Dewatering and drying machine for plastic products

A dehydration drying and product technology, which is applied in dryers, machine tools suitable for grinding workpiece edges, drying and other directions, can solve the problems of incomplete drying, difficult and difficult control of drying temperature, etc. Save the time of polishing and deburring, prevent incomplete drying, and avoid the effect of partial drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

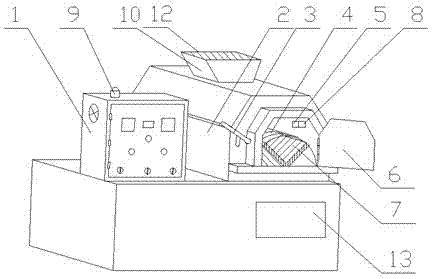

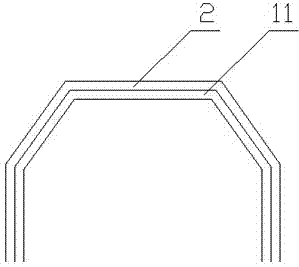

[0011] A dehydration dryer for plastic products, comprising: a control box 1, a drying box 2, a lock valve 3, a rotating cylinder 4, a temperature sensor 5, a drying box door 6, a shelf 7, and a humidity sensor 8 , high temperature alarm light 9, discrete agent placement port 10, electromagnetic heating plate 11, dust cover 12, high temperature alarm 9 lights are installed on the top of control box 1, drying box 2 is installed on one side of control box 1, and drying box 2 is installed on one side Drying box door 6, door lock valve 3 is installed on one side of drying box door 6, electromagnetic heating plate 11 is installed on the inner surface of drying box 2, temperature-sensing probe 5 is installed in drying box 2, and humidity sensor is installed on one side of temperature-sensing probe 5 Device 8, rotating cylinder 4 is installed in the drying box 2, and installation rack 7 is installed in the rotating cylinder 4, and the drying box 2 top offers the discrete agent placeme...

Embodiment 2

[0013] The staff opens the drying box door 6, puts the plastic products on the rack 7 in the rotating cylinder 4, closes the drying box door 6 after placing them, and locks the drying box 2 through the lock valve 3 to prevent the plastic products from being damaged during the drying process. Plastic products fly out when rotating, open the dust cover 12, add an appropriate amount of dispersant to the drying box 2, close the dust cover 12, turn on the equipment, the temperature and humidity in the drying box 2 are displayed on the control box 1, and the staff The temperature of the electromagnetic heating plate 11 can be adjusted through the control box 1 to make it lower than the aging temperature of the plastic in the box. The rotating cylinder 4 drives the plastic products in the cylinder to rotate, increasing its heating surface, avoiding its local overheating, and increasing the drying efficiency. When the temperature in the box 2 is too high, the temperature-sensing probe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com