Control device and control method for stabilizing pressure of pneumatic branch pipe network

A technology of control devices and branch pipes, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as pressure fluctuations in pneumatic pipe networks and affect normal production of production lines, and achieve energy saving, consumption reduction, and improvement The overall air supply quality and the effect of improving the number of opening units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

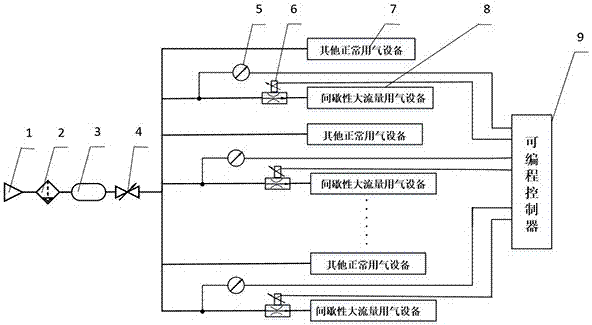

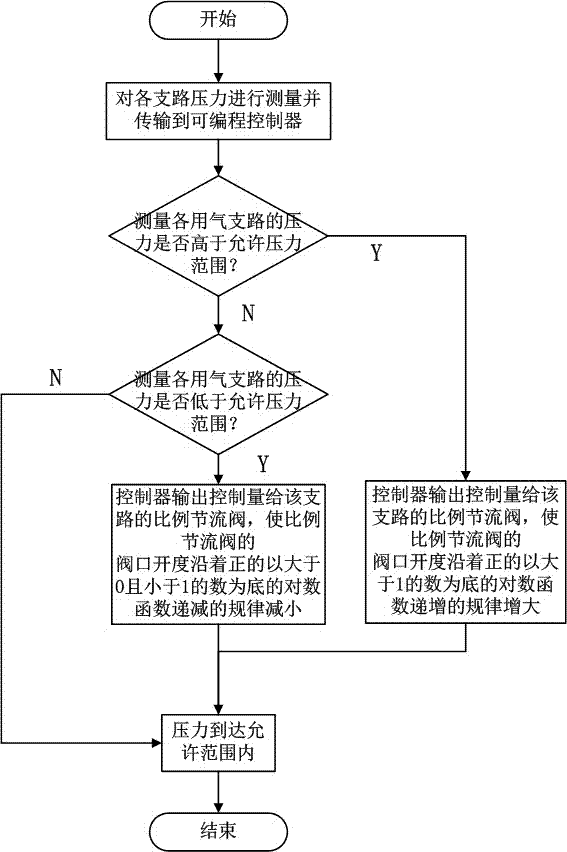

[0020] Such as figure 1 As shown, a control device for stabilizing the pressure of the pneumatic branch pipe network consists of an air source (1), a separator (2), an air storage tank (3), a stop valve (4), a pressure sensor (5), and a proportional Throttle valve (6), other normal gas consumption equipment (7), intermittent large flow gas consumption equipment (8), and programmable controller (9).

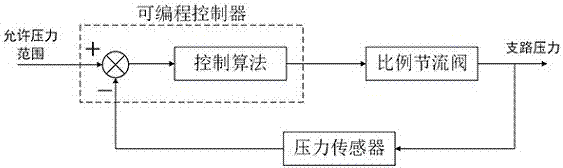

[0021] Among them, the pressure sensor (5) of each gas branch is used to collect the pressure value of each gas branch and transmit it to the programmable controller (9); the programmable controller (9) controls the pressure of each gas branch The value is processed, and the processing result is output to the proportional throttle valve (6).

[0022] according to figure 1 As shown, install the pressure sensors (5) and programmable controllers (9) of each gas branch on the pneumatic pipe network system, open the pneumatic system and control device, and set them in the programmabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com