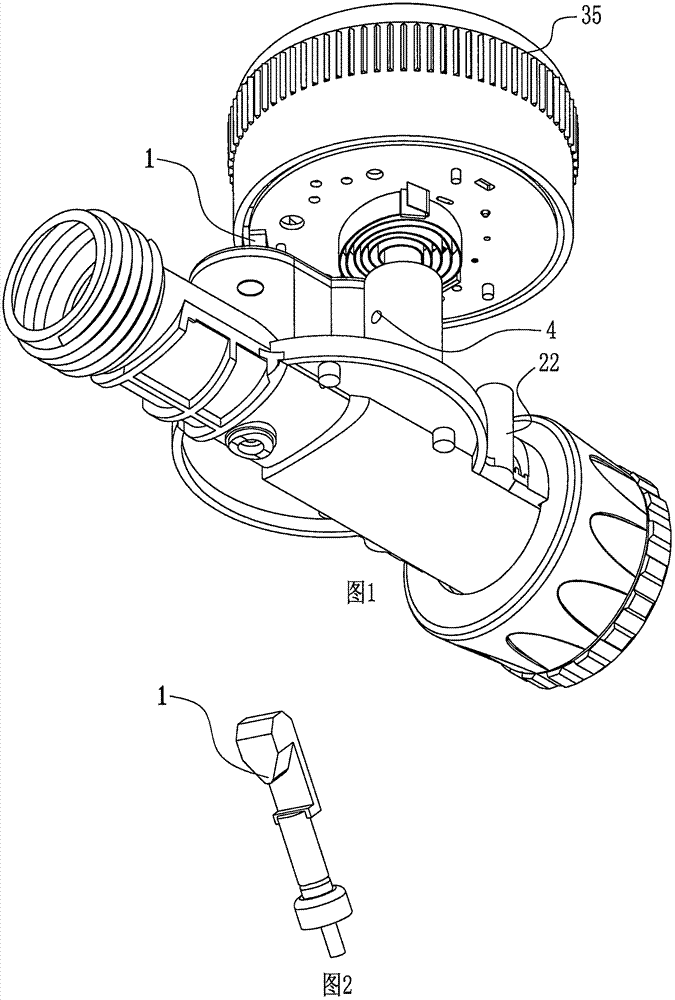

Improved adjustable and swing water sprayer

A swinging sprinkler and sprinkler technology, applied in watering devices, gardening, botanical equipment and methods, etc., can solve the problems of incompleteness, inability to have a 360-degree all-round irrigation effect, and high cost of metal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

