Preparation method of SPI (soybean protein isolate)

A technology of soybean protein isolate and protein slurry, which is applied in the field of food and food processing, can solve the problems that the quality of soybean protein isolate products cannot be fundamentally improved, restrict the development of the domestic protein beverage market, etc., and achieve the reduction of bad flavor substances and harmful substances, The effect of improving product flavor and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

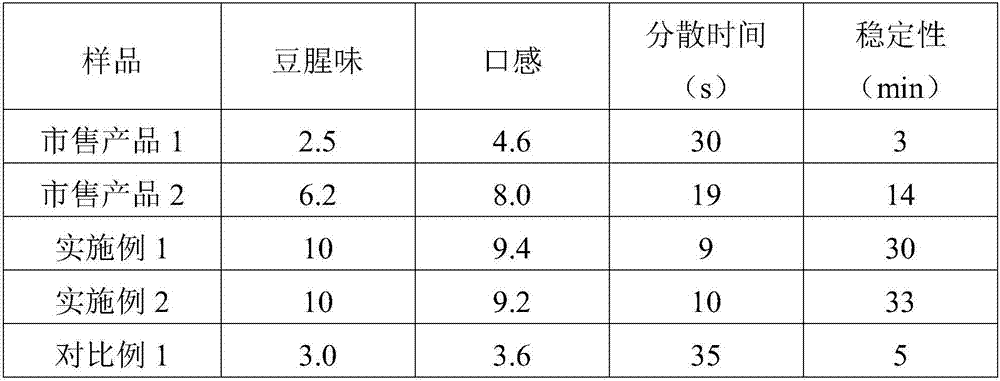

Examples

Embodiment 1

[0041] A soy protein isolate

[0042] The preparation method is as follows:

[0043] (1) Extraction: Add 12 times the amount of water to the defatted soybean meal, the water temperature is 25°C, the pH value is adjusted to 6.5 with liquid NaOH, and the extraction is stirred for 50 minutes at a stirring speed of 60-70r / min; after the extraction is completed, The extract is centrifuged to obtain solid phase component 1 and liquid phase component 1. Add 7 times the amount of defatted soybean meal to the solid phase component 1, and carry out the second stirring and extraction for 10 minutes at a stirring speed of 60-70r / min; After the second extraction is completed, the extract is centrifuged to obtain solid phase component 2 and liquid phase component 2;

[0044] (2) One-time sterilization and flash evaporation: mix the above liquid phase component 1 and liquid phase component 2 uniformly, carry out high-temperature instantaneous sterilization, sterilization time 20s, sterilization t...

Embodiment 2

[0052] A soy protein isolate

[0053] The preparation method is as follows:

[0054] (1) Extraction: Add 15 times the amount of water to the defatted soybean meal, the water temperature is 40°C, the pH value is adjusted to 7.5 with liquid NaOH, and the extraction is stirred for 60 minutes at a stirring speed of 60-70r / min; after the extraction is completed, The extract is centrifuged to obtain solid phase component 1 and liquid phase component 1. Add 6 times the amount of defatted soybean meal to the solid phase component 1, and carry out the second stirring and extraction for 10 minutes at a stirring speed of 60-70r / min; After the second extraction is completed, the extract is centrifuged to obtain solid phase component 2 and liquid phase component 2;

[0055] (2) One-time sterilization and flash evaporation: mix the above-mentioned liquid phase component 1 and liquid phase component 2 uniformly, carry out high-temperature instantaneous sterilization, sterilization time 40s, steri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com