Method used for producing camptothecin and 10-hydroxycamptothecine with camptotheca acuminate suspension cells

A technology of hydroxycamptothecin and suspension cells, which is applied in the field of medicine and biology, can solve the problems of low product content, and achieve rapid growth and reproduction, simple and easy-to-control methods, and easy-to-cultivate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Establishment of camptophylla aseptic seedlings

[0025] 1. Test material

[0026] 1.1 Plant material

[0027] Choose the amphocarpa fruit that grows normally and healthy, and peel, clean, and disinfect according to routine operations. In the present embodiment, the seed coat of the fruit is first removed, then soaked with 5% Triton for 3 minutes, rinsed repeatedly with sterile water, the concentration is 75% ethanol for 1 minute, 1% sodium hypochlorite solution for 3 minutes, and sterile water for 10 times. 1min, and finally use sterile filter paper to absorb the moisture on the surface of Campylocarpa seeds, and set aside.

[0028] 1.2 Medium

[0029] 1 / 2 MS solid medium: add 0.35% agar (Sigma Chemical, MO) to 1 / 2 MS medium, pH 5.8, autoclave at 121° C. for 30 min.

[0030] 2. Inoculation of seeds into culture medium

[0031] The prepared seeds were inoculated and cultivated according to conventional aseptic methods.

[0032] Inoculate the prepared se...

Embodiment 2

[0033] Embodiment two: the establishment of camptophylla callus

[0034] 1 test material

[0035] 1.1 Plant material

[0036] The aseptic seedling that obtains among the embodiment one. According to routine aseptic operation, cut the leaves into small pieces of 10 mm×10 mm with a sterile scalpel, and set aside.

[0037] 1.2 Medium

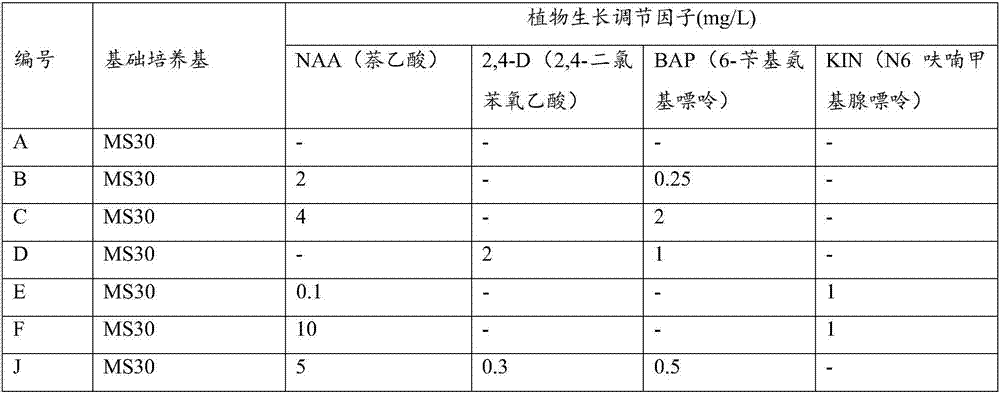

[0038] 7 kinds of solid medium based on MS30 (30mg / L sucrose added to MS medium) and different compositions and concentrations of growth regulators. As in Table 1:

[0039] Table 1 Composition of Medium A-J

[0040]

[0041] 2. Inoculation of sterile leaves into culture medium

[0042] The prepared leaves were inoculated and cultured according to conventional aseptic methods.

[0043] Inoculate the prepared leaves on the corresponding medium in Table 1, and culture them in the dark at 25°C for 5-6 weeks until the callus grows. Three parallel experiments were performed on different media.