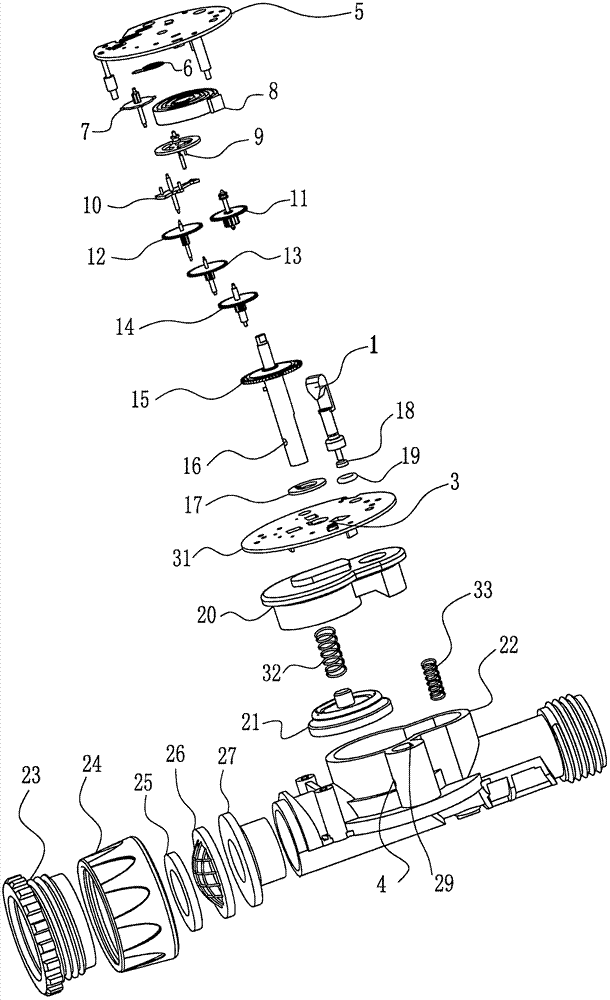

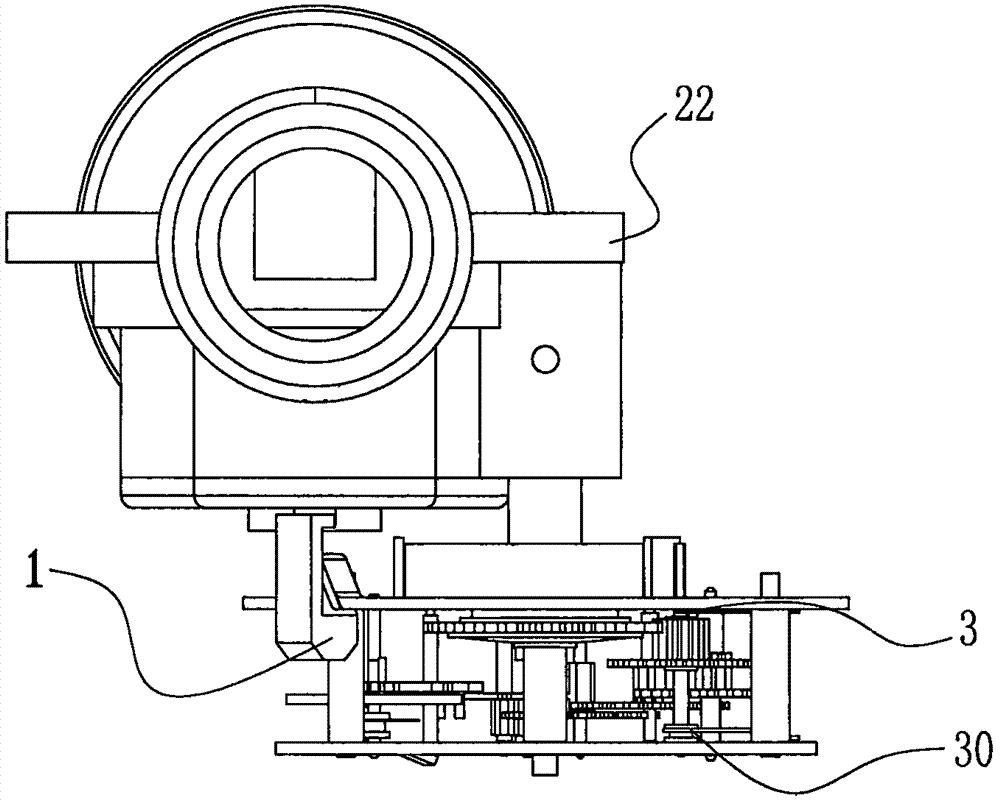

[0107] Operators often run into trouble, that is, the water source has no interface, but only a faucet. To remove the faucet, in order to access the sprinkler timer. But sometimes there are no suitable tools at hand, and sometimes the faucet is difficult to remove due to long-term corrosion, and it has to be installed after it is used up. Because the improvement of this energy-saving sprinkler timer is provided with a multi-purpose interface, it is after the inner plug 27, the filter screen 26, the gasket 25, the knob 24, and the nut 23 are loaded into the switch main body 22 in turn, and then installed in turn. Outer threaded joint 37, inner interface core 40, soft rubber joint 39, multi-groove clamp 38 and butterfly worm 36 are formed, and these have been installed when leaving the factory, so the operator only needs to put the described After the soft rubber joint 39 is inserted into the water tap, tighten it with the multi-groove clamp 38 and the butterfly worm screw 36 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com