Anti-sticking meat paste processing machine

An anti-adhesion and processing machine technology, which is used in meat processing, slaughtering, food science, etc., can solve the problems of splashing, waste, and insufficient hygiene of minced meat raw materials, and achieve the effect of ensuring quality and flavor, saving resources and energy, and rational layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below by embodiment the content of the present invention is specified:

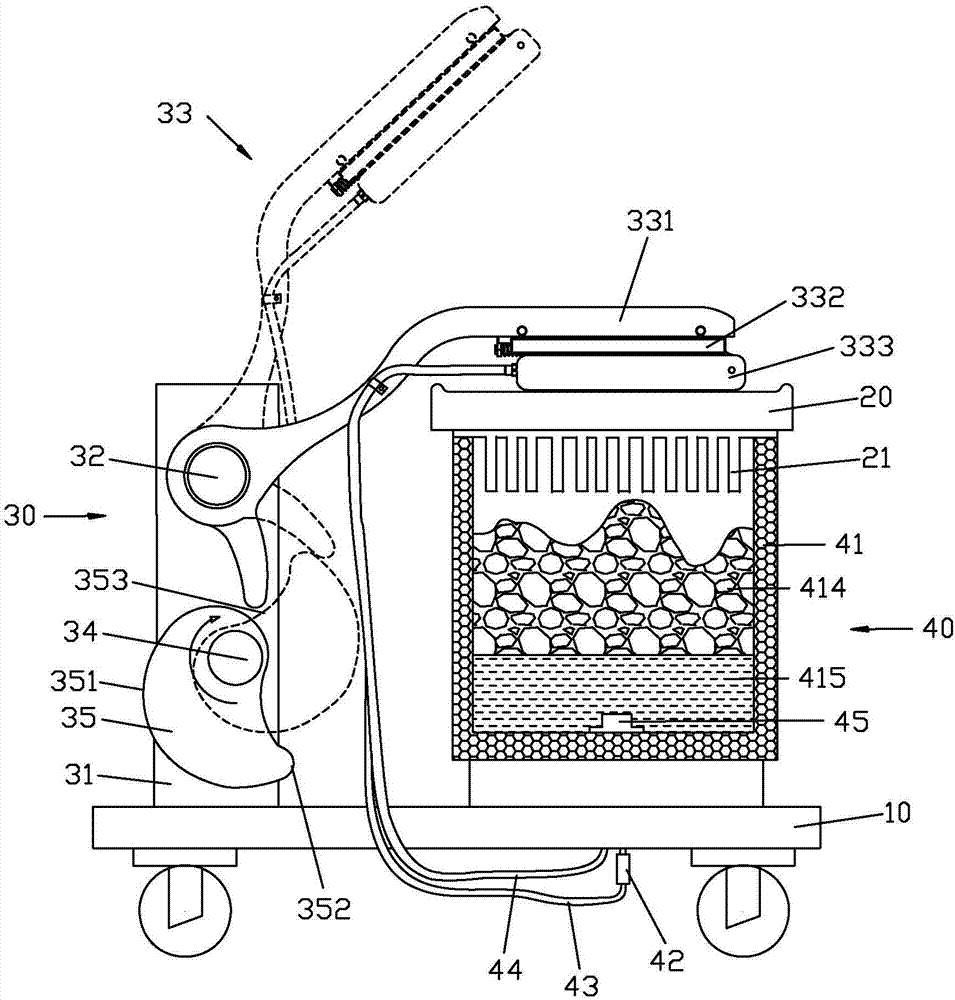

[0040] Please check figure 1 , an anti-adhesion minced meat processing machine, the base 10 is provided with a cutting board 20, a beating mechanism 30 and a circulating cooling mechanism 40;