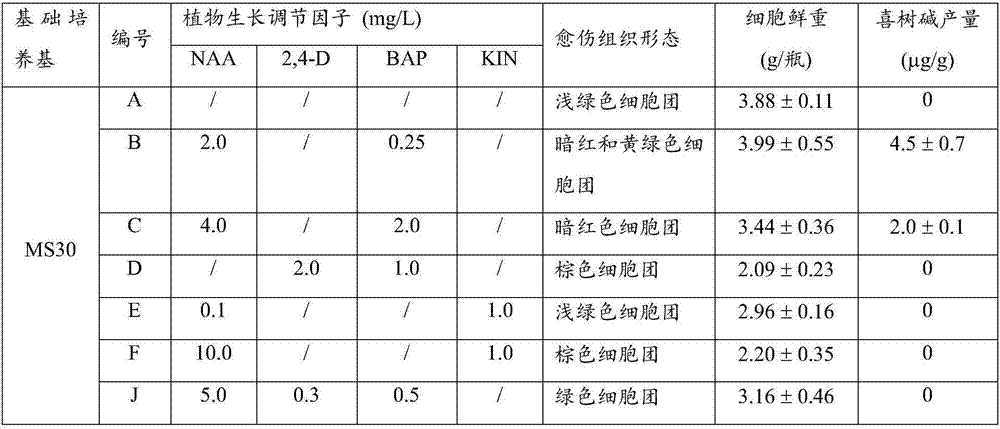

[0044] 3. Preparation of Metabolites from Campylo...

Embodiment 3

[0057] Example 3: Establishment of Campylocarpa suspension cell line

[0058] 1 test material

[0059] 1.1 Plant material

[0060] The Campylocarpa callus obtained in Example 2 was cut into small pieces with a sterile scalpel according to conventional aseptic procedures, and was set aside.

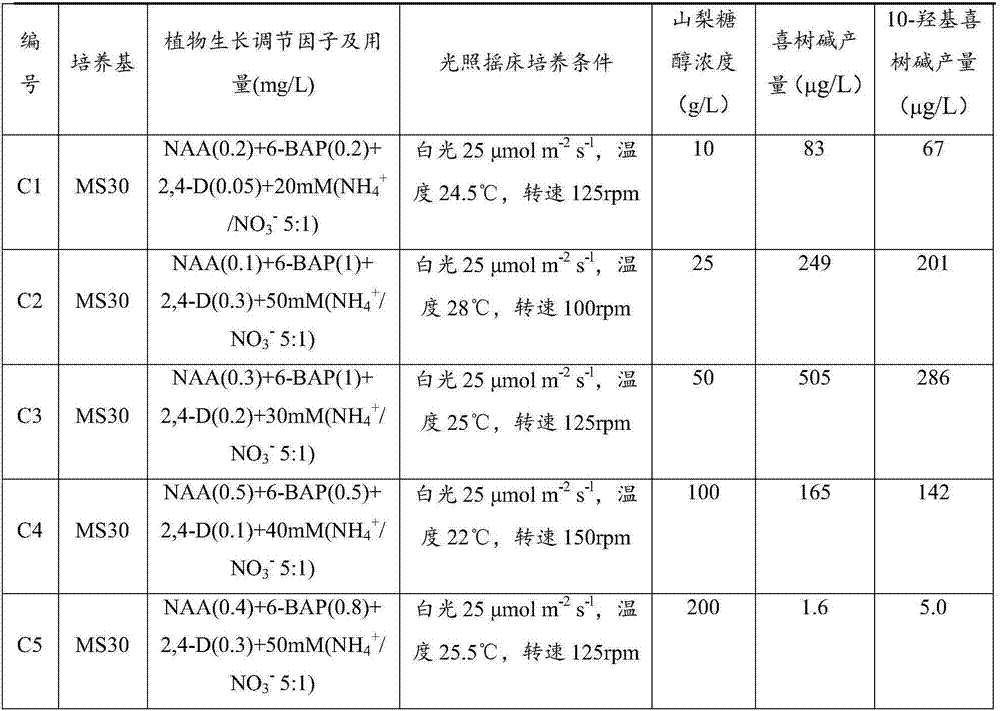

[0061] 1.2 Medium

[0062] Add 0.5mg / L NAA and 2mg / L BAP to MS30 liquid medium.

[0063] 2. Inoculation of Campylodon japonica callus into culture medium

[0064] The prepared callus was inoculated and cultured according to conventional aseptic methods.

[0065] The callus was inoculated into 100mL liquid medium and cultured under continuous light. Light culture conditions: white light (25 μmol m -2 the s -l ), the temperature is 25° C., the humidity is 70%, and the rotation speed is 125 rpm. After 3 to 5 days, when cells grow out of the culture medium, absorb 5 mL of the cell suspension and transfer it to 100 mL of a new liquid medium, and culture under the same conditions to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com