Reverse multi-angle blowing and drying device

A drying device, multi-angle technology, applied in the direction of drying gas arrangement, spraying device, spraying device, etc., can solve the problems of affecting the cooling effect, heavy drying device, cooling water residue, etc., to promote the combined discharge of water and gas, and the combination is fast and accurate , Finished surface smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

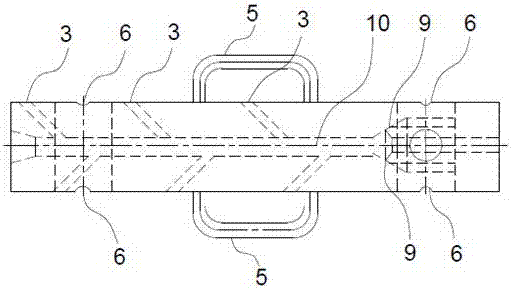

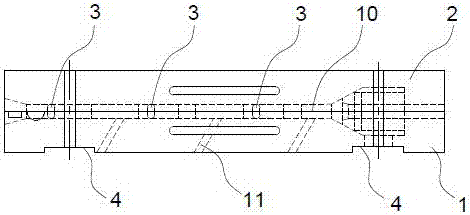

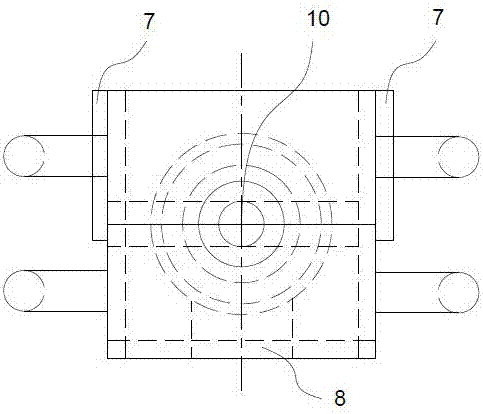

[0034] A kind of reverse multi-angle purging and drying device of this embodiment, its basic structure is the same as that of Embodiment 1, and there are 6 decompression splitter grooves 3 distributed asymmetrically on both sides of the steel hole 10, and every two adjacent different The side decompression shunt grooves 3 are one group, and there are 3 groups in total. The difference is that the angle between the axial direction of the decompression shunt groove 3 and the axial direction of the steel hole 10 is 45°, that is, in the decompression shunt groove 3 The angle between the flow direction of the compressed air and the reverse direction of rolling is 45°, the distance between the decompression shunt trough 3 adjacent to the same side of the steel hole 10 and the junction of the steel hole 10 is 120 mm, and the distance between the adjacent pressure relief grooves 3 on the same side of the steel hole 10 is 120 mm. The distance between the junctions of the pressure splitte...

Embodiment 3

[0036] A kind of reverse multi-angle purging and drying device of this embodiment, its basic structure is the same as that of Embodiment 1, and there are 6 decompression splitter grooves 3 distributed asymmetrically on both sides of the steel hole 10, and every two adjacent different The side decompression shunt grooves 3 form a group, and there are 3 groups in total. The difference is that the angle between the axial direction of the decompression shunt groove 3 and the axial direction of the steel hole 10 is 55°, that is, in the decompression shunt groove 3 The included angle between the flow direction of the compressed air and the reverse direction of rolling is 55°, the distance between the decompression shunt trough 3 adjacent to the same side of the steel hole 10 and the junction of the steel hole 10 is 150mm, and the adjacent pressure reduction groove 3 on the same side of the steel hole 10 is 150mm. The distance between the junctions of the pressure splitter grooves 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com