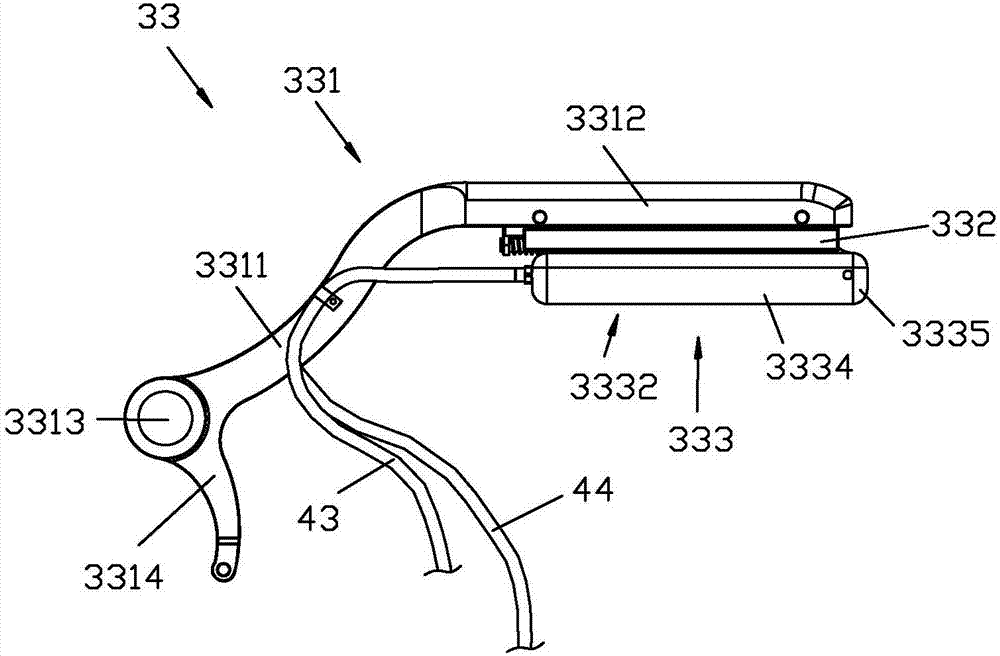

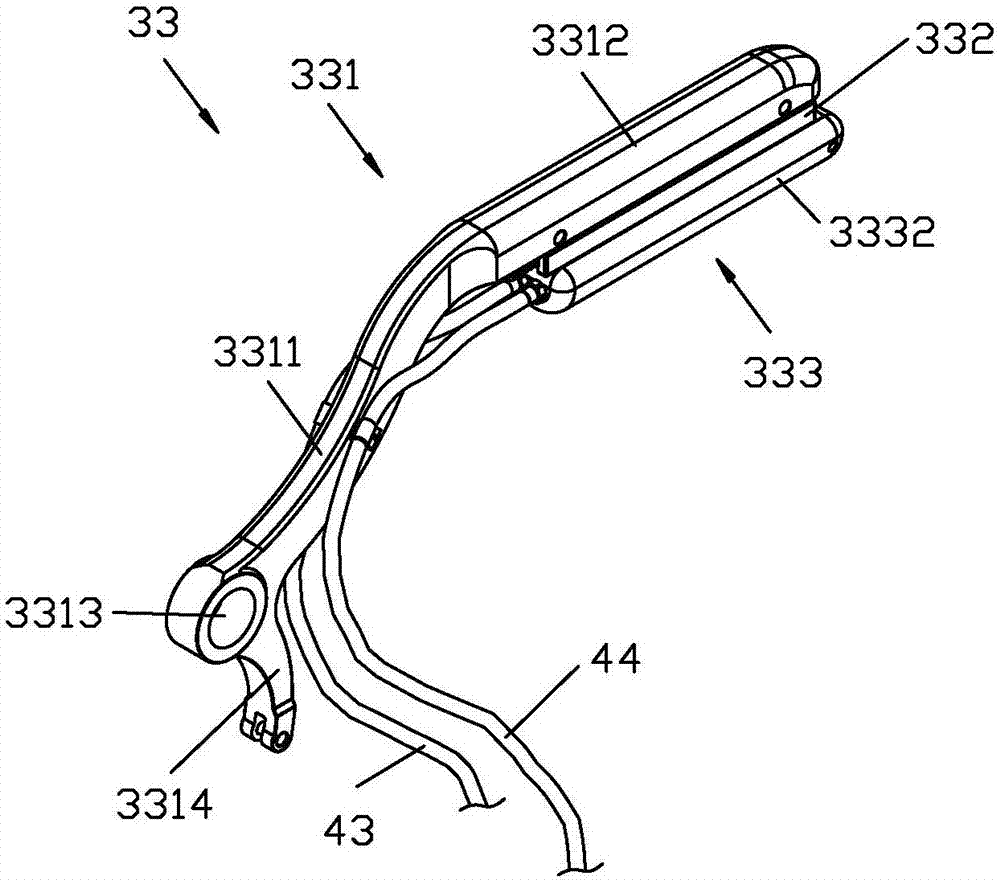

[0041] Beating mechanism 30 comprises frame 31, swing shaft 32, mallet assembly 33, throwing line camshaft 34, line throwing cam 35, and frame 31 is installed on the rear side on the base 10, and frame 31 top is provided with at least one swing shaft 32, each swing shaft 32 is pivotally connected to a mallet assembly 33; at least one throwing camshaft 34 is arranged in the middle of the frame 31, and each throwing camshaft 34 is pivotally connected to a throwing cam 35; the throwing cam 35 has a Pushing arc 351 , crown 352 and relief groove 353 protruding outward. Please check Figure 2 to Figure 5 , the mallet assembly 33 includes a pounding mallet 331, a transition plate 332 and a metal mallet head 333:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com