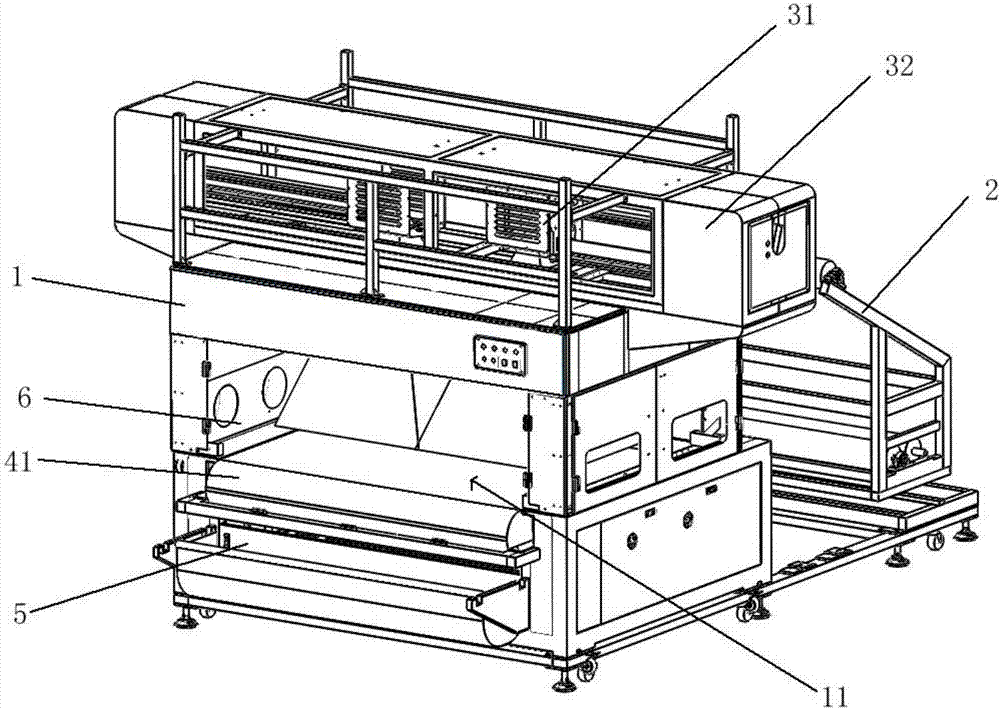

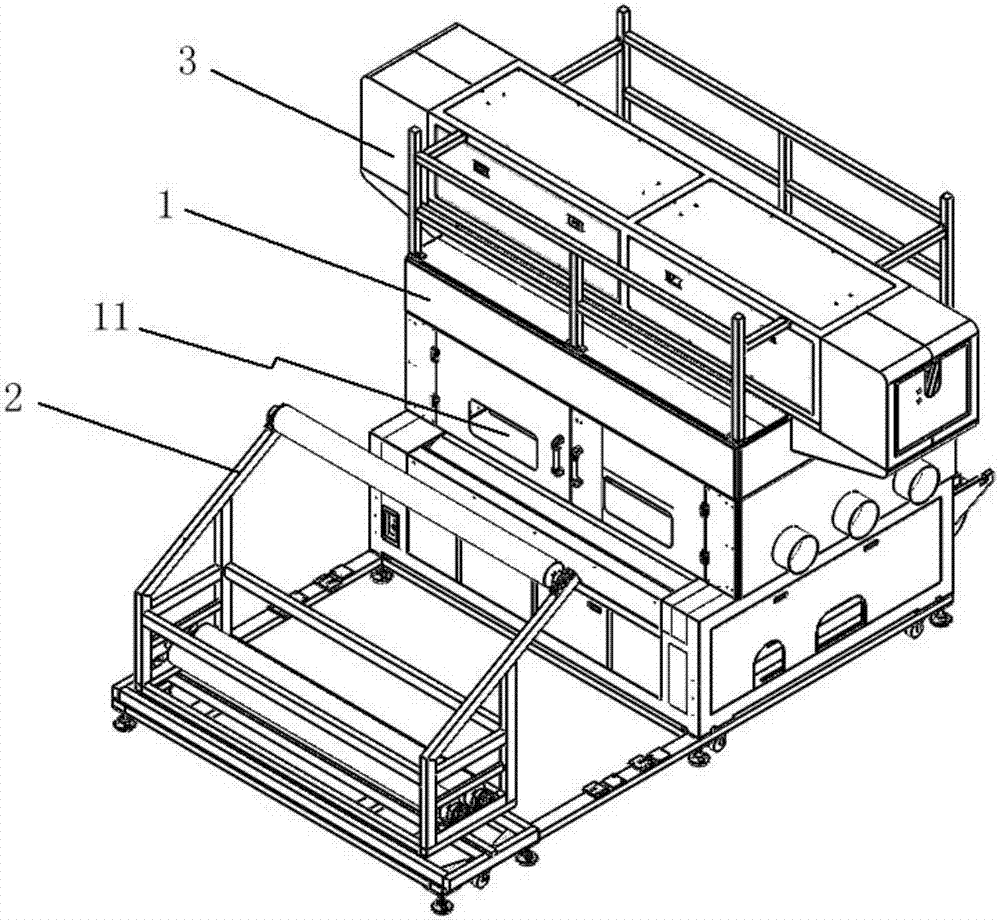

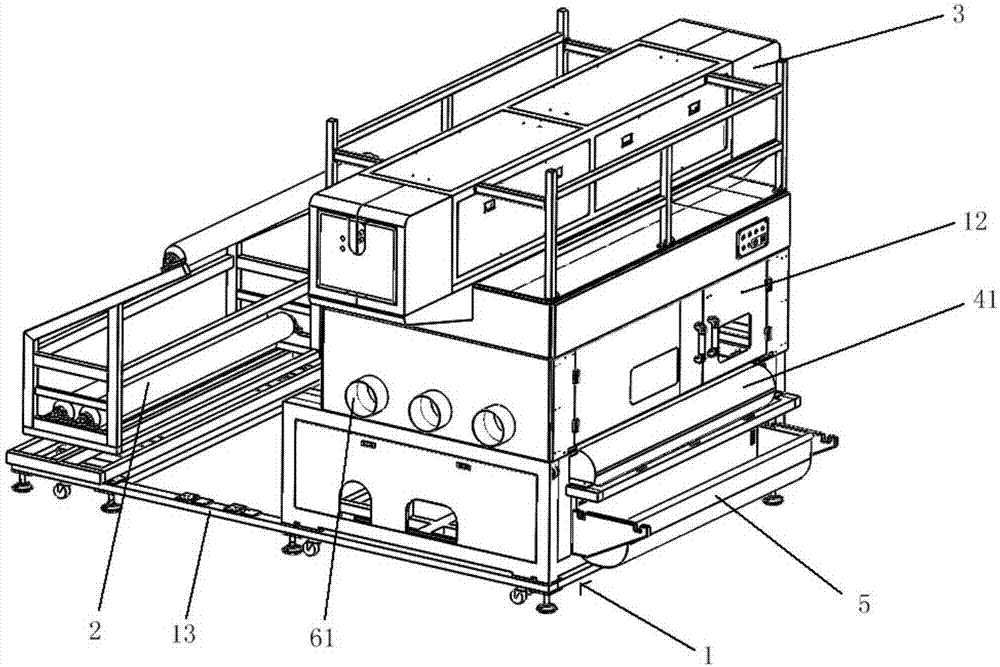

[0046] This embodiment provides as Figure 1-8 A laser device for automatic processing of shoe parts is shown, including a device body, a conveying device, an adsorption device and a laser operating device. The device body 1 includes a working area 11 for accommodating shoe fabrics; On the equipment body 1, there is a feeding mechanism 2 for conveying the shoe material into the working area 11 flatly, and a feeding mechanism 2 arranged in the working area 11 for conveying the shoes on it The transmission mechanism of the fabric; the adsorption device is arranged at the bottom of the equipment body 11, and is used to suck the shoe fabric on the working area 11; wherein, the laser operating device 3 is set on the working area corresponding to the The top of the equipment body 1 includes two laser scanning mechanisms 31 and an adjustment mechanism for controlling the installation positions of the two laser scanning mechanisms 31. The adjustment mechanism adjusts the correspondenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